Description

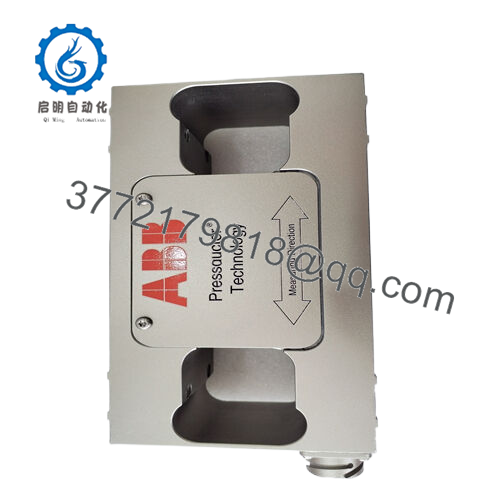

PFTL1101A 1.0KN Product Description:

PFTL1101A 1.0KN is a cutting-edge force sensing module that utilizes the principle of strain gauge technology. When mechanical force is applied, the strain gauges inside the module will deform, causing a change in resistance. Then, this small change will be amplified, conditioned, and converted into a precise electrical signal, which represents the magnitude of the applied force. This module supports industry standard communication protocols such as Profibus and Modbus RTU, making it seamlessly integrated into a wide range of automation systems. It is cleverly installed in the sensor layer of the automation stack, acting as an “eye” and “ear”, feeding real-time force data back to programmable logic controllers (PLCs), monitoring and data acquisition (SCADA) systems, and other higher-level control units. The built-in diagnostic function continuously monitors the performance of the module and the integrity of the measured signals. If any abnormal situation is detected, such as signal drift caused by temperature changes or electrical noise interference, it will immediately sound an alarm, allowing engineers to take proactive measures to prevent potential system failures.

PFTL1101A 1.0KN

Technical specifications:

Model PFTL1101A 1.0KN

Type of force sensing module

Rated load 1.0KN

Input voltage 24 VDC

Working temperature range -20 ° C to 60 ° C

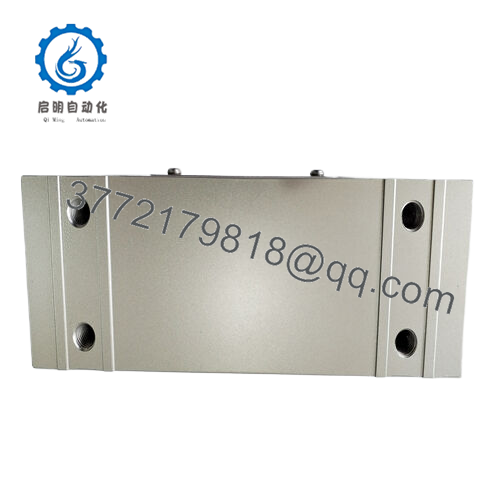

Installation method: flange installation

Dimensions 80mm x 60mm x 50mm

Weight 0.3 kg

Interface/Bus Profibus, Modbus RTU

Compliance certification CE, RoHS

Supports protocols Profibus DP and Modbus RTU

Typical power consumption 5 W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

PFTL1101A 1.0KN

Main features and advantages:

Its high-precision force measurement capability ensures that every manufacturing process can be executed accurately. For example, in a furniture manufacturing factory, when installing table legs onto the tabletop, the appropriate force required to tighten the connection can be precisely controlled to avoid damaging the wood due to excessive tightening or causing instability of the table due to insufficient tightening. This not only improves product quality, but also reduces material waste as fewer components are discarded due to improper assembly. The excellent long-term stability of this module means that the calibration interval can be extended, thereby saving a lot of maintenance time and resources. The reliable diagnostic function serves as a security guarantee, enabling early detection of potential issues and achieving predictive maintenance. This proactive approach minimizes unplanned downtime to the greatest extent possible, whereas in the industrial sector, every minute of production downtime means a loss of revenue. In addition, its compatibility with multiple industrial protocols simplifies system upgrades and extensions, enabling enterprises to adapt to constantly changing automation needs without causing significant disruptions.

PFTL1101A 1.0KN

Application areas:

PFTL1101A 1.0KN is a multifunctional solution with wide applications in various industries. In the field of electronic manufacturing, it is used to monitor the forces applied during the precise process of chip bonding. Ensuring the application of appropriate force is crucial to prevent damage to small and fragile components, thereby improving production yield. In the food and beverage industry, it plays a crucial role on the packaging line. During the bottle cap packaging process, this module monitors the torque force to ensure that the bottle cap is securely tightened without causing deformation or leakage, thereby maintaining the integrity and safety of the product. Another important application is in the aerospace field, where it is used to measure the forces applied during the assembly process of aircraft components. Accurate force measurement is crucial for ensuring the structural integrity of an aircraft, as any deviation could lead to catastrophic consequences.

PFTL1101A 1.0KN

Related products:

PFTL102A 2.0KN: Provides higher load-bearing capacity and is suitable for applications that require measuring larger forces, such as heavy material handling in construction equipment manufacturing.

PFTL100A 0.5KN: For applications with lighter loads, such as the assembly of small consumer electronics products, which involve relatively smaller forces, this product is a more cost-effective choice.

PFTL101B 1.0KN: This variant has enhanced environmental protection capabilities and can withstand harsh conditions, including high humidity, extreme temperatures, and dusty environments, making it ideal for outdoor or mining related applications.

PFTL101A-H 1.0KN: With higher accuracy and faster response time, it meets the needs of applications that require ultra precision and real-time force measurement, such as high-speed precision machining.

PFTL103A 1.5KN: Equipped with additional communication interfaces, it provides greater flexibility for integration into complex automation systems with multiple control units and diverse communication requirements.

PFTL101A-S 1.0KN: A compact version designed for installations with limited space, perfect for use in compact manufacturing units or small production lines, where every inch of space is precious.

Installation and maintenance:

Before installing PFTL1101A 1.0KN , the installation area must be carefully prepared. The surface should be smooth, without any burrs or unevenness, and properly cleaned to ensure a firm and accurate installation. Carefully check if the power supply voltage is accurately 24 VDC, as any deviation may affect the performance of the module or even cause damage. When integrating with existing control systems, carefully verify the communication protocol settings to ensure smooth data exchange. It is strongly recommended to use calibrated force standards for initial calibration to establish a reliable measurement benchmark.

Regular visual inspections of modules are crucial for daily maintenance. Check for any signs of physical damage, such as cracks in the casing or corrosion of the connectors. Closely monitor the diagnostic information provided by the module, and promptly handle any warnings or errors. Regular recalibration according to the manufacturer’s guidelines is necessary to maintain the accuracy of the module throughout its lifespan. In addition, it is necessary to protect communication cables from any pulling or damage to ensure the continuity and reliability of data transmission.

Other product models of ABB brand:

ABB unitrol1000-7 3BHE016011R0006

ABB UNITROL1010 3BHE035301R1002

ABB UNITROL1010-0410

ABB UNITROL1020 3BHE030579R0006

ABB UNITROL1020 UNS0119A-Z,V1 3BHE030579R000

ABB XUD194 XUD194A 3BHC018137R0001

ABB XV5628A

ABB Y129740-002

ABB YPI105C

ABB YPK112A 3ASD573001A13

ABB YPO104

ABB YPP-105F(YT204001)

ABB YPP110

ABB YPQ110A

ABB YPQ110A 3ASD573001A5

ABB С-093H

ABB PCD231

ABB HIEE300661R0001 UPC090AE01

ABB FMT200-ECO2

ABB 3BHB040253R0001

ABB SC520M 3BSE016237R1

ABB REC670 1MRK004814-AG

ABB TGM5 P14436-1072510

ABB GOP2000

ABB GOP2010

ABB 3BHE030579R0003

ABB 1SVR040000R1700

ABB DCF506-0140-51-0000000

ABB PCD530

ABB 1TGE120016R0104

ABB 1MRK000614-AB

ABB 5SHY35L4510

ABB PYT0450W071A

ABB 3BSE003832R1 SC510

ABB LM200

ABB SPAJ110C

ABB 1KHL178016R0001F

ABB 1KHL160038R0104D

ABB UP10C01000

ABB LD800HSE 3BDH000320R02

ABB 5SHY35L4520 5SXE10-0181

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626