Description

The Motorola MVME2301-900 functions as a specialized processing core within 3U VMEbus architectures, combining the space efficiency of the MVME2100 with the advanced capabilities of the MVME2301 series. Like its predecessors, it fits seamlessly into IEEE 1014-compliant VMEbus backplanes, ensuring compatibility with existing 3U infrastructure while introducing a dedicated coprocessor for real-time control tasks.

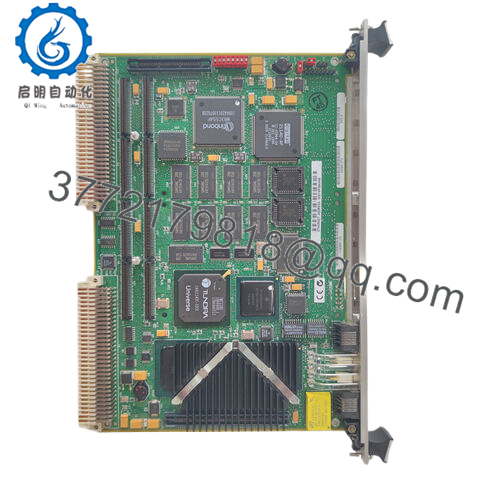

MVME2301-900

This design allows the Motorola MVME2301-900 to handle both general automation processing and specialized functions—such as high-speed data acquisition or proprietary control algorithms—simultaneously, eliminating the need for external modules in tight enclosures. It supports an expanded range of industrial protocols, including PROFINET, EtherCAT, and custom serial interfaces, making it interoperable with both legacy sensors and cutting-edge smart devices. Additionally, its ruggedized construction exceeds standard industrial ratings, with enhanced resistance to shock, vibration, and extreme temperatures—critical for applications in mining, construction, or outdoor energy systems.

MVME2301-900

Technical specifications:

Model Number MVME2301-900

Brand Motorola

Type Specialized 3U VMEbus Single-Board Computer

Input Voltage +5V DC, +3.3V DC, ±12V DC

Operating Temp Range -55°C to 85°C (-67°F to 185°F)

Mounting Style 3U VMEbus backplane mount with locking clips

Dimensions 100mm x 160mm (3.94in x 6.30in)

Weight 380g (13.4oz)

Interface/Bus VMEbus (64-bit), 2x Gigabit Ethernet, 8x RS-485

Compliance CE, UL 61010-1, RoHS, ATEX Zone 1, IEC 60068-2

Supported Protocols PROFINET, EtherCAT, Modbus TCP/IP, CANopen, Custom Serial

Typical Power Draw 32W (max)

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

MVME2301-900

Main features and advantages:

Choosing the Motorola MVME2301-900 delivers distinct advantages for engineers working on specialized, space-constrained systems. Its dedicated coprocessor ensures that critical real-time tasks—such as precision timing in robotic assembly or rapid response in safety-critical control loops—are executed without latency, even when the main processor is handling data logging or communication. This separation enhances system reliability, a key benefit in applications where downtime is costly or dangerous. The Motorola MVME2301-900’s extended operating temperature range (-55°C to 85°C) allows it to operate in environments that would disable standard compact modules, from Arctic oil fields to desert solar installations, reducing the need for expensive environmental enclosures. For facilities with mixed 3U and 6U systems, its backward compatibility with MVME2100 peripherals and MVME2301 software tools simplifies integration, allowing engineers to leverage existing infrastructure and expertise.

MVME2301-900

Application areas:

The Motorola MVME2301-900 is deployed in specialized applications where compact size, advanced processing, and ruggedness are equally critical. In military ground vehicles, such as armored personnel carriers, it serves as the control core for navigation and weapons systems, processing data from GPS, inertial sensors, and targeting cameras—all within the tight electrical enclosures of mobile platforms. Its ATEX Zone 1 compliance makes it suitable for use in explosive environments, such as offshore oil rigs, where it manages compact pumping systems and processes data from pressure sensors while withstanding harsh weather and vibration. In precision semiconductor manufacturing, the Motorola MVME2301-900 controls compact ion implantation equipment, executing specialized algorithms to regulate beam intensity and wafer positioning with nanometer precision, all within the space constraints of cleanroom enclosures.

Related products:

MOTOROLA MVME2604 712

Motorola MVME3100

Motorola MVME162PA-244LS

Motorola MVME5110-2261

Motorola MVME5100

Motorola MVME5100

MOTOROLA MVME6100

MOTOROLA MVME55006E-0163R

MOTOROLA MVME5500-0163

Motorola MVME5100

MOTOROLA MVME 147-011

MOTOROLA MVME 215-1

Motorola MVME162-014

Motorola MVME162PA-344SE

motorola MVME2432

MOTOROLA MVME61006E-0161

MOTOROLA MVME61006E-0163

Motorola MVME162-213

Motorola MVME162-213

MOTOROLA MVME61006E-0163

MOTOROLA MVME5100

Motorola IPMC761-002

Motorola IPMC761-002

MOTOROLA MVME5500

MOTOROLA MVME3100

Motorola MVME147-012

MOROTOLA MVME147SA-1

MOTOROLA MVME5100

MOTOROLA MVME5100

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626