Description

Real-World Use & Application Scenarios

The Motorola MVME550-163 is engineered for industrial automation, embedded control, and real-time processing environments where high reliability, precision, and durable performance are essential. Widely deployed in sectors like manufacturing automation, aerospace control systems, and defense electronics, this module addresses challenges such as real-time data acquisition, control loop execution, and critical communication tasks. It is particularly used in complex control racks and VMEbus-based systems where integration with diverse I/O interfaces and stringent uptime is crucial. The Motorola MVME550-163 enables engineers to meet demanding process control requirements through consistent operation in harsh industrial conditions including temperature fluctuations, vibrations, and electromagnetic interference.

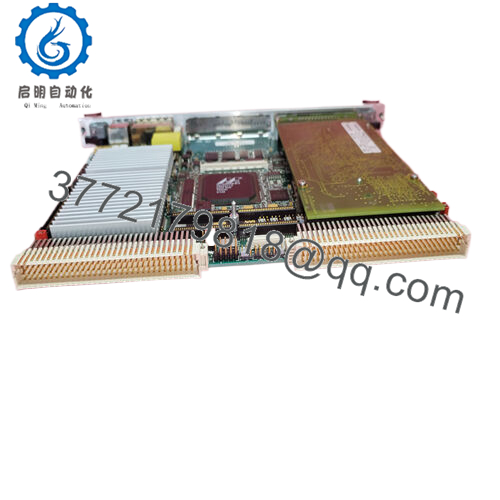

Product Introduction & Positioning

The Motorola MVME550-163 is a rugged, single-slot VMEbus processor module centered around the PowerPC processor architecture. It provides substantial computing power paired with advanced memory management and fault-tolerant features, making it ideal for embedding into large industrial control systems or mission-critical applications. This module plays the role of a high-performance computing node within VMEbus platforms, coordinating communication between I/O boards, network connections, and control algorithms. It supports integration with Programmable Mezzanine Cards (PMC) for flexible I/O expansions and is compatible with legacy and modern VMEbus systems, making it a core building block for scalable control architectures.

Key Technical Features & Functional Benefits

Powered by a PowerPC series processor (specific variants depending on configuration), the MVME550-163 balances clock speed, cache size, and memory connectivity to optimize control task execution and system responsiveness. Its onboard ECC-protected memory offers robust error detection and correction capabilities, indispensable for reliability in environments susceptible to electrical noise and physical disturbances.

This module supports two PMC expansion slots for scalable industrial I/O options and features Ethernet and serial interfaces for network and peripheral connectivity. The MVME550-163 includes watchdog timers and real-time clock functions to maintain system integrity and uptime, plus hardware diagnostics aid in fault detection and rapid issue resolution. The board fits within standard VME chassis with rugged mounting and cooling provisions, ensuring long-term operational stability.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | Motorola MVME550-163 |

| Brand | Motorola |

| Product Type | Single Board Computer (VMEbus module) |

| Processor | PowerPC-based processor (varies by configuration) |

| Processor Speed | Typically in the 200-400 MHz range |

| Memory | ECC-protected SDRAM (size varies) |

| PMC Expansion Slots | Two 32/64-bit PCI Mezzanine Card slots |

| Network Interfaces | Ethernet (10/100/1000 Mbps variants possible) |

| Serial Interfaces | Multiple asynchronous and synchronous serial ports |

| Timers and Watchdog | Hardware watchdog and multiple timers |

| Real-Time Clock | Battery-backed NVRAM and RTC |

| Operating Temperature | Industrial range, typically 0° to 70°C or higher depending on cooling |

| Dimensions | Standard single-width VME form factor |

| Weight | Approximately 0.5 kg |

| Cooling | Forced air cooling recommended |

| Certifications | Industrial-grade certifications (FCC, CE) |

- MVME550-163

Related Modules or Compatible Units

MVME550-230 – Similar processor module with enhanced memory and clock speed.

MVME550-233 – Higher-performance variant with increased cache and expanded I/O.

MVME2700-761 – Advanced PowerPC single board computer with additional connectivity options.

MVME2432 – PowerPC 750-based VMEbus SBC for mid-range control applications.

MVME162-213 – Compact MC68060 VME SBC optimized for embedded control.

MVME177 – High-performance VMEbus processor module designed for demanding industrial control.

Installation Notes & Maintenance Best Practices

Installation requires a VME chassis supporting single-slot modules, with sufficient airflow and grounding provisions to mitigate EMI. Forced air is preferred to maintain thermal compliance. Secure and shield all external connections and PMC cards to ensure signal quality and system stability. Allow adequate space around the module for servicing and upgrades.

Maintenance includes routine inspection of connectors, cleaning of fans and air channels, and monitoring system diagnostics for proactive fault detection. Firmware and software should be updated periodically in line with manufacturer guidance to maintain reliability and security. Detailed logging of firmware versions and hardware configurations aids troubleshooting and compliance.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626