Description

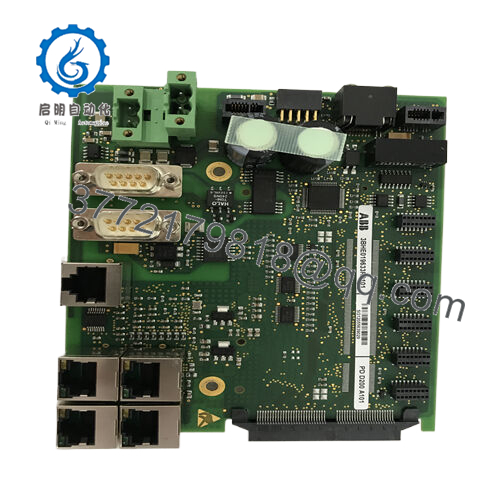

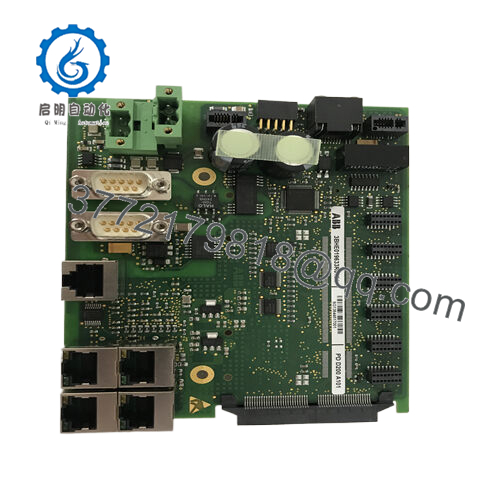

| Model Number | PDD200A101 |

| Brand | ABB |

| Type | Digital I/O Module |

| Input Voltage | 24V DC |

| Operating Temp Range | -40°C to +70°C |

| Mounting Style | DIN Rail |

| Dimensions | 110mm x 85mm x 65mm |

| Weight | Approx. 0.4 kg |

| Interface/Bus | PROFINET, Modbus |

| Compliance | CE, RoHS, UL 61010 |

| Supported Protocols | PROFINET IO, Modbus RTU/TCP |

| Typical Power Draw | 1.5W |

PDD200A101

The ABB PDD200A101 is a high-performance digital I/O module designed to serve as a critical interface between control systems and field devices in industrial settings. In manufacturing plants, where assembly lines rely on precise timing of conveyor belts, robotic arms, and actuators, the module ensures that digital signals are transmitted and received with minimal latency. In water and wastewater treatment facilities, it plays a vital role in controlling valves, pumps, and monitoring equipment, where any signal delay can disrupt the treatment process. The ABB PDD200A101 guarantees reliable signal transmission, making it an essential component for maintaining operational efficiency and productivity across various industrial sectors.

PDD200A101

As a key component in the automation hierarchy, the ABB PDD200A101 integrates seamlessly with distributed control systems (DCS) and programmable logic controllers (PLCs). It acts as a central hub for digital signals, receiving commands from the control system and sending them to field devices such as motors, solenoids, and indicators, while also relaying status information back to the control system. The module connects to the system backplane, enabling high-speed data exchange within the automation network. It supports standard industrial communication protocols, ensuring compatibility with a wide range of existing equipment. Additionally, the ABB PDD200A101 features advanced diagnostic functions that continuously monitor signal integrity and module health, providing real-time alerts for any anomalies, which helps in proactive maintenance and minimizing downtime.

PDD200A101

Main features and advantages:

The ABB PDD200A101 is engineered to deliver exceptional performance and reliability, translating into tangible benefits for industrial operations. Its rugged design allows it to operate flawlessly in extreme temperature conditions, from freezing cold to high heat, as well as in environments with high levels of vibration, dust, and humidity. This durability ensures a long service life, reducing the frequency of replacements and lowering maintenance expenses over time. The module’s high-speed signal processing capabilities minimize response times, enabling precise control of industrial processes and improving overall production efficiency.

Moreover, the ABB PDD200A101 simplifies system integration with its plug-and-play functionality and compatibility with multiple communication protocols. This reduces the time and effort required for installation and configuration, allowing engineers to focus on optimizing the automation system rather than troubleshooting compatibility issues. The advanced diagnostics features also contribute to operational efficiency by enabling quick identification and resolution of problems, minimizing unplanned downtime and keeping production lines running smoothly.

PDD200A101

Application areas:

The ABB PDD200A101 is widely deployed across various industries where reliable digital control is essential. In the automotive manufacturing sector, it is used in assembly lines to control robotic welding equipment, conveyor systems, and part handling mechanisms, ensuring precise and synchronized operation that is critical for maintaining product quality and production speed. In the food and beverage industry, the module helps control packaging machines, filling systems, and temperature regulators, adhering to strict hygiene and safety standards while ensuring efficient production.

In the mining and minerals industry, where harsh environmental conditions are prevalent, the ABB PDD200A101 reliably controls crushing equipment, conveyor belts, and material handling systems, contributing to uninterrupted operations and maximizing productivity. Its ability to withstand extreme conditions and provide accurate signal transmission makes it an ideal choice for critical applications where downtime is costly and safety is a top priority.

PDD200A101

Related products:

ABB PDD201A101 – A higher-density version with additional I/O channels for larger-scale applications.

ABB PDD200A102 – A variant with enhanced diagnostic capabilities for advanced troubleshooting needs.

ABB PDD190A101 – A cost-effective alternative suitable for less demanding industrial control applications.

ABB PDD200B101 – A model with extended temperature range for use in extremely harsh environments.

ABB PDD202A101 – A module with integrated surge protection for applications in areas with high electrical noise.

ABB PDD200A201 – A version with Modbus TCP/IP as the primary communication protocol for specific network setups.

ABB PDD210A101 – A high-performance model with faster response times for time-critical automation processes.

Installation and maintenance:

Before installing the ABB PDD200A101, ensure that the existing control system’s firmware is compatible with the module. Check the system documentation or consult ABB technical support to verify compatibility with your PLC or DCS model. Confirm that the power supply can deliver a stable 24V DC with the required current capacity to avoid voltage fluctuations that may affect module performance.

When mounting the module on a DIN rail, ensure there is adequate space around it for ventilation, as specified in the installation manual, to prevent overheating. Inspect the backplane connector for any damage or contamination before insertion to ensure a secure and reliable connection. During installation, take care to follow proper electrostatic discharge (ESD) precautions to protect the module’s sensitive electronics.

For ongoing maintenance of the ABB PDD200A101, regularly check the status LEDs on the front panel to monitor module health and communication status. A steady green power LED and communication LED indicate normal operation, while flashing or red LEDs may signal issues that require attention. Periodically inspect the wiring connections to ensure they are tight and free from corrosion, especially in humid or dusty environments.

It is recommended to update the module’s firmware at regular intervals using ABB’s software tools to access the latest performance improvements and bug fixes. Conduct a functional test of the module’s I/O channels annually to verify proper operation, and keep a record of maintenance activities to track the module’s performance over time.

Other ABB product models:

ABB FI840F

ABB FPR3203526R1002A

ABB FPR3600227R1202-J 07KR31

ABB FS300R12KE3/AGDR-72C

ABB FS450R12KE3/AGDR-71C

ABB FSA80

ABB G2000A5.7ST

ABB GCC960C102 3BHE033067R0102

ABB GDB021BE HIEE410455P104

ABB GDB021BE01 HIEE300766R0001

ABB GDC801B 3BHE051592R0101

ABB GDC801B102 3BHE051592R0102

ABB GFD233A 3BHE022294R0101

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GJR5252300R0101 07AC91

ABB GJR5252300R3101 07AC91

ABB GJR5252300R3101 07AC91

ABB GJR5253100R0270 07KT98

ABB GLBS200516R

ABB GMKP2800-32IBY

ABB GNT0104500R0002

ABB GRBTU 3BSE013175R1

ABB GVC750BE101 3BHE009681R0101 GVC750BE101 3BHE013088R001 5SHY3545L0010

ABB HAI805

ABB HBFFAEAGNBA1BAA11G

ABB HBS01-EPD

ABB HC800

ABB HESG112548R12

ABB HESG324430R11/B 216GD61A

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626