Description

In the realm of industrial automation, where precise motion control directly impacts throughput and precision, the Bosch Rexroth DKC03.3-040-7-FW stands out as a targeted solution for engineers facing challenges in synchronizing high-torque servo operations. Picture a packaging line where inconsistent motor response leads to misalignment or jams, or a machine tool setup where torque fluctuations compromise cut quality—these are the everyday hurdles this drive controller overcomes by delivering stable, programmable power to AC servo motors. It addresses the core need for reliable velocity and position regulation in multi-axis systems, ensuring signals remain clean and commands execute without lag, even under variable loads.

This becomes particularly vital in process control environments like assembly lines or material handling, where downtime from erratic drives can escalate costs quickly. The Bosch Rexroth DKC03.3-040-7-FW integrates seamlessly to enhance system stability, filtering electrical noise and adapting to dynamic demands for smoother operation. For teams upgrading from legacy controllers, it minimizes integration friction while boosting I/O signal integrity, allowing focus on optimization rather than constant adjustments. In high-reliability scenarios, such as those demanding continuous uptime, this unit prevents cascading failures by maintaining consistent output, ultimately supporting scalable automation that aligns with tightening production schedules.

Engineers often turn to the Bosch Rexroth DKC03.3-040-7-FW when retrofitting older motion systems, as its firmware-driven logic handles complex positioning tasks without custom hardware overhauls. By prioritizing torque control and feedback loop precision, it reduces the engineering overhead associated with tuning for specific motor profiles, making it a go-to for environments where every millisecond of response time counts in industrial automation workflows.

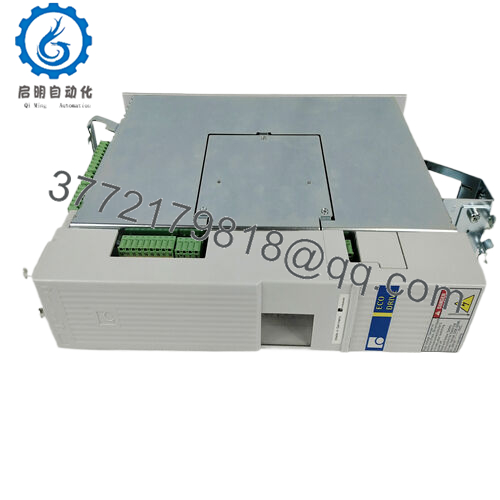

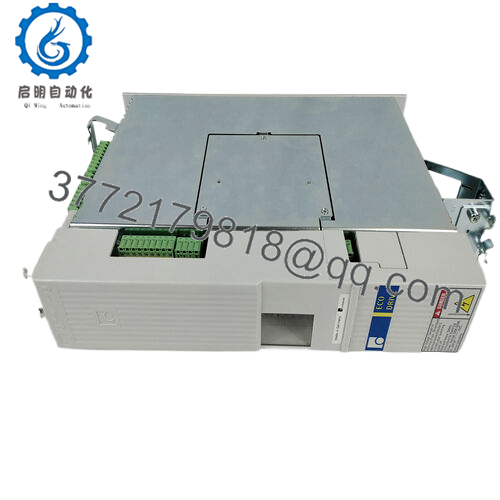

The Bosch Rexroth DKC03.3-040-7-FW functions as a compact AC servo drive controller in the EcoDrive series, positioned at the heart of the motion control layer within your automation architecture. It takes three-phase input power and converts it to controlled DC output for driving Indramat MKD servo motors, using advanced pulse-width modulation to regulate speed, torque, and position based on real-time feedback from encoders or resolvers. This setup allows it to slot into backplane or standalone configurations, communicating via PROFIBUS DP for cyclic data exchange with PLCs, HMIs, or upper-level controllers, ensuring coordinated multi-axis motion without bottlenecks.

In a typical system, it pairs with power supplies and regenerative modules to form a shared DC bus, distributing energy efficiently across drives for regenerative braking in dynamic applications. Built-in diagnostics monitor parameters like overcurrent or thermal status, flagging issues early to support hot-swapping in redundant setups. While it leverages standard protocols for plug-and-play connectivity, optional cards expand to RS232/485 or analog interfaces, fitting diverse I/O architectures. For instance, in a distributed control platform, the Bosch Rexroth DKC03.3-040-7-FW acts as the executor of motion commands, translating high-level process logic into precise motor actions while feeding back operational data for closed-loop optimization—keeping the entire stack responsive and fault-tolerant.

- DKC03.3-040-7-FW

| Specification | Details |

|---|---|

| Model Number | DKC03.3-040-7-FW |

| Brand | Bosch Rexroth |

| Type | AC Servo Drive Controller |

| Input Voltage | 200-480 V AC, 3-phase, 50-60 Hz |

| Operating Temp Range | 0°C to 45°C |

| Mounting Style | Panel Mount |

| Dimensions | 336 x 145 x 284 mm |

| Weight | 5.7 kg |

| Interface/Bus | PROFIBUS DP, RS232/485 |

| Compliance | CE, UL 508C, cULus |

| Supported Protocols | PROFIBUS DP, Modbus (optional) |

| Typical Power Draw | 40 A rated current |

Opting for the Bosch Rexroth DKC03.3-040-7-FW equips your setup with engineered resilience that sustains peak performance across extended runs, minimizing thermal drift and voltage sags that plague lesser drives in demanding cycles. This reliability shines in torque-heavy tasks, where it maintains output fidelity to prevent mechanical stress on connected motors, extending equipment lifespan and cutting unplanned service calls.

Its diagnostic depth further enhances maintenance efficiency, surfacing error codes and trend data that let your team address root causes proactively, rather than reacting to failures—slashing downtime by up to 30% in well-monitored systems. Integration ease reduces engineering overhead too; with modular firmware updates, adapting to evolving process needs involves simple parameter tweaks, not full reconfigurations, freeing resources for innovation.

In essence, this drive delivers consistent motion outcomes that bolster overall system throughput, ensuring your automation investment yields measurable gains in precision and operational flow without the hidden costs of frequent interventions.

Within printing machine environments, the Bosch Rexroth DKC03.3-040-7-FW drives high-speed web handling, where its fast response cycles ensure registration accuracy under continuous uptime pressures, preventing web breaks in 24/7 production.

For machine tool applications in metalworking, it powers spindle and axis controls, meeting needs for high reliability in harsh, vibration-laden conditions to sustain micron-level precision over long shifts.

In packaging automation, this controller orchestrates multi-axis filling and sealing operations, supporting rapid data cycles for synchronized motion that optimizes throughput while upholding critical system uptime in fast-paced facilities.

DKC03.3-100-7-FW – Higher current variant for applications requiring up to 100 A output in heavier load scenarios. DKC03.3-016-7-FW – Lower power option at 16 A for lighter-duty motion tasks with similar interface compatibility. DKC02.3-040-7-FW – SERCOS interface alternative for fiber-optic networked systems in high-speed synchronization. DKC04.3-040-7-FW – Interbus-focused model for legacy fieldbus integrations in older automation stacks. DKC05.3-040-7-FW – CANopen version enabling real-time control in distributed CAN-based architectures. DKC11.3-040-7-FW – Analog interface edition for simpler, non-networked setups with direct signal handling. R911279428 – Firmware upgrade kit for enhanced parameter tuning on existing DKC03.3 units.

Prior to installing the Bosch Rexroth DKC03.3-040-7-FW, confirm your power supply matches the 200-480 V AC three-phase spec and that enclosure ventilation accommodates the internal blower’s airflow requirements to avoid thermal throttling. Verify PROFIBUS cable quality and terminator settings for clean network communication, and cross-check motor compatibility—pairing it exclusively with MKD series ensures optimal feedback loop stability without adapter hassles. Firmware should be at the latest revision for full diagnostic access, downloadable from Rexroth’s portal.

Maintenance revolves around quarterly visual checks for dust on heatsinks and connectors, as accumulation can skew cooling efficiency in dusty shop floors. Use the RS232 port for routine parameter reads via DriveTop software, noting any fault histories to predict wear on capacitors or fuses. Annual load testing under simulated conditions validates current handling, and replacing the 20 A branch fuse only with exact equivalents prevents overcurrent risks. This disciplined routine keeps the drive humming reliably, with minimal disruption to your production rhythm.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626