Description

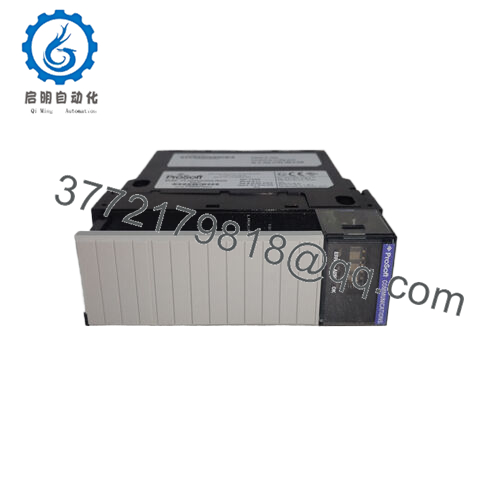

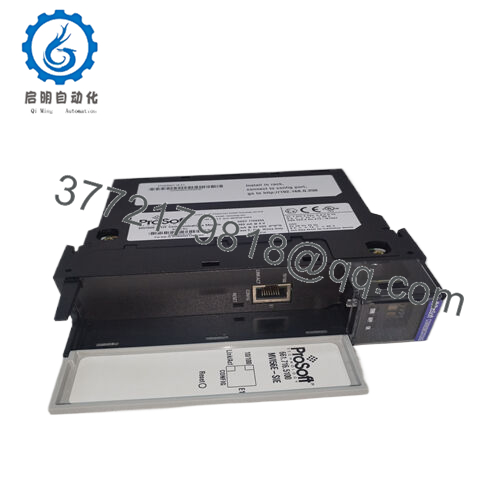

PROSOFT MVI56E-SIE acts as a vital translator within the automation stack, facilitating communication between Allen-Bradley ControlLogix backplane systems and Siemens S7 controllers. It supports the Siemens S7 protocol over Ethernet, allowing for seamless data transfer between these two major automation platforms. This module integrates effortlessly into the ControlLogix architecture, functioning as an I/O device that can be easily configured using the native programming environment. With built-in diagnostic features, it continuously monitors communication status, quickly alerting operators to any potential connectivity issues or data transmission errors. Its support for redundant Ethernet networks ensures uninterrupted operation, providing failover protection and enhancing overall system reliability. This makes it a crucial component for maintaining the integrity of industrial automation processes that rely on the cooperation of multiple control systems.

MVI56E-SIE

Technical specifications:

Model MVI56E-SIE

Brand PROSOFT

Type Ethernet Interface Module

Input Voltage 10 – 30 VDC

Operating Temp Range -40°C to 75°C

Mounting Style Installs in ControlLogix backplane

Weight Approximately 0.15 kg

Interface/Bus Ethernet, ControlLogix backplane

Compliance CE, UL, cUL

Supported Protocols Siemens S7 protocol over Ethernet

Typical Power Draw 3.5W

contact information

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

MVI56E-SIE

Main features and advantages:

this module can withstand harsh operating conditions, ensuring long-term reliability even in demanding environments. Its ability to seamlessly bridge the communication gap between different control platforms eliminates the need for complex, custom coding, thereby reducing engineering overhead and speeding up project timelines. The real-time diagnostic capabilities empower maintenance teams to proactively address issues, minimizing unplanned downtime and improving overall operational efficiency. By enabling smooth data flow between Allen-Bradley and Siemens systems, the MVI56E-SIE allows industrial facilities to leverage the strengths of both platforms, optimizing processes and driving productivity gains.

MVI56E-SIE

Application areas:

In the field of oil and gas, it is used to connect different control systems of refineries and offshore platforms, ensuring seamless data exchange to monitor and control complex processes. In these fields, the demand for continuous normal operation and reliable communication in harsh and explosive environments makes the robust design and redundant network support of this module particularly important. In the water and wastewater treatment industry, it supports communication between different control components in the treatment plant, thereby helping to accurately manage processes such as filtration, chemical dosing, and pumping. In addition, in automobile manufacturing plants, automation systems from different suppliers work together, and MVI56E-SIEensures smooth coordination between production lines, robotic arms, and quality control systems, thereby improving production accuracy and output.

MVI56E-SIE

Related products:

MVI56E-MCM – Provides multi-channel communication support for more complex network settings.

MVI56E PDPS – designed specifically for Profibus DP slave communication integration.

MVI56E MNET – Supports communication via Modbus TCP/IP protocol.

MVI56E-FCM – focuses on fiber optic communication to achieve long-distance data transmission.

MVI56E-PNP – Supports point-to-point communication to meet specific application requirements.

MVI56E-CM – Suitable for simpler communication tasks.

MVI56E-ADM – Supports advanced data mapping for custom communication between devices.

MVI56E-SIE

Installation and maintenance:

Before installing PROSOFT MVI56E-SIE , engineers must carefully check the compatibility of the ControlLogix backplane version with the module. It is also crucial to ensure that the power supply inside the backplane meets the requirements of the module. In addition, it is necessary to verify whether the network configuration (including IP addressing and subnet mask) is consistent with the Siemens S7 controller to avoid communication errors. For continuous maintenance, regularly checking the status LED of the module can quickly understand its operating condition.

Regularly checking the backplane connections can prevent problems caused by loose or corroded contacts. Following PROSOFT’s recommendations for routine firmware updates can help keep modules up-to-date with the latest features, security patches, and performance improvements, ensuring they continue to operate at their best in industrial automation environments.

PROSOFT related products:

PROSOFT MVI56E-MCM

PROSOFT MVI56E-MCM

ProSoft PLX35-NB2

Prosoft MVI56-ADMNET

Prosoft MVI56E-LDM

ProSoft MVI56-ADMNET

prosoft RLX2-IHNF-W-E

ProSoft PLX32-EIP-PND

PROSOFT MVI56E-MCMR

PROSOFT 5302-MBP-MCM4

ProSoft PLX32-EIP-PND

Prosoft RLX2-IFH24E

ProSoft XV-363-10-C02-A00-1B

ProSoft PLX32-MBTCP-104

PROSOFT PLX82-MNET-61850

PROSOFT MV156E-MNETC

PROSOFT RLX2-IHNF-A

PROSOFT RLX2-IHNF-A

ProSoft PLX31-EIP-SIE

ProSoft MVI56-MBP

ProSoft MVI56-MBP

ProSoft 5205-DFNT-PDPS

PROSOFT 5205-DFNT-PDPS

PROSOFT 5205-DFNT-PDPS

PROSOFT 5105-MCM-PDPS

PROSOFT MVI56-101M

PROSOFT MVI94-MCM-MHI

PROSOFT MVI56-101M

PROSOFT PLX31-EIP-MBS4

PROSOFT PLX31-EIP-ASCII4

PROSOFT MVI56-BAS

PROSOFT RLX2-IHNF-W-E

PROSOFT MVI69L-MBTCP

PROSOFT MVI56EAFC

PROSOFT MVI56E-AFC

PROSOFT PLX51-PBM

PROSOFT TQ-PDPMV1

PROSOFT PLX32-EIP-SIE

PROSOFT PLX32-EIP-SIE

PROSOFT ILX56-PBM

PROSOFT MVI56E-GEC

PROSOFT PLX31-EIP-SIE

PROSOFT MVI46-MNET

PROSOFT PLX31-EIP-MBS4

PROSOFT PLX51-PBM

Prosoft A-CNR

PROSOFT PTQ-PDPMV1

ProSoft AN-X2-AB-DHRIO

ProSoft MVI56E-SIE

ProSoft ILX34-MBS485

PROSOFT RLX2-IHNF

PROSOFT RLX2-IHNF-A

Prosoft 5302-MBP-MCM4

Prosoft PLX32-MBTCP-SIE

Prosoft PLX32-MBTCP-SIE

PROSOFT PLX82-EIP-PNC

ProSoft PLX82-EIP-PNC

PROSOFT PLX32-EIP-MBTCP

Prosoft RLX2-IHNF-W-A

Prosoft LX32-EIP-MBTCP

PROSOFT PLX31-EIP-SIE

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626