Description

PQMII-T20-C-A is an advanced three-phase power quality monitoring instrument designed to seamlessly integrate with the industrial control system ecosystem. Its function is achieved through continuous measurement and analysis of a comprehensive set of electrical parameters. By utilizing advanced sensors and signal processing algorithms, it is able to capture data such as voltage, current, frequency, power factor, and harmonic distortion (up to high order, such as 50th order) in three phases.

PQMII-T20-C-A

The monitor obtains raw electrical data through current transformers (CT) and voltage transformers (VT). After data collection, it is processed internally and available for further analysis. In industrial environments, it can easily integrate with programmable logic controllers (PLCs), monitoring and data acquisition (SCADA) systems, or other power management platforms. Communicate seamlessly with the central control station through popular industrial protocols such as Modbus TCP/RTU.

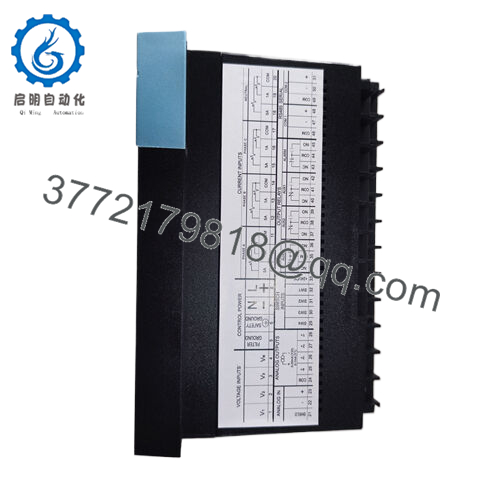

This module has multiple configurable outputs, including relay outputs, which can be set to trigger alarms or initiate corrective actions when power parameters deviate from preset thresholds. For example, if the voltage drops below a certain level or harmonic distortion exceeds acceptable limits, the relay can be programmed to send an alarm to the maintenance team and even activate the backup power system. It also has analog outputs, such as 4-20 mA signals, which can be used to interface with other analog based control devices or for further data recording.

PQMII-T20-C-A

Technical specifications:

Model numberPQMII-T20-C-A

Brand GE

Three phase power quality monitoring device with control function

Input voltage 70-265 VAC (50/60 Hz), wide range compatibility

Operating temperature range -20 ° C to+60 ° C, suitable for typical industrial environments

Installation method: DIN rail or panel installation, easy to install in the control cabinet

Interface/bus RS-232, RS-485, Ethernet (supporting Modbus), achieve diversified connectivity

Compliance with relevant industry standards, such as IEEE 519 Power Quality Standard

Supported protocols Modbus, DNP 3.0 (for enhanced communication in energy related systems)

Analog input 1 x 4-20 mA, for integration with external sensors

Relay output 4 x programmable relays for controlling actions and alarms

Waveform capture can capture and analyze voltage and current waveforms

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

PQMII-T20-C-A

Main features and advantages:

Its high-precision measurement (voltage and current accuracy of ± 0.5%) can achieve accurate energy auditing. By accurately tracking electricity consumption, the industry can identify inefficient areas and implement targeted energy-saving measures. For example, a large manufacturing plant may find that certain production lines consume excessive reactive power. With the insights provided by PQMII-T20-C-A, they can install power factor correction devices that may reduce energy costs by up to 15%.

The real-time alert system is a significant change in reducing unplanned downtime. In data centers, a sudden voltage spike may damage servers and interrupt services.PQMII-T20-C-Acan detect such anomalies within milliseconds and immediately trigger alerts through email, SMS, or SCADA notifications. This enables IT teams to take swift action, such as switching to backup power sources or adjusting power distribution systems, thereby reducing the risk of costly power outages.

This monitor can store historical data for a long time, which is very valuable for predictive maintenance. By analyzing the trend of power quality over a period of time, the maintenance team can predict equipment failures. For example, if the harmonic distortion level of an electric motor gradually increases, it may be a sign of impending mechanical or electrical problemsPQMII-T20-C-Acan achieve proactive replacement or repair, saving time and money in the long run.

PQMII-T20-C-A

Application areas:

Manufacturing industry: In automotive manufacturing factories, PQMII-T20-C-Acan be deployed to monitor the power supply of automated assembly lines, robot welding stations, and paint spraying robots. Accurate power quality monitoring ensures that high-precision operations are not interrupted by power fluctuations. For example, it can detect and correct voltage imbalances that may cause uneven welding of car bodies, improve product quality, and reduce scrap rates.

Energy industry: In power generation facilities, whether it is traditional power plants or renewable energy sites (such as wind farms or solar power plants), PQMII-T20-C-A helps maintain grid stability. It monitors the power output of the generator to ensure that the voltage, frequency, and harmonic levels are within an acceptable range for grid interconnection. In wind farms, it can detect power fluctuations caused by gusts and trigger control actions to regulate power output, ensuring smooth integration with the grid.

Healthcare facilities: Hospitals heavily rely on uninterrupted power supply to support life support systems, diagnostic equipment, and IT infrastructure. PQMII-T20-C-A can be used to monitor the power quality of critical areas such as intensive care units (ICUs) and operating rooms. By detecting any electrical abnormalities, it can prevent interference with sensitive medical equipment and ensure patient safety.

PQMII-T20-C-A

Related products:

PQMII-T30-C-A: Provides higher resolution measurements and additional channels, suitable for more complex industrial power systems. Suitable for large-scale manufacturing complexes with multiple power distribution networks.

PQMII-T20-C-B: slightly reduced functionality, suitable for small and medium-sized enterprises (SMEs) that still require basic power quality monitoring.

PQMII-T20-C-AH: capable of analyzing higher-order harmonics (such as 100th order). Recommended for industries with high non-linear loads, such as semiconductor manufacturing.

PQMII-T20-C-AR: Redundant power variant designed for critical mission applications that require continuous operation, such as data centers and emergency response facilities.

PQMII-T20-C-AW: Suitable for remote or difficult to wire industrial sites. It can transmit power quality data through Wi Fi or cellular networks, providing installation flexibility.

Installation and maintenance:

Before installation, it is necessary to verify whether the input voltage range of PQMII-T20-C-A matches the power supply in the industrial environment. Ensure that the size and compatibility of the current and voltage transformers connected to the monitor are correct. The equipment should be calibrated according to the manufacturer’s guidelines to ensure accurate measurements. When integrating with existing control systems, check communication settings such as baud rate and protocol configuration to ensure seamless data transmission.

Daily maintenance includes regular visual inspections of equipment to check for any signs of physical damage or overheating. Check whether the connections of current transformers, voltage transformers, and communication cables are loose or corroded. Regularly update firmware to access the latest features, improve measurement accuracy, and enhance security. Use the built-in diagnostic tool for self inspection and check for any abnormal readings. In dusty or humid environments, consider installing additional protective enclosures or ventilation systems to maintain optimal working conditions.

Other GE brand product models:

GE 176449-05

GE C200/10/1/1/1/00

GE DS200CDBAG1A

GE 151X1233DB02SA02

GE IS210SAMBH1A

GE IS420UCSBH4A

GE 151X1235DB15SA01

GE DS303A3A01GXA003XF

GE DS303A3C01GXA003XP

GE IS215AEPAH1A

GE SR745-W2-P1-G1-HI-A-L-R

GE SR489-P1-HI-A20-E

GE SR745-W2-P1-G1-HI-A-L-R-E

GE SR489-P5-LO-A20-E

GE PWB68A993125

GE IS220PPROH1A

GE IS420UCSBH4A

GE IS420UCSBH1A

GE SDCS-PIN-48-COAT

GE SDCS-CON-H01

GE DS200ADMAH1A

GE DS200VPBLG2A

GE DS200DDTBG2A

GE IS415UCVHH1A

GE DS200SIOBH1ABA

GE IC695CPU315

GE SR469-CASE

GE IC754VSI06STD-KH

GE IS2020RKPSG2A

GE IS400AEBMH1AJD

GE DS200TCQCG1AJD

GE IS2020RKPSG2A

GE IC695CPU315

GE IS200EPCTG1A

GE IS200EDCFG1A

GE IS200EXAMG1A

GE IS200ERBPG1A

GE 345-E-P5-G5-H-E-S-N-N-3E-D-N

GE 1VCF750132802

GE MFAC34

GE 469-P5-HI-A20-E-H

GE 350-E-P1-G1-H-E-S-C-P-SN-D-N

GE 5266222-2 – GSCB GOC6.6

GE IS400AEBMH1AJD

GE DS200TCQCG1AJD

GE 239-RTD-AN

GE 239-RTD-AN

GE 239-RTD-AN

GE 269PLUS-100P-120VAC

GE IS420UCSBH1A

GE Physical 239 239-RTD-AN

GE VMIVME2540-300

GE 8507-BI-DP 8507-BI-DP-01

GE VMIVME2540

GE SLN042 IC086SLN042-A

GE SLN080 IC086SLN080-A

GE VMIACC-5595-208 350-805595-208N

GE SBC486DX66

GE F650 F650BFBF2G0HIE

GE VMIACC-5595-208

GE IS215WEPAH2B

GE IS210AEAAH2B

GE 239

GE 369 panel

GE IS210AEBIH3B

GE IC660EPM100J

GE VPROH2B IS215VPROH2BC

GE DS2020PDMAG6

GE IS220UCSAH1A

GE DS200TCQCG1AJD

GE IS200ECTBG1ADE

GE IS200EXHSG3REC

GE IS220PPDAH1A

GE 845-EP5M5G5HNNAANGAPBCSENWB

GE 336A5199AMP1

GE F35-C-U03-HUH-F8L-H67-M6T-PXX-UXX-WXX

GE C60-C-U03-HUH-F8L-H6U-M6D-P6D-U6T-WXX

GE HE700GEN200

GE IC697BEM763

GE 339-E-P1-G1-H-E-S-N-P-1E-D-N

GE DS3800NB1B

GE DS3800HFPB1F1E

GE IC695CPE330

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626