Description

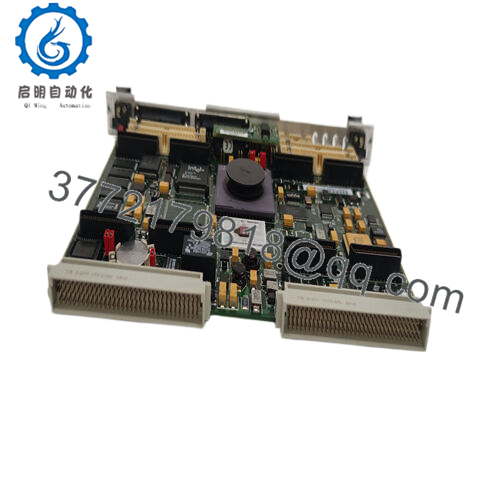

The Motorola MVME162PA-344E functions as a high-performance processing core within VMEbus-based industrial control systems, serving as the central hub for data aggregation, analysis, and command execution. It integrates seamlessly with a wide range of I/O modules, sensors, and actuators, communicating via industry-standard protocols to ensure interoperability with both legacy and modern system components. Unlike its predecessors, this module features enhanced processing architecture that reduces data latency—critical for time-sensitive applications like motion control or precision dosing in chemical processing.

MVME162PA-344E

like motion control or precision dosing in chemical processing. The Motorola MVME162PA-344E connects to VMEbus backplanes (compliant with IEEE 1014 standards), enabling it to fit into existing infrastructure without requiring extensive system overhauls. It also includes advanced diagnostic capabilities, with onboard LEDs and error-logging features that provide instant visibility into operational status, allowing engineers to quickly identify and resolve issues before they escalate into downtime events. This combination of processing power and diagnostic intelligence makes it a linchpin in industrial automation stacks where reliability and efficiency are paramount.

MVME162PA-344E

Technical specifications:

Model Number MVME162PA-344E

Brand Motorola

Type Enhanced Single-Board Computer (VMEbus)

Input Voltage +5V DC, ±12V DC, +3.3V DC

Operating Temp Range -40°C to 70°C (-40°F to 158°F)

Mounting Style VMEbus backplane mount (3U form factor)

Dimensions 100mm x 160mm (3.94in x 6.30in)

Weight 380g (13.4oz)

Interface/Bus VMEbus (IEEE 1014-1987, ANSI/IEEE 1101.1)

Compliance CE, UL 60950-1, RoHS, ATEX Zone 2

Supported Protocols RS-232, RS-485, Ethernet/IP (via integrated port)

Typical Power Draw 15W (max)

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

MVME162PA-344E

Main features and advantages:

Choosing the Motorola MVME162PA-344E delivers tangible benefits that extend beyond basic functionality, directly impacting operational efficiency and long-term cost management. Its extended operating temperature range ensures reliable performance in extreme environments, from freezing cold storage facilities to high-heat industrial ovens, eliminating the need for costly environmental controls around the control cabinet. The module’s enhanced processing speed reduces latency in critical control loops, which translates to more precise adjustments in processes like batch mixing or conveyor speed regulation—ultimately improving product quality and reducing waste. Engineers also benefit from simplified integration: the Motorola MVME162PA-344Eis backward-compatible with older VMEbus systems, allowing for incremental upgrades rather than full system overhauls. This not only lowers initial investment costs but also minimizes downtime during transition, as existing I/O modules and software can be retained while gaining the performance benefits of the new processing core.

Application areas:

The Motorola MVME162PA-344E excels in applications where rugged performance and reliable data processing are mission-critical. In the oil and gas industry, it’s deployed in pipeline monitoring systems, processing data from pressure transducers and flow meters to detect leaks or pressure drops in real time—even in remote, unconditioned field enclosures where temperatures swing dramatically. Its ATEX compliance makes it suitable for hazardous areas, a key requirement in petrochemical facilities. In water and wastewater treatment plants, the Motorola MVME162PA-344E manages pump controls and chemical dosing systems, ensuring precise adjustments to pH levels and flow rates to meet regulatory standards. Additionally, in automotive manufacturing, it serves as the processing brain for robotic welding stations, coordinating sensor inputs and motor movements with microsecond precision to maintain weld quality and production throughput. In each of these settings, the module’s ability to operate reliably under stress ensures critical system uptime.

Related products:

For ongoing maintenance, schedule monthly visual inspections of the backplane connectors to remove dust or corrosion, which can cause intermittent communication errors. Quarterly firmware checks are recommended to ensure compatibility with updated I/O modules, and annual functional testing should include verifying all protocol interfaces to confirm consistent data transmission. The onboard LED status indicators should be reviewed during shift changes to catch early warning signs of issues like voltage irregularities or bus errors.

MOTOROLA MVME2604 712

Motorola MVME3100

Motorola MVME162PA-244LS

Motorola MVME5110-2261

Motorola MVME5100

Motorola MVME5100

MOTOROLA MVME6100

MOTOROLA MVME55006E-0163R

MOTOROLA MVME5500-0163

Motorola MVME5100

MOTOROLA MVME 147-011

MOTOROLA MVME 215-1

Motorola MVME162-014

Motorola MVME162PA-344SE

motorola MVME2432

MOTOROLA MVME61006E-0161

MOTOROLA MVME61006E-0163

Motorola MVME162-213

Motorola MVME162-213

MOTOROLA MVME61006E-0163

MOTOROLA MVME5100

Motorola IPMC761-002

Motorola IPMC761-002

MOTOROLA MVME5500

MOTOROLA MVME3100

Motorola MVME147-012

MOROTOLA MVME147SA-1

MOTOROLA MVME5100

MOTOROLA MVME5100

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626