Description

| Model | RXEDK 2H 1MRK000841-KA |

| Brand | ABB |

| Type | Residual Current Monitoring Relay |

| Rated Voltage | 230V AC / 400V AC (phase-to-phase) |

| Measurement Range | 30 mA to 1000 mA (adjustable) |

| Accuracy | ±5% of measured value |

| Response Time | < 100 ms at rated threshold |

| Mounting | DIN rail mounting (35mm) |

| Dimensions | 45mm x 105mm x 120mm (W x H x D) |

| Weight | 0.25 kg |

| Outputs | 1 x relay output, 1 x analog 4-20mA output |

| Environmental Rating | IP20 (suitable for panel mounting) |

| Certifications | IEC 61010-1, IEC 62020, CE |

RXEDK 2H 1MRK000841-KA

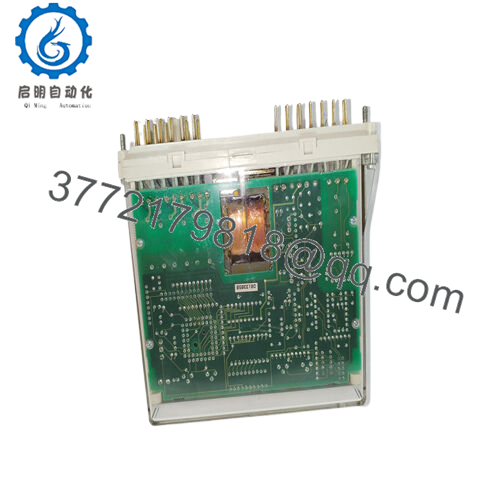

The ABB RXEDK 2H 1MRK000841-KA is a specialized residual current monitoring relay that detects and measures earth leakage currents in electrical circuits, providing critical safety data without automatically interrupting power flow. As a key component in preventive electrical safety systems, it bridges the gap between basic residual current devices (RCDs) and complex monitoring systems, offering precise measurement capabilities combined with flexible alarm outputs for integration into building management or industrial control systems.

RXEDK 2H 1MRK000841-KA

This relay integrates seamlessly with existing electrical panels and safety architectures, including compatibility with ABB’s RXDS series devices like the ABB RXDS 4. Its design focuses on applications where continuous operation is essential, providing early warning of developing faults while allowing system operators to decide on appropriate action. What makes the ABB RXEDK 2H 1MRK000841-KA particularly valuable is its ability to distinguish between harmless transient currents and genuine fault conditions, reducing false alarms while ensuring reliable detection of dangerous current imbalances.

Main features and advantages:

The ABB RXEDK 2H 1MRK000841-KA delivers precise residual current monitoring with measurement sensitivity down to 30 mA, ensuring detection of even minor insulation faults in early stages. It features adjustable threshold settings, allowing customization to specific application requirements—from 30 mA for sensitive electronics to 1000 mA for heavy industrial equipment. The device provides both analog and digital output signals, enabling integration with SCADA systems, BMS platforms, and local alarm panels for comprehensive safety management.

Hardware design highlights include a rugged enclosure that operates reliably in temperatures ranging from -25°C to +70°C, making it suitable for harsh industrial environments and climate-controlled facilities alike. Its compact form factor allows for easy installation in crowded electrical panels, while LED indicators provide instant visual status of operating conditions and fault alerts. The relay’s immunity to electromagnetic interference ensures stable operation even in environments with high electrical noise, such as near large motors or variable frequency drives.

Application areas:

In modern electrical systems, from industrial production lines to commercial building infrastructure, continuous monitoring of residual currents is essential for preventing electrical accidents and minimizing downtime. These environments require specialized devices that can detect even small current imbalances, provide real-time alerts, and integrate with broader safety systems—especially in applications where immediate circuit interruption isn’t desired but early warning is critical. Whether monitoring sensitive medical equipment in healthcare facilities, protecting critical IT infrastructure in data centers, or overseeing complex machinery in manufacturing plants, engineers need reliable residual current monitoring solutions that combine precision with flexible integration capabilities.

This is where the ABB RXEDK 2H 1MRK000841-KA excels, serving as an advanced residual current monitoring relay designed for applications requiring continuous surveillance without automatic tripping. In hospital operating rooms, it provides early warning of insulation degradation in life-support equipment, allowing for scheduled maintenance before faults occur. In data centers, it monitors UPS systems and server racks, alerting technicians to potential ground faults that could disrupt critical operations. Used in safety-critical applications worldwide, the ABB RXEDK 2H 1MRK000841-KA has proven its reliability in scenarios where predictive maintenance and targeted intervention are preferred over immediate circuit shutdown, making it a trusted choice for safety engineers and facility managers.

Related products:

ABB RXDS 4 – Residual current device that works with the ABB RXEDK 2H 1MRK000841-KA in hybrid safety systems, combining monitoring and automatic tripping.

ABB QA/S4.64.1 Energy Analyzer – Integrates with the ABB RXEDK 2H 1MRK000841-KA to correlate energy consumption patterns with residual current trends.

ABB AC500 PLC – Receives data from the ABB RXEDK 2H 1MRK000841-KA for centralized monitoring in industrial automation systems.

ABB HMI60.1 – Local operator panel that displays real-time data from the ABB RXEDK 2H 1MRK000841-KA for on-site monitoring.

ABB SPACOM S200 – Communication gateway that connects the ABB RXEDK 2H 1MRK000841-KA to SCADA systems using standard protocols.

ABB DS204 AC-C40/0.03 – Complementary residual current device that extends protection coverage when paired with the ABB RXEDK 2H 1MRK000841-KA.

ABB RLM01 – Auxiliary relay module that amplifies the alarm outputs of the ABB RXEDK 2H 1MRK000841-KA for complex control schemes.

Installation and maintenance:

Before installing the ABB RXEDK 2H 1MRK000841-KA, verify that the electrical panel provides adequate space with at least 20mm clearance on all sides for wiring and heat dissipation. Ensure the installation location is free from excessive vibration and electromagnetic interference, as these can affect measurement accuracy. Check that the supply voltage matches the device specifications and that the current transformer (if used) is properly sized for the monitored circuit’s current rating.

During installation, mount the relay securely on a 35mm DIN rail and connect the measuring inputs according to the phase sequence specified in the wiring diagram. Configure the threshold settings based on application requirements using the front-panel potentiometer or software tools if applicable. After wiring, perform a functional test using a residual current test device to verify proper operation of both measurement and alarm functions. Document all settings and test results for future reference during maintenance checks.

Other ABB product models:

ABB 3BHE044249R0003

ABB 3BHE046836R0101

ABB 3BHE046836R0102 GFD563A102

ABB 3BHL000250P0002

ABB 3BHL000391P0101 5SHX1445H0001

ABB 3BHL000406P0009

ABB 3BHL000406P0103

ABB 3BHL000519P0001

ABB 3BHL000734P0003

ABB 3BHL000986P0006

ABB 3BHL001433P0001

ABB 3BHT300011R1

ABB 3BSE003816R1 SC520

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004172R1 PFTL101A-2KN

ABB 3BSE004172R1 PFTL101A 2KN

ABB 3BSE018135R1

ABB 3BSE019050R200 PFTL301E-0.2kN

ABB 3BSE030928R1 SM810K01

ABB 3BSE042235R2

ABB 3BSE042236R1 PP865

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE043660R1 CI867K01

ABB 3BSE056899R1 CI873K01

ABB 3BSE066490R1

ABB 3BSE076939R1 PM866AK01

ABB 3BSE091722R1 LD 810HSE EX

ABB 3BSE092689R1

ABB 3BSE092689R1 CI867AK01

ABB 3BSE092978R1 PP881

ABB 3BUS208797-001

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626