Description

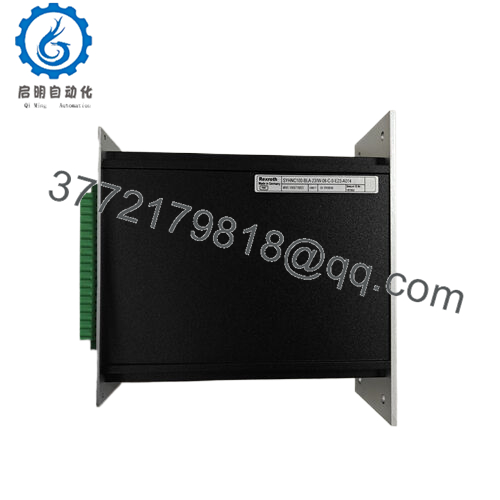

The REXROTH HNC100 SYHNC100-BLA-23W-08-C-0-E23-A014 is a digital axis controller specifically designed for high-precision closed-loop control of hydraulic and electric drives in industrial automation. It is commonly employed in applications such as machine tools, presses, plastics processing machines, transfer lines, and rail-bound vehicles, where precise position, velocity, and force control are critical. This controller meets the rigorous demands of harsh industrial environments, offering immunity to electrical interference, mechanical vibration resistance, and climate robustness. The versatility of the HNC100 allows it to manage complex motion profiles and synchronized multi-axis movements, making it valuable in control systems requiring tight integration of motion sequences and real-time process adaptation.

The REXROTH HNC100 SYHNC100-BLA-23W-08-C-0-E23-A014 serves as a programmable NC (Numerical Control) digital axis controller. It controls a single or dual hydraulic or electric axis by executing user-defined programs using NC language that includes subprograms, conditional jumps, and various motion commands. The device features a 16/32-bit processor with 1 MB Flash EPROM, 8 KB EEPROM, and 256 KB RAM memory, supporting robust user programming and data storage. It interfaces with several sensors and actuators via digital and analog inputs and outputs, providing fine control over the positioning and force applied by axis drives. Integration with fieldbus systems like Profibus DP, CANopen, and INTERBUS-S enhances communication within automated plants. The controller’s compact, rugged casing suits panel mounting in industrial cabinets, providing straightforward hardware installation.

Technically, the HNC100 SYHNC100-BLA-23W-08-C-0-E23-A014 features flexible input/output options, offering 8, 16, or 24 digital inputs and outputs capable of handling up to 50 mA per channel. It includes four differential analog voltage and current inputs for precise measurement and control signals, supporting ranges of ±10 V and 4-20 mA. Its dual support for incremental and SSI (Synchronous Serial Interface) transducers ensures accurate position feedback essential for closed-loop control. The operating voltage ranges between 18 and 36 V DC, with a nominal power consumption around 8 W, excluding external sensors. Its programming environment supports complex control logic, including sequence programming, curve definitions, and synchronized two-axis control. The controller’s design ensures stable operation in heavy-duty industrial conditions, preventing interference and maintaining high availability. These features make it exceptionally suitable for demanding motion control tasks requiring reliability and functional safety.

| Parameter | Value |

|---|---|

| Model | SYHNC100-BLA-23W-08-C-0-E23-A014 |

| Brand | Rexroth (Bosch Rexroth) |

| Type | Digital Axis Controller for Hydraulic/Electric Drives |

| Processor | 16/32-bit MC68376 |

| Memory | 1 MB Flash EPROM; 8 KB EEPROM; 256 KB RAM |

| Digital Inputs/Outputs | 8, 16, or 24 channels; up to 50 mA max per channel |

| Analog Inputs | 4 differential voltage (±10V), 4 current (4-20 mA) |

| Position Transducers | Incremental and SSI |

| Operating Voltage | 18 to 36 V DC |

| Power Consumption | Approx. 8 W (excluding sensors/actuators) |

| Interface Protocols | Profibus DP, CANopen, INTERBUS-S |

| Operating Temperature | 0 to 50 degrees Celsius |

| Mounting | Panel Mounted |

| Protection | Industrial enclosure |

- HNC100 SYHNC100-BLA-23W-08-C-0-E23-A014

Related products to the HNC100 SYHNC100-BLA-23W-08-C-0-E23-A014 include Rexroth’s VT-HNC100 series, offering similar functionality with varied I/O configurations and additional programming features. Complementary hydraulic valves, sensors, and proportional valves round out system capabilities for integrated motion and force control. The IndraDrive series servo drives integrate with the HNC100 for electric axis control. Fieldbus interface modules such as Profibus and CANopen adaptors allow flexible communication within complex automation networks.

Installation of the HNC100 controller requires mounting in a protected control cabinet area allowing adequate ventilation for heat dissipation. Proper grounding is critical to protect against electromagnetic interference which may affect sensitive analog signals and communication protocols. Cabling for analog, digital, and feedback signals should adhere to Rexroth’s specifications for shielding and separation to minimize noise. Regular inspections of connector integrity, firmware updates through PC interfaces, and scheduled performance diagnostics optimize device longevity and maintain system responsiveness throughout operational cycles.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626