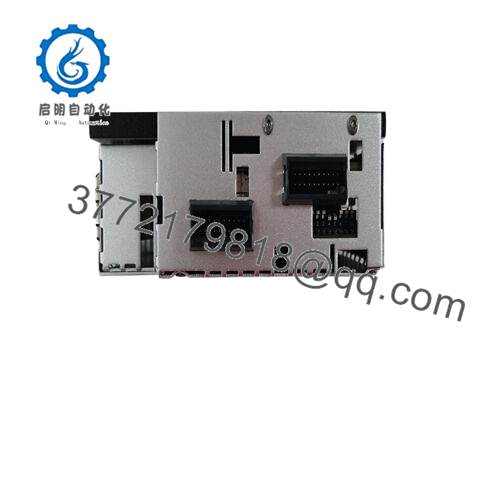

Description

The Metso D201291 serves as a central data integration and processing hub within an industrial automation system. It’s designed to interface with a wide range of sensors and actuators, regardless of the protocol they use. This is achieved through its advanced communication capabilities, which support multiple industrial protocols such as Profibus, Modbus, and Ethernet/IP. It can be easily integrated into existing control platforms, acting as a bridge between different components of the automation stack. For example, it can connect to a PLC – based control system via the backplane, collecting data from various I/O modules and then processing and transmitting this data to a SCADA system for monitoring and control.

D201291

The module also features built – in redundancy mechanisms. In critical industrial applications, a single point of failure can have disastrous consequences. The Metso D201291 addresses this by having redundant power supplies and communication channels. This means that in the event of a component failure, the system can continue to operate without interruption, ensuring continuous uptime in processes like oil and gas production, where any stoppage can lead to significant financial losses. Additionally, it has advanced diagnostic capabilities. It can constantly monitor its own performance and that of the connected devices, providing early warnings of potential issues. This not only helps in preventing unplanned downtime but also in optimizing maintenance schedules.

D201291

Technical specifications:

Model Number D201291

Brand Metso

Type Data Integration and Processing Module

Input Voltage 24 VDC ±10%

Operating Temp Range – 20°C to +55°C (-4°F to +131°F)

Mounting Style DIN rail (35mm)

Dimensions 100mm x 130mm x 90mm (W x H x D)

Weight 350g

Interface/Bus Profibus, Modbus, Ethernet/IP, and more

Compliance CE, UL

Supported Protocols Multiple industrial protocols

Typical Power Draw 6W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

D201291

Main features and advantages:

D201291

Application areas:

D201291

Related products:

D201290 – A lower – cost version with slightly reduced processing power, suitable for smaller – scale operations.

D201292 – An upgraded model with enhanced memory capacity for handling larger volumes of data.

D201289 – An older – generation unit with basic data integration capabilities, useful for legacy system upgrades.

DI – 100 – A digital input module that can be used in conjunction with the D201291 for expanding input capabilities.

DO – 101 – A digital output module for controlling actuators in the system, compatible with the D201291.

AI – 50 – An analog input module for connecting sensors that provide analog signals, works well with the D201291.

AO – 51 – An analog output module for controlling devices that require analog control signals, can be integrated with the D201291.

D201291

Installation and maintenance:

Before installing the Metso D201291, it’s essential to check the compatibility of the existing bus system with the module. Ensure that the DIN rail on which it will be mounted is in good condition and has enough space for proper ventilation. Also, verify that the firmware of the module is up – to – date. This can be done through Metso’s official software update tools. Make sure that the power supply to the module meets the specified requirements, and all the necessary cables for communication and power connections are of the correct type and length.

For ongoing maintenance, regularly check the status LEDs on the module. A steady green LED indicates normal operation, while any flashing or red LEDs may signal an issue. Periodically inspect the connectors for any signs of wear, corrosion, or looseness. Once a year, perform a comprehensive system test using Metso’s diagnostic software. This test can help in identifying any potential issues with the module’s performance or its connection with other devices in the system.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626