Description

PQMII-T20-C is a three-phase power quality monitoring instrument designed to seamlessly integrate with industrial control systems, programmable logic controllers (PLCs), and data acquisition and monitoring control system (SCADA) platforms. Its main function is to continuously measure and analyze over 100 electrical parameters, including three-phase voltage, current, frequency, total harmonic distortion (THD), and power factor. This module is equipped with advanced signal processing capabilities, which collect raw data through current transformers (CT) and voltage transformers (VT), and then process it into actionable insights through its intuitive interface or industrial protocols such as Modbus TCP or Profibus.

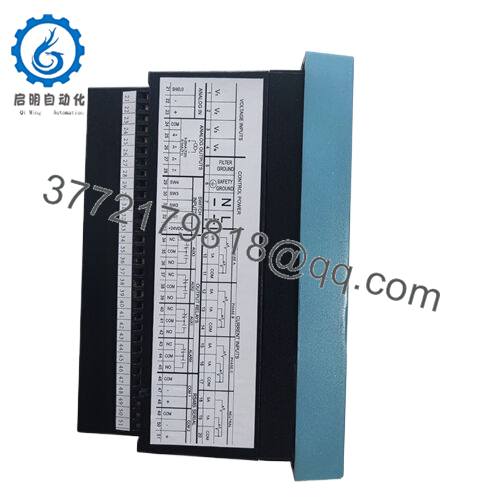

PQMII-T20-C

As a first-line diagnostic tool, this monitor is usually installed at the point of common coupling (PCC) or critical subsystem. It supports real-time alarm triggering for out of range parameters (such as voltage exceeding ± 10% tolerance) and sends instant alerts through email, SMS, or SCADA notifications.PQMII-T20-C can also store historical trend data for up to [X] days, facilitating root cause analysis of recurring issues. Although it does not directly control the equipment, its predictive analysis function allows the team to prioritize maintenance work, such as replacing the capacitor bank before it ages and causes a power outage.

PQMII-T20-C

Technical specifications:

Model PQMII-T20-C

Brand GE

Type Three phase power quality monitoring instrument

Input voltage 85-690 VAC (universal three-phase)

Operating temperature range -40 ° C to+85 ° C (industrial grade durability)

Installation method: DIN rail or panel installation (IP65 protection level enclosure, suitable for harsh environments)

Interface/Bus Ethernet (Modbus TCP), RS-485 (Modbus RTU), Profibus DP, CANopen

Compliance with IEC 61000-4-3, IEEE 519, CE, UL, CSA

Supported protocols Modbus, Profibus, DNP3, IEC 61850

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

PQMII-T20-C

Main features and advantages:

Choosing PQMII-T20-C means investing in a solution aimed at improving operational resilience and cost-effectiveness. Its high-precision measurement (voltage/current accuracy ± 0.2%) ensures accurate energy auditing and helps identify wasteful behaviors such as overload or reactive power loss. For example, a food processing plant using this monitor may find that its refrigeration system has load imbalance issues, and rebalancing the load can reduce energy costs by 12%.

The real-time alarm system of this module can reduce unplanned downtime by up to 50% by alerting the team to issues such as harmonic levels exceeding IEEE 519 limits or sudden frequency deviations. This proactive approach, combined with trend analysis, enables predictive maintenance, such as scheduling transformer repairs during planned downtime rather than repairing after a fault occurs. In addition, its plug and play integration with existing SCADA systems can shorten deployment time by 30%, while its robust structure (IP65 protection level) ensures reliability in dusty, humid, or high vibration environments.

PQMII-T20-C

Application areas:

PQMII-T20-Cperforms well in industries where power quality directly affects productivity and compliance:

Manufacturing and automotive industries: deployed in factory workshops to monitor the power supply lines of CNC machine tools, robotic arms, and conveyor systems, ensuring stable operation and preventing defects caused by voltage fluctuations. In automobile factories, it may detect harmonic distortion generated by welding equipment, prompting the installation of filters to protect sensitive control systems.

Energy and Renewable Energy: Used for solar power plants, wind turbines, and microgrids, analyzing the quality of grid interconnection to ensure compliance with the IEEE 1547 Distributed Energy Resources (DER) standard. It can also optimize power factor correction in hybrid systems and increase energy production.

Medical and Pharmaceutical: Integrated into critical power systems in hospitals and cleanrooms, used to monitor uninterruptible power supply (UPS) outputs and emergency generators to prevent MRI equipment data loss or abnormal storage facility temperatures. It complies with the IEC 61000-4-3 standard, ensuring minimal electromagnetic interference (EMI) to medical equipment.

PQMII-T20-C

Related products:

PQMII-T40-C: Equipped with 16 inputs, suitable for large industrial complexes.

PQMII-T20-CH: Enhanced Harmonic Analysis Variant (up to 100 orders), suitable for semiconductor manufacturing plants.

PQMII-T10-C: Suitable for small and medium-sized enterprises (SMEs) or retail environments.

PQMII-T20-CR: Redundant power version, equipped with dual inputs, suitable for data centers and telecommunications hubs.

PQMII-T20-CE: Explosion proof variant, suitable for hazardous areas such as refineries.

PQMII-T20-CW: Wireless enabled model, suitable for remote sites, transmitting data via LTE or Wi Fi.

PQMII-T20-C

Installation and maintenance:

Before installation, please verify the compatibility of CT/VT with the input range of the monitor (e.g. 1A or 5A CT) and ensure proper grounding to reduce electromagnetic interference. Configure alarm thresholds according to industry standards (e.g. THD<5% for commercial buildings) and establish data recording intervals (e.g. 1-minute snapshot for load analysis). For multi monitor networks, please use VLAN to isolate power quality data from other traffic to ensure low latency alarms.

Routine maintenance includes quarterly checks for CT connections for oxidation or loose terminals, as well as annual firmware updates to access new features such as advanced harmonic trend analysis. Use the built-in event log of the monitor to view interference records (such as voltage surges during the start-up of large motors) and optimize control strategies, such as implementing soft starters. In corrosive environments, please check the enclosure seals annually to maintain the integrity of the IP65 protection level.

Other GE brand product models:

GE 176449-05

GE C200/10/1/1/1/00

GE DS200CDBAG1A

GE 151X1233DB02SA02

GE IS210SAMBH1A

GE IS420UCSBH4A

GE 151X1235DB15SA01

GE DS303A3A01GXA003XF

GE DS303A3C01GXA003XP

GE IS215AEPAH1A

GE SR745-W2-P1-G1-HI-A-L-R

GE SR489-P1-HI-A20-E

GE SR745-W2-P1-G1-HI-A-L-R-E

GE SR489-P5-LO-A20-E

GE PWB68A993125

GE IS220PPROH1A

GE IS420UCSBH4A

GE IS420UCSBH1A

GE SDCS-PIN-48-COAT

GE SDCS-CON-H01

GE DS200ADMAH1A

GE DS200VPBLG2A

GE DS200DDTBG2A

GE IS415UCVHH1A

GE DS200SIOBH1ABA

GE IC695CPU315

GE SR469-CASE

GE IC754VSI06STD-KH

GE IS2020RKPSG2A

GE IS400AEBMH1AJD

GE DS200TCQCG1AJD

GE IS2020RKPSG2A

GE IC695CPU315

GE IS200EPCTG1A

GE IS200EDCFG1A

GE IS200EXAMG1A

GE IS200ERBPG1A

GE 345-E-P5-G5-H-E-S-N-N-3E-D-N

GE 1VCF750132802

GE MFAC34

GE 469-P5-HI-A20-E-H

GE 350-E-P1-G1-H-E-S-C-P-SN-D-N

GE 5266222-2 – GSCB GOC6.6

GE IS400AEBMH1AJD

GE DS200TCQCG1AJD

GE 239-RTD-AN

GE 239-RTD-AN

GE 239-RTD-AN

GE 269PLUS-100P-120VAC

GE IS420UCSBH1A

GE Physical 239 239-RTD-AN

GE VMIVME2540-300

GE 8507-BI-DP 8507-BI-DP-01

GE VMIVME2540

GE SLN042 IC086SLN042-A

GE SLN080 IC086SLN080-A

GE VMIACC-5595-208 350-805595-208N

GE SBC486DX66

GE F650 F650BFBF2G0HIE

GE VMIACC-5595-208

GE IS215WEPAH2B

GE IS210AEAAH2B

GE 239

GE 369 panel

GE IS210AEBIH3B

GE IC660EPM100J

GE VPROH2B IS215VPROH2BC

GE DS2020PDMAG6

GE IS220UCSAH1A

GE DS200TCQCG1AJD

GE IS200ECTBG1ADE

GE IS200EXHSG3REC

GE IS220PPDAH1A

GE 845-EP5M5G5HNNAANGAPBCSENWB

GE 336A5199AMP1

GE F35-C-U03-HUH-F8L-H67-M6T-PXX-UXX-WXX

GE C60-C-U03-HUH-F8L-H6U-M6D-P6D-U6T-WXX

GE HE700GEN200

GE IC697BEM763

GE 339-E-P1-G1-H-E-S-N-P-1E-D-N

GE DS3800NB1B

GE DS3800HFPB1F1E

GE IC695CPE330

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626