Description

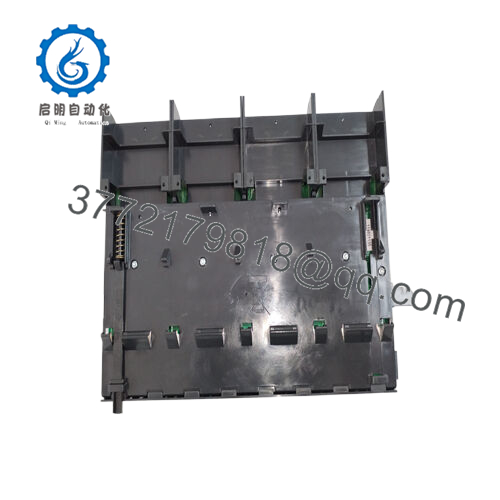

The Metso D201376 is an analog input module that serves as a fundamental building block in industrial automation systems. It is designed to interface with a wide range of sensors, converting their analog signals into digital data that can be easily processed by a PLC or other control devices. This module is highly adaptable and can be integrated into existing control platforms with relative ease. It connects to the backplane of a control system, allowing it to communicate with other I/O modules and the central processing unit.

D201376

For instance, in a distributed control system, the Metso D201376 can be used to collect data from multiple sensors located at different points in the process. It supports various industrial communication protocols, such as Modbus RTU/TCP, which enables seamless interaction with other devices in the network. This means that the data it acquires can be readily shared with SCADA systems for real – time monitoring and analysis. Additionally, the module is engineered to handle high – volume data input, making it suitable for large – scale industrial applications.

D201376

Technical specifications:

Model Number D201376

Brand Metso

Type Analog Input Module

Input Voltage 10 – 30 VDC

Operating Temp Range – 20°C to 60°C

Mounting Style DIN rail (35mm)

Dimensions Compact design for easy installation

Weight 0.75 kg

Interface/Bus Communication interfaces include options like Modbus RTU/TCP

Compliance CE, UL

Supported Protocols Modbus RTU/TCP

Typical Power Draw Designed to be power – efficient

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

D201376

Main features and advantages:

Opting for the Metso D201376brings about several real – world benefits. Firstly, its high – precision data acquisition capabilities ensure that the control system makes decisions based on accurate information. This is critical in applications where even a slight deviation in sensor readings can have significant consequences, such as in pharmaceutical manufacturing, where precise control of process variables is essential for product quality. The module is engineered for reliability, with components that can withstand the rigors of industrial environments. This reduces the need for frequent maintenance and replacement, ultimately cutting down on operational costs. Its ability to integrate seamlessly with existing systems also means that there is no need for a complete overhaul of the automation setup, saving both time and money. The Metso D201376 is also future – proofed to some extent, as it can be easily upgraded or expanded as the industrial process evolves and new requirements arise.

D201376

Application areas:

The Metso D201376 finds applications in multiple industries. In the power generation sector, it can be used to monitor the temperature, pressure, and vibration of turbines. By accurately collecting this data, operators can predict potential equipment failures and schedule maintenance proactively, ensuring the continuous operation of power plants. In the automotive manufacturing industry, the module can be deployed to monitor the quality of welding processes. Sensors measuring parameters like current, voltage, and weld time can be connected to the Metso D201376, and the data can be used to adjust the welding process in real – time, improving the quality of the final product. In food and beverage production, the module can be used to monitor the temperature and pressure during the bottling or packaging process, ensuring product safety and quality.

D201376

Related products:

D201375 – A lower – cost alternative with a slightly reduced number of input channels, suitable for smaller – scale applications where budget is a constraint.

D201377 – An upgraded version with enhanced noise – filtering capabilities, ideal for environments with high electromagnetic interference.

DI801 – S – A digital input module that can be used in combination with the D201376 for systems that require both analog and digital data acquisition.

DO802 – S – A digital output module that can work in tandem with the D201376, allowing for more comprehensive control over the industrial process.

AI810 – S – Another analog input module with different input ranges, useful for applications where the D201376’s standard input range may not be sufficient.

AO50 – An analog output module that can be integrated into the system when there is a need to control devices based on the data acquired by the D201376.

CM574 – ETH – A communication module that can be used to expand the networking capabilities of the system where the D201376 is installed.

Installation and maintenance:

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626