Description

The Motorola MVME550-163 functions as a high-performance processing hub in VMEbus architectures, combining a powerful RISC processor with enhanced I/O capabilities to support modern industrial networks. Unlike older MVME series modules, it integrates seamlessly with both legacy VMEbus backplanes (IEEE 1014-compliant) and emerging industrial Ethernet standards, making it a versatile choice for facilities in transition from traditional to smart systems.

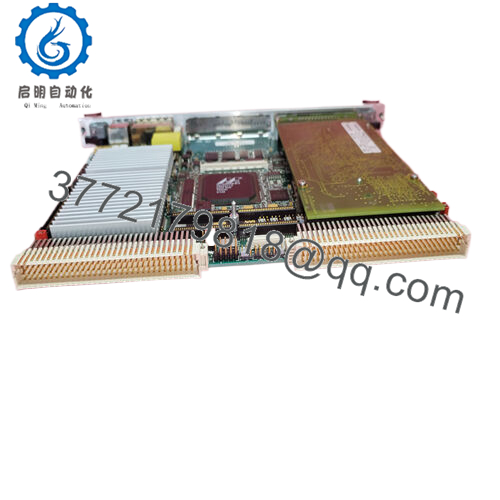

MVME550-163

The Motorola MVME550-163 features dual-core processing, allowing it to simultaneously handle real-time control tasks and data logging/analytics—eliminating the need for separate modules that introduce latency. It supports a range of advanced protocols, including PROFINET and Modbus TCP/IP, ensuring compatibility with smart sensors, IoT gateways, and cloud-based supervisory systems. Additionally, its enhanced memory architecture includes error-correcting code (ECC) RAM, which prevents data corruption in high-electrical-noise environments—a critical feature for maintaining data integrity in industrial settings.

MVME550-163

Technical specifications:

Model Number MVME550-163

Brand Motorola

Type High-Performance VMEbus Single-Board Computer

Input Voltage +5V DC, +3.3V DC

Operating Temp Range -40°C to 70°C (-40°F to 158°F)

Mounting Style 6U VMEbus backplane mount

Dimensions 233mm x 160mm (9.17in x 6.30in)

Weight 680g (24.0oz)

Interface/Bus VMEbus (32/64-bit), 2x Gigabit Ethernet

Compliance CE, UL 61010-1, RoHS, ATEX Zone 2

Supported Protocols PROFINET, Modbus TCP/IP, EtherCAT, RS-485

Typical Power Draw 35W (max)

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

MVME550-163

Main features and advantages:

Choosing the Motorola MVME550-163 delivers tangible benefits that extend beyond raw processing power. Its dual-core architecture ensures that critical control loops—such as those regulating temperature in chemical reactors or speed in precision manufacturing—remain responsive even while the module simultaneously logs data for analytics, eliminating the trade-off between real-time operation and data collection. The ECC RAM feature reduces the risk of costly errors in data-driven decision-making, ensuring that analytics platforms receive accurate information from the field. For engineers, the Motorola MVME550-163 simplifies the transition to smart manufacturing: its backward compatibility with legacy VMEbus components allows for incremental upgrades, while its support for modern protocols ensures it can integrate with new IoT devices as the system evolves. This flexibility reduces the total cost of ownership by extending the life of existing infrastructure while enabling future expansion.

MVME550-163

Application areas:

The Motorola MVME550-163 is deployed in industries where high performance and connectivity are critical to operational success. In smart automotive plants, it serves as the processing core for adaptive manufacturing cells, coordinating robot movements, vision systems, and inventory tracking via industrial Ethernet—adjusting production in real time based on incoming orders or supply chain changes. Its ATEX compliance makes it suitable for use in hazardous areas of pharmaceutical manufacturing, where it controls sterile processing equipment while logging data to ensure regulatory compliance. In renewable energy facilities, such as wind farms, the Motorola MVME550-163 manages turbine control systems, processing data from vibration sensors and weather monitors to optimize performance while transmitting analytics to a central management platform. Its extended temperature range allows it to operate reliably in unconditioned enclosures, reducing the need for climate-controlled cabinets in remote locations.

Related products:

MOTOROLA MVME2604 712

Motorola MVME3100

Motorola MVME162PA-244LS

Motorola MVME5110-2261

Motorola MVME5100

Motorola MVME5100

MOTOROLA MVME6100

MOTOROLA MVME55006E-0163R

MOTOROLA MVME5500-0163

Motorola MVME5100

MOTOROLA MVME 147-011

MOTOROLA MVME 215-1

Motorola MVME162-014

Motorola MVME162PA-344SE

motorola MVME2432

MOTOROLA MVME61006E-0161

MOTOROLA MVME61006E-0163

Motorola MVME162-213

Motorola MVME162-213

MOTOROLA MVME61006E-0163

MOTOROLA MVME5100

Motorola IPMC761-002

Motorola IPMC761-002

MOTOROLA MVME5500

MOTOROLA MVME3100

Motorola MVME147-012

MOROTOLA MVME147SA-1

MOTOROLA MVME5100

MOTOROLA MVME5100

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626