Description

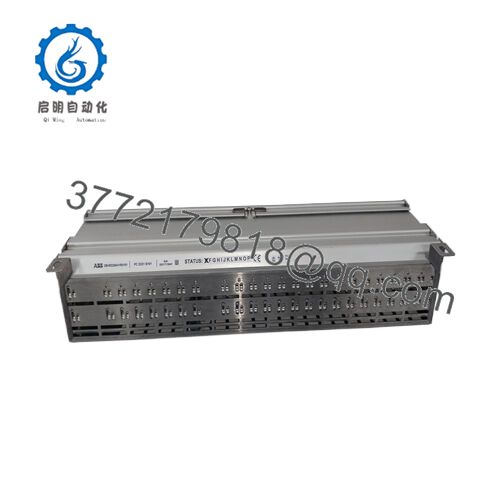

PCD231B101 Product Description:

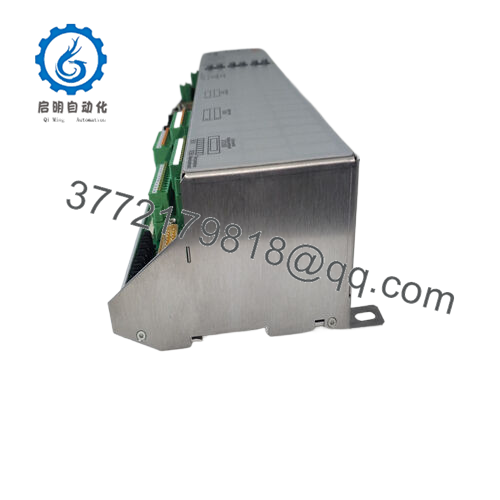

PCD231B101 is a high-performance I/O module that can be smoothly integrated into various industrial control platforms. It connects with other devices through a sturdy backplane system, achieving efficient data exchange and communication. This module supports industry standard protocols such as Profibus and CANopen, ensuring compatibility with diverse automation ecosystems. It has advanced built-in diagnostic functions that can continuously monitor the health and performance of each I/O channel. This enables engineers to quickly detect and solve any problems, preventing potential system failures. PCD231B101 can also be configured with redundant functions to provide additional reliability assurance for critical applications. In the I/O layer of automation architecture, it serves as a bridge between sensors, actuators, and central control units, converting physical signals into digital data at precise and fast speeds, and vice versa.

PCD231B101

Technical specifications:

Model PCD231B101

Brand ABB

Type I/O module

Input voltage 24 VDC

Working temperature range -20 ° C to 60 ° C

Installation method: DIN rail installation

Dimensions 120mm x 90mm x 70mm

Weight 0.6 kilograms

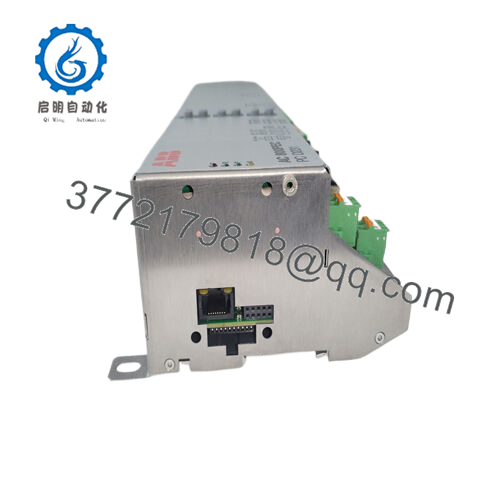

Interface/Bus Profibus, CANopen

Certification CE, RoHS

Supports protocols Profibus DP, CANopen, Modbus RTU

Typical power consumption of 12 W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

PCD231B101

Main features and advantages:

Choosing PCD231B101 means choosing a solution aimed at providing long-term performance and efficiency. Its high reliability ensures minimal interference to industrial processes, thereby improving productivity and reducing operational costs associated with downtime. The advanced diagnostic function of this module significantly reduces engineering costs by simplifying the troubleshooting process. Technicians can quickly identify and solve problems, minimizing the impact on production plans. In addition, it is compatible with multiple industrial protocols and can be easily integrated into existing automation systems without the need for large-scale system modifications. This easy to integrate feature, coupled with its robust performance, makes the PCD231B101 an excellent choice for engineers aiming to upgrade or expand industrial automation settings without sacrificing reliability or performance.

PCD231B101

Application areas:

PCD231B101 has been widely used in multiple industries. In the field of energy, especially in power plants, it plays a crucial role in monitoring and controlling electrical systems to ensure stable electricity production and distribution. It can operate under harsh conditions such as high temperature and electrical noise, making it a reliable choice for these demanding applications. In the manufacturing industry, especially on automotive assembly lines, PCD231B101 is used to manage the I/O signals of robotic arms, conveyors, and quality inspection sensors, achieving precise and efficient production processes. In addition, in the food and beverage industry, it helps to strictly control temperature, humidity, and ingredient dosage to ensure product quality and safety.

PCD231B101

Related product introduction:

PCD231B102: Provides more I/O channel capacity, suitable for a wider range of automation projects.

PCD231B100: An economical alternative product with basic I/O functionality, suitable for simpler applications.

PCD232B101: Equipped with enhanced signal processing capabilities, suitable for high-precision control tasks.

PCD231C101: Equipped with additional communication interfaces to provide greater connectivity flexibility.

PCD231B103: Designed with improved electromagnetic interference resistance, suitable for noisy industrial environments.

PCD230B101: An early model suitable for upgrading old systems that require basic I/O.

PCD233B101: Contains advanced security features for protecting sensitive industrial automation systems.

PCD231B101

Installation and maintenance:

Before installing PCD231B101, it is necessary to verify the compatibility between the bus system and existing equipment in the automation network. Ensuring that the power supply meets the module’s 24 VDC requirements and providing sufficient space to ensure proper ventilation to prevent overheating are also critical steps. In addition, it is recommended to check the firmware version against the manufacturer’s latest release version and update it if necessary to avoid any compatibility issues.

In daily maintenance, regularly checking the LED status indicator lights on the module can provide valuable information about its operating status. Regularly checking the connectors for signs of wear or looseness can prevent intermittent signal issues. Regular comprehensive system testing, including checking protocol integrity and signal accuracy, helps maintain optimal performance of PCD231B101 throughout its lifespan.

Other product models of ABB brand:

ABB unitrol1000-7 3BHE016011R0006

ABB UNITROL1010 3BHE035301R1002

ABB UNITROL1010-0410

ABB UNITROL1020 3BHE030579R0006

ABB UNITROL1020 UNS0119A-Z,V1 3BHE030579R000

ABB XUD194 XUD194A 3BHC018137R0001

ABB XV5628A

ABB Y129740-002

ABB YPI105C

ABB YPK112A 3ASD573001A13

ABB YPO104

ABB YPP-105F(YT204001)

ABB YPP110

ABB YPQ110A

ABB YPQ110A 3ASD573001A5

ABB С-093H

ABB PCD231

ABB HIEE300661R0001 UPC090AE01

ABB FMT200-ECO2

ABB 3BHB040253R0001

ABB SC520M 3BSE016237R1

ABB REC670 1MRK004814-AG

ABB TGM5 P14436-1072510

ABB GOP2000

ABB GOP2010

ABB 3BHE030579R0003

ABB 1SVR040000R1700

ABB DCF506-0140-51-0000000

ABB PCD530

ABB 1TGE120016R0104

ABB 1MRK000614-AB

ABB 5SHY35L4510

ABB PYT0450W071A

ABB 3BSE003832R1 SC510

ABB LM200

ABB SPAJ110C

ABB 1KHL178016R0001F

ABB 1KHL160038R0104D

ABB UP10C01000

ABB LD800HSE 3BDH000320R02

ABB 5SHY35L4520 5SXE10-0181

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626