Description

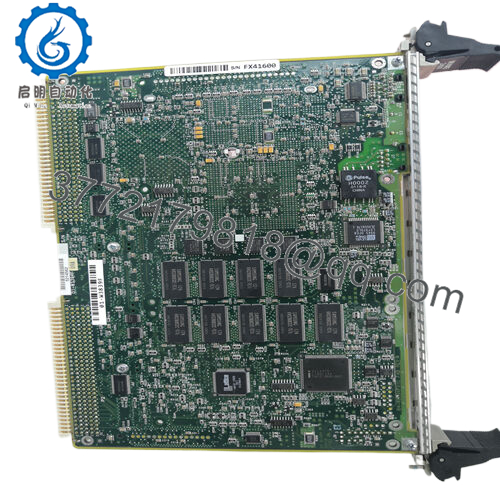

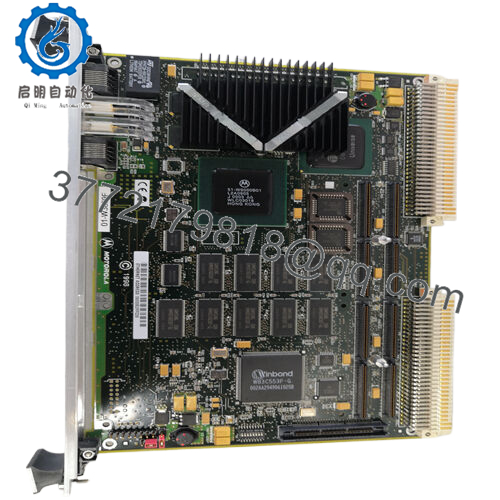

Product Model: Motorola MVME2400

Product Brand: Motorola

Product Series: MVME Series (VMEbus Single-Board Computers)

Product Features:

- PowerPC-based embedded computing platform for VMEbus systems

- Dual Ethernet ports, multiple serial interfaces, and SCSI support

- Ideal for real-time industrial control, automation, and defense systems

- Proven reliability and extended life-cycle support from Motorola’s MVME family

- MVME2400

Product Role & System Fit

The Motorola MVME2400 is a mid-generation PowerPC-based VMEbus single-board computer (SBC) that bridges legacy VME infrastructure with modern embedded computing performance. Within a multi-slot VME chassis, this board typically operates as the primary system controller, orchestrating I/O, executing control logic, and communicating across the plant or network.

Equipped with a PowerPC 750 processor and up to 512 MB of DRAM, the MVME2400 offers solid computational throughput for deterministic workloads. It integrates a wide range of communication interfaces—dual 10/100Base-T Ethernet, serial ports, and Ultra SCSI—to ensure compatibility with diverse field equipment. Its flexible PMC (PCI Mezzanine Card) slots allow system integrators to customize the board with additional I/O, fieldbus adapters, or specialized co-processors.

In many industrial and defense applications, reliability matters more than raw speed. That’s where the MVME2400 excels. Its ruggedized PCB layout, conformal coating options, and built-in watchdog timers give it staying power in demanding environments—from high-vibration factory floors to temperature-variable control rooms.

Compatibility has always been a cornerstone of Motorola’s VME design philosophy. The MVME2400 maintains pin-level and software continuity with older MVME162 and MVME177 modules, enabling phased modernization projects without requiring a total system overhaul. Engineers can port proven real-time code or OS images with minimal modification, preserving certification and validation cycles.

Applications & Industry Context

In the world of industrial automation, embedded control, and defense electronics, the Motorola MVME2400 has earned a strong reputation as a dependable platform. Its use spans industries where continuous uptime and deterministic control are critical.

Manufacturing & Automation:

Factory automation systems rely on synchronized control between motion drives, sensors, and supervisory networks. The MVME2400 serves as a deterministic controller at the heart of robotic assembly lines, coordinate measurement machines, and material-handling equipment. Its low interrupt latency ensures precise real-time response.

Energy and Utilities:

In power generation and distribution, reliability and temperature resilience are essential. Many utilities deploy the MVME2400 in turbine control panels, switchgear management, and substation automation. The board’s extended operating range and solid power stability ensure it can endure 24/7 service in challenging environments.

Defense and Aerospace:

Mission-critical systems often rely on VMEbus due to its proven electrical robustness and deterministic backplane timing. The MVME2400 powers data acquisition, radar processing, and flight simulation systems in both land-based and airborne applications. Its long lifecycle support minimizes the logistical burden of requalification—a decisive advantage for defense integrators.

Telecommunications & Networking:

In legacy telecom infrastructure, the MVME2400 operates as a control processor in base stations, satellite gateways, and packet-switching nodes. Its dual Ethernet and SCSI connectivity make it a capable bridge between older TDM systems and modern IP-based management networks.

In each of these environments, the same principles apply: the MVME2400 delivers stable performance, predictable timing, and a build quality that has made the MVME family a benchmark in embedded reliability.

Technical Features & Benefits

Motorola designed the MVME2400 with a clear focus on industrial-grade dependability and forward-compatible performance. Its PowerPC 750 microprocessor runs at clock speeds between 400 and 500 MHz, providing a strong balance of processing efficiency and low thermal footprint. The processor’s superscalar architecture supports simultaneous instruction execution, ideal for multitasking real-time applications.

System memory architecture includes up to 512 MB of ECC DRAM for main program storage and Flash memory for firmware or bootloaders. ECC (Error-Correcting Code) memory automatically detects and corrects single-bit errors—an essential feature for embedded control systems operating without operator supervision.

For connectivity, the MVME2400 provides two 10/100 Ethernet interfaces, three serial ports (configurable for RS-232/422), a parallel port, and a high-speed SCSI interface. This wide I/O spectrum ensures it can serve as a hub in both legacy and modern equipment networks. The board also supports PMC expansion cards, offering flexibility to integrate fieldbus protocols like CANopen, Profibus, or ARINC for specialized environments.

On the software side, compatibility with VxWorks, LynxOS, and embedded Linux makes it developer-friendly. Motorola’s board support packages (BSPs) simplify integration with real-time operating systems, shortening deployment time.

Additional technical advantages include:

- Hardware watchdog for automatic recovery in case of application lock-up

- Onboard timers and interrupt controllers optimized for deterministic response

- Flash-resident boot firmware supporting network and local boot options

- Diagnostic LEDs and accessible jumpers for quick system configuration

Together, these design attributes ensure the MVME2400 delivers industrial reliability, system-level flexibility, and sustained performance even in harsh operating conditions.

Technical Specifications

| Specification | Details |

|---|---|

| Processor | PowerPC 750 microprocessor |

| Clock Speed | 400 – 500 MHz |

| Main Memory | Up to 512 MB ECC DRAM |

| Flash Memory | 32 MB onboard for firmware |

| Bus Standard | VMEbus (IEEE 1014 compliant) |

| I/O Interfaces | 2 × Ethernet (10/100Base-T), 3 × Serial (RS-232/422), Ultra SCSI, Parallel Port |

| Expansion Options | 2 × PMC (PCI Mezzanine Card) slots |

| Supported OS | VxWorks, LynxOS, Embedded Linux |

| Power Input | +5 V DC nominal |

| Cooling Requirement | Forced-air cooling recommended |

| Form Factor | 6U VME Single-Board Computer |

| Operating Temperature | 0 °C to 55 °C standard; -40 °C to 70 °C extended |

| Compliance | CE, UL, MIL-STD environmental ratings |

Installation & Maintenance Insights

Installing the Motorola MVME2400 follows standard VME procedures but benefits from methodical attention to detail. Begin by verifying slot addressing and jumper configurations to avoid conflicts with existing bus controllers. Align the card guides before insertion and apply even pressure—never force the board into the backplane, as misalignment can damage connectors.

Power requirements are straightforward. A regulated +5 V DC supply with minimal ripple ensures stable operation. Because PowerPC boards can generate moderate heat, maintain consistent airflow through the chassis. Many integrators add temperature sensors or fans tied to control relays for automatic cooling management.

Maintenance over time is simple yet crucial. Dust removal, periodic inspection of connector contacts, and verification of grounding integrity extend lifespan. Regular monitoring of the onboard diagnostic LEDs can quickly reveal hardware faults or boot issues. Firmware upgrades are done via serial or Ethernet console using standard boot protocols.

For critical systems, many operators keep preconfigured MVME2400 spares ready for hot-swap replacement. This approach minimizes downtime and ensures fast restoration in the rare event of failure. The board’s robust design and stable firmware environment make such interventions infrequent but straightforward.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626