Description

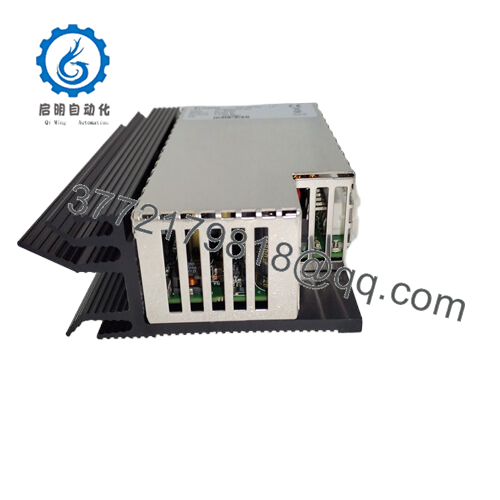

The Metso D201832 is an intelligent power supply and signal – handling module. It has the primary function of receiving and sending pulse signals, which is fundamental for controlling and monitoring industrial equipment. This module is engineered to interface effectively with a wide range of industrial control systems.

D201832

It can be easily integrated into existing setups, whether they are based on Programmable Logic Controllers (PLCs) or more complex Distributed Control Systems (DCS). Connecting to the backplane of the control system, it enables seamless communication with other I/O modules and the central processing unit. It operates on a stable power supply (with specific voltage details available in the full datasheet), ensuring consistent performance even in challenging industrial conditions.

D201832

Technical specifications:

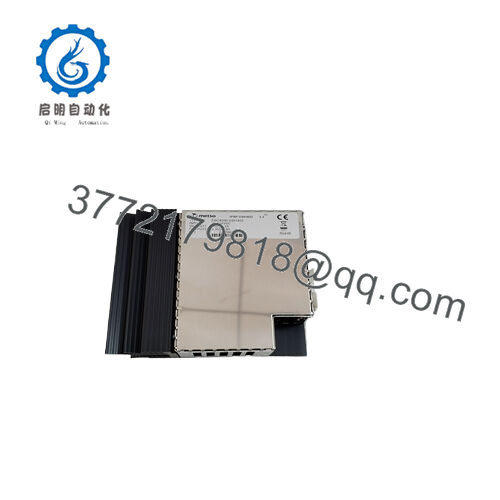

Model Number D201832

Brand Metso

Type Intelligent Power Supply and Signal – Handling Module

Compliance CE, UL, ensuring safety and quality standards are met

Supported Protocols Common industrial communication protocols for seamless integration

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

D201832

Main features and advantages:

Opting for the Metso D201832 offers numerous real – world benefits. Its high – reliability design is a major advantage. Built with quality components, it can withstand harsh industrial environments, including extreme temperatures, vibrations, and electromagnetic interference. This reliability leads to fewer system failures and reduced downtime, which is crucial for maintaining continuous production and minimizing costly disruptions. The module is also designed with user – friendliness in mind. Its installation process is relatively straightforward, allowing engineers and technicians to quickly integrate it into existing systems, reducing the time and effort required for setup. This ease – of – use also extends to maintenance, as the module’s design allows for simple troubleshooting and replacement of components if needed. Additionally, the MetsoD201832 provides flexibility in its application. It can be used in a wide variety of industrial processes, from basic signal – handling tasks to more complex systems that require precise control and monitoring.

D201832

Application areas:

The Metso D201832 finds applications across a diverse range of industries. In the automotive manufacturing industry, it can be used to manage the power supply and signal transmission for robotic arms and conveyor systems. By accurately handling pulse signals, it ensures the precise movement of robotic arms during the assembly process, contributing to high – quality car part assembly. In the food and beverage industry, the module can be deployed to control the filling and packaging machinery. It can manage the signals that regulate the operation of pumps, valves, and conveyors, ensuring the correct filling of products and proper packaging, thus maintaining product quality and safety. In the power generation sector, it can be used to control and monitor the power distribution system. By handling the signals related to the opening and closing of switches and the monitoring of electrical parameters, it helps ensure the stable supply of electricity and the efficient operation of power plants.

D201832

Related products:

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626