Description

RLX2-IHNF-W-E is a cutting-edge signal conditioner and isolator designed for seamless integration into various industrial automation systems. It works by filtering out electrical noise and interference from the input signal, ensuring that only clean and accurate data is transmitted to the control system. The isolation function of this module separates the input and output circuits, protecting sensitive equipment from electrical surges and grounding loops, which is crucial for maintaining the safety and stability of the system.

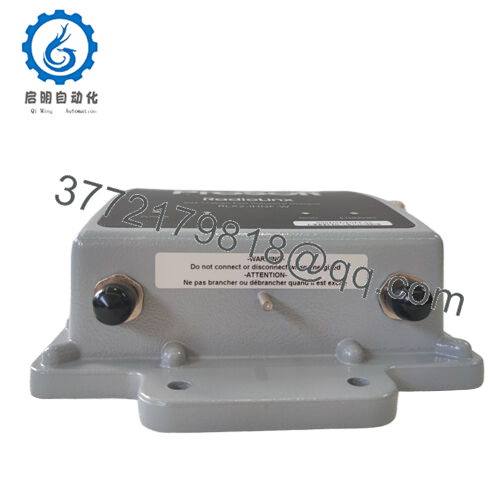

RLX2-IHNF-W-E

This module is designed to easily interface with various control platforms, backplane systems, and field devices. It supports multiple types of analog and digital signals, including common industry standards such as 4-20mA, 0-10V, and TTL/CMOS. RLX2-IHNF-W-E is also equipped with advanced diagnostic functions that can continuously monitor signal quality, power levels, and equipment health. By providing real-time status updates, it enables engineers to proactively address potential issues, reduce downtime, and optimize system performance. Whether as part of a new automation project or an upgrade to existing settings, RLX2-IHNF-W-E can enhance the overall reliability and efficiency of industrial automation systems.

RLX2-IHNF-W-E

Technical specifications:

Model RLX2-IHNF-W-E

Brand PROSOFT

Type: Sturdy signal conditioner and isolator

Input voltage 24 VDC ± 20%

Working temperature range -40 ° C to 80 ° C

Installation method: DIN rail installation with IP67 protective shell

Size 130mm x 70mm x 50mm

Weight 400g

Interface/bus simulation (4-20mA, 0-10V), digital (TTL/CMOS)

Certified CE, UL, RoHS, IP67

Typical power consumption 7W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

RLX2-IHNF-W-E

Main features and advantages:

Its sturdy IP67 protective casing gives it high dust, water, and physical impact resistance, ensuring reliable operation even in the harshest environments. This durability significantly reduces the frequency of equipment replacement and maintenance, thereby lowering long-term operating costs.

Engineers will appreciate the ease of integration of this module. Its standardized interface and plug and play design reduce installation time and complexity, and lower engineering costs. The built-in diagnostic tool simplifies the troubleshooting process, allowing technicians to quickly identify and resolve signal related issues, thereby shortening the average repair time. In addition, the excellent signal conditioning capability of RLX2-IHNF-W-E ensures the consistency and accuracy of data transmission, thereby improving the process control level of industrial automation systems, enhancing product quality, and increasing overall productivity.

RLX2-IHNF-W-E

Application areas:

In the mining industry, it can be used to regulate and isolate signals from sensors that monitor conveyor belt speed, ore levels, and equipment vibration. Its sturdy design enables it to withstand the dust and harsh conditions of the mining site, ensuring continuous and accurate data collection for efficient operation.

In outdoor manufacturing factories, there are daily challenges of exposure to the natural environment, and RLX2-IHNF-W-E can be used to maintain the integrity of signals from temperature sensors, humidity sensors, and pressure sensors. This enables precise process control regardless of weather conditions, ensuring consistent product quality.

Maritime applications have also benefited greatly from it. On ships and offshore platforms, it can condition signals from navigation systems, engine monitoring sensors, and safety equipment. IP67 protection ensures that the module can function properly even in the face of saltwater splashes, high humidity, and harsh weather, contributing to the safe and reliable operation of maritime vessels.

RLX2-IHNF-W-E

Related products:

RLX2-IHNF-A: It has basic signal conditioning functions and is suitable for less harsh environments.

RLX2-IHNF-W-E Plus: With additional input/output channels and advanced diagnostic capabilities, it is suitable for more complex settings.

[Brand Name] SCN-5000R: A robust modular signal conditioning system that can be customized and integrated with RLX2-IHNF-W-E, suitable for large-scale projects.

RLX2-IHNF-S-E: A variant optimized for high-speed signal processing in applications that require fast data transmission.

[Competitor Brand] SC-300R: Another robust signal conditioner with different interface options, providing an alternative solution for specific installation needs.

RLX2-IHNF-W-E Mini: Compact version with reduced size, suitable for space constrained installations.

RLX2-IHNF-W-E

Installation and maintenance:

Before installingRLX2-IHNF-W-E , it is essential to verify the compatibility of input and output signal types with the connected devices. Ensure that the power supply voltage in the automation system is within the range specified by the module. Although the module has an IP67 protective casing, it should still be installed in a location that minimizes exposure to extreme mechanical stress. In addition, check the integrity of the wiring connections to avoid any potential signal loss or interference issues.

For continuous maintenance, the casing should be regularly inspected for any signs of physical damage that may damage its IP67 protection. If the shell accumulates dust or debris in a dusty environment, its exterior should be cleaned. Regularly monitor the status indicator lights to track the operation status of the module. If there is a signal issue, please use the built-in diagnostic function to promptly identify and correct the problem. Conduct routine signal accuracy testing to ensure that the module continues to maintain optimal performance and maintain the reliability of industrial automation systems.

PROSOFT Other product models:

PROSOFT MV156E-MNETC

PROSOFT RLX2-IHNF-A

PROSOFT RLX2-IHNF-A

ProSoft PLX31-EIP-SIE

ProSoft MVI56-MBP

ProSoft MVI56-MBP

ProSoft 5205-DFNT-PDPS

PROSOFT 5205-DFNT-PDPS

PROSOFT 5205-DFNT-PDPS

PROSOFT 5105-MCM-PDPS

PROSOFT MVI56-101M

PROSOFT MVI94-MCM-MHI

PROSOFT MVI56-101M

PROSOFT PLX31-EIP-MBS4

PROSOFT PLX31-EIP-ASCII4

PROSOFT MVI56-BAS

PROSOFT RLX2-IHNF-W-E

PROSOFT MVI69L-MBTCP

PROSOFT MVI56EAFC

PROSOFT MVI56E-AFC

PROSOFT PLX51-PBM

PROSOFT TQ-PDPMV1

PROSOFT PLX32-EIP-SIE

PROSOFT PLX32-EIP-SIE

PROSOFT ILX56-PBM

PROSOFT MVI56E-GEC

PROSOFT PLX31-EIP-SIE

PROSOFT MVI46-MNET

PROSOFT PLX31-EIP-MBS4

PROSOFT PLX51-PBM

Prosoft A-CNR

PROSOFT PTQ-PDPMV1

ProSoft AN-X2-AB-DHRIO

ProSoft MVI56E-SIE

ProSoft ILX34-MBS485

PROSOFT RLX2-IHNF

PROSOFT RLX2-IHNF-A

Prosoft 5302-MBP-MCM4

Prosoft PLX32-MBTCP-SIE

Prosoft PLX32-MBTCP-SIE

PROSOFT PLX82-EIP-PNC

ProSoft PLX82-EIP-PNC

PROSOFT PLX32-EIP-MBTCP

Prosoft RLX2-IHNF-W-A

Prosoft LX32-EIP-MBTCP

PROSOFT PLX31-EIP-SIE

PROSOFT MVI56E-MNETC

ProSoft MVI56E-SIE

PROSOFT MVI56-MCM

PROSOFT MVI56-PDPS

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626