Description

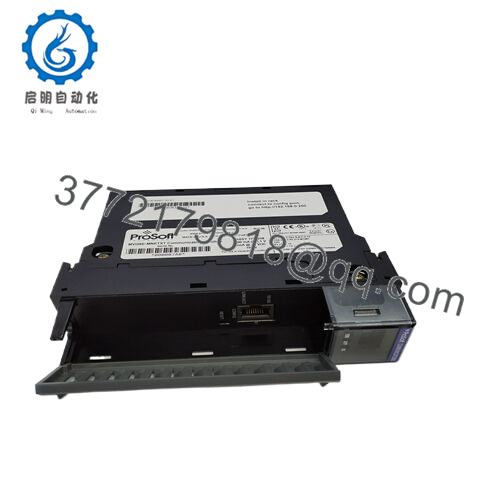

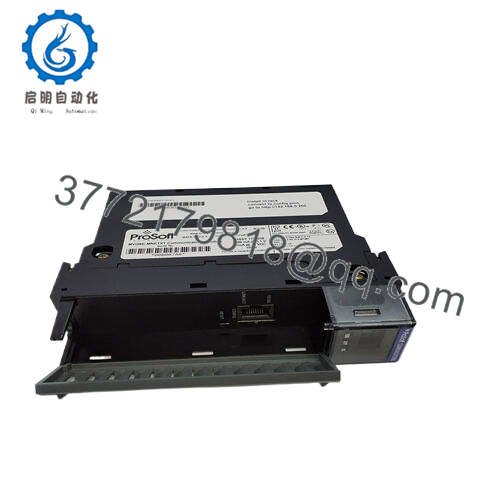

The Prosoft MVI56E-MNETXT is an enhanced Modbus TCP/IP Client/Server communication module designed for Rockwell Automation’s ControlLogix and CompactLogix platforms. It enables seamless integration of Modbus TCP/IP networks with the Logix control system, making it an ideal choice for industrial automation scenarios requiring high reliability, flexible connectivity, and advanced network diagnostics.

Industries such as manufacturing, energy, water treatment, and building automation leverage the MVI56E-MNETXT to bridge diverse Ethernet-based devices and protocols, streamlining data exchange for improved monitoring and control. This module excels in environments demanding rugged performance under extended temperature ranges and harsh conditions, including caustic or corrosive atmospheres. Its CIPconnect-enabled architecture allows for transparent data sharing between Modbus devices and Rockwell Automation processors, facilitating complex system integration without the need for costly protocol converters.

The MVI56E-MNETXT supports full Modbus TCP Client and Server functionality, along with rich diagnostic features accessible via built-in web pages and ProSoft Configuration Builder (PCB) software. It is backward compatible with earlier MVI56-MNET versions but adds extended temperature (up to 70°C operating), enhanced security, and conformal coating for extreme environments. The module’s single-slot design fits easily into the 1756 ControlLogix backplane, requiring approximately 800 mA at 5 VDC and 3 mA at 24 VDC power.

Engineers appreciate the module’s 4-character scrolling alphanumeric LED display which provides clear status, IP address, configuration, and error information in plain English, eliminating cryptic codes and simplifying troubleshooting. Integrated Ethernet port auto-negotiates between 10/100 Mbps with link and activity LEDs. Shipment includes a 5-foot Ethernet straight-through cable, facilitating convenient installation.

- MVI56E-MNETXT

- MVI56E-MNETXT

Designed for rugged industrial use, the MVI56E-MNETXT operates reliably from -25°C to 70°C, tolerates 30 g shock and 5 g vibration per IEC test methods, and withstands 5–95% humidity without condensation. This reliability ensures minimal downtime and simplified lifecycle management in critical control applications.

| Parameter | Value |

|---|---|

| Model | MVI56E-MNETXT |

| Brand | Prosoft Technology (Rockwell Automation) |

| Product Type | Modbus TCP/IP Client/Server Communication Module |

| Control System Compatibility | ControlLogix, CompactLogix |

| Network Interface | 10/100 Mbps Ethernet, RJ45 connector |

| Backplane Current Load | 800 mA @ 5 VDC, 3 mA @ 24 VDC |

| Operating Temperature | -25°C to 70°C |

| Storage Temperature | -40°C to 85°C |

| Humidity | 5% to 95% RH, non-condensing |

| Shock Resistance | 30 g operational |

| Vibration Resistance | 5 g from 10 Hz to 150 Hz |

| Diagnostic Display | 4-character scrolling alphanumeric LED |

| Software Support | ProSoft Configuration Builder (PCB), CIPconnect |

| Communication Protocols | Modbus TCP Client/Server |

Related Modules or Compatible Units

MVI56-PDPMV1 – PROFIBUS DP communication module for ControlLogix platforms.

1756-EN2T – Ethernet/IP communication adapter module for ControlLogix systems.

1788-EN2PAR – Ethernet/IP to PROFIBUS PA linking device.

MVI69-MNET – Modbus RTU/ASCII Master/Slave communication module.

1794-AENTR – FLEX I/O EtherNet/IP adapter supporting diverse I/O integration.

Installation of the MVI56E-MNETXT requires a free single slot in a ControlLogix or CompactLogix rack with access to a 5 V and 24 V power supply according to manufacturer specifications. Use shielded Category 5e or better Ethernet cables and ensure proper grounding to mitigate electromagnetic interference common in industrial environments. The provided Ethernet cable facilitates initial network connection and configuration.

Regular maintenance includes reviewing diagnostic LEDs and the LED display for status indications, verifying Ethernet link integrity, and updating firmware via ProSoft tools. Periodic validation of network performance and configuration backups improve system reliability and facilitate efficient troubleshooting. Following Rockwell Automation’s installation and wiring guidelines ensures sustained performance and compliance with industrial standards.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626