Description

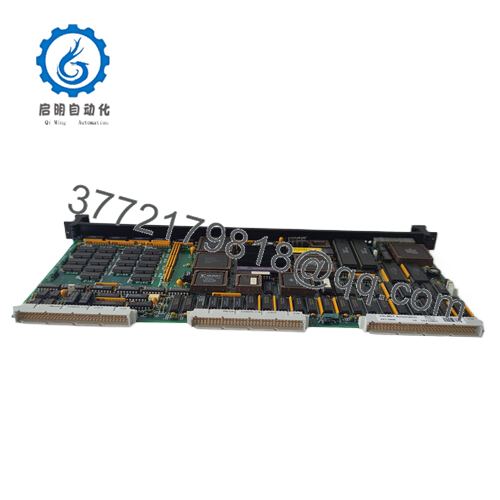

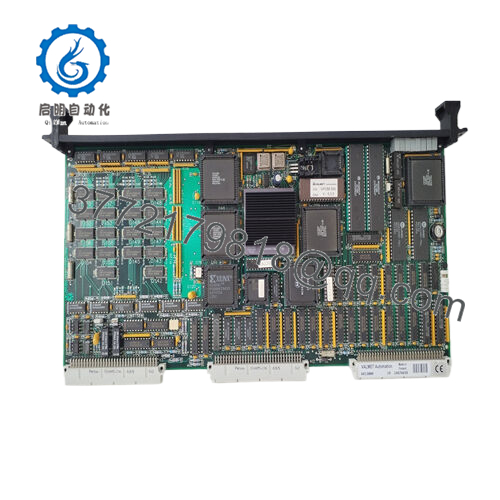

In process control systems where analog signals from field devices must be captured with unyielding accuracy to avert measurement errors or loop instabilities in rugged industrial settings, the Metso A41300 (often referenced as part of the A413 series analog input modules) emerges as a targeted ally for engineers daunted by noise susceptibility or integration hurdles in legacy PLC architectures. Envision a pulp digester in a paper mill where fluctuating 4-20 mA inputs from consistency sensors skew fiber yield, triggering off-grade sheets and waste spikes, or a mineral concentrator where voltage drift from pH probes hampers flotation control, inviting reagent overuse or tailings overflows—these pain points frequently stem from modules that falter at isolating signals amid EMI or ground shifts in shared cabinets. This analog input module counters them by converting eight channels of current or voltage signals (0-20 mA or 0-10 V) into precise digital values with 0.1% accuracy, incorporating galvanic isolation up to 1500 V to shield against common-mode voltages, ensuring your data arrives clean and contextualized for reliable control actions without the need for external conditioners.

It holds particular value in industrial automation sectors like pulp and paper or mining, where high reliability in I/O signal acquisition anchors process optimization and minimizes variance in continuous operations. The Metso A41300 slots into Metso’s Neles or Valmet PLC nodes (e.g., DAMATIC or DNA systems), supporting modular redundancy for failover under 100 ms, so transient glitches don’t derail loops. For those scaling older Valmet setups, it accommodates 2-wire or 4-wire transmitters effortlessly, curbing the tweaks needed for signal integrity while adapting to variable field loads. In high-density process control environments, its robust design and extended temperature envelope fend off vibration or heat-induced offsets, letting you extend cabling without fidelity loss. By emphasizing isolated channel handling and diagnostic relays, the Metso A41300 fortifies system stability, empowering tighter trending and predictive management that aligns with your goals for resilient, data-driven automation without the drag of frequent recalibrations in EMI-prone landscapes.

When evaluating analog inputs for rugged architectures, the Metso A41300 merits a look for its channel versatility and noise resilience, providing the acquisition reliability that underpins efficient oversight in vibration-heavy or humid environments.

- A41300

The Metso A41300 operates as an eight-channel analog input module in the field I/O layer of Metso’s Neles/Valmet distributed control systems, digitizing 4-20 mA or 0-10 V signals from sensors into process variables for PLC processors or safety controllers. It occupies a single slot in PLC node units (e.g., via backplane in DAMATIC cabinets), where each channel features 1500 V isolation to guard against noise, supporting optional HART overlay for polling device status or alarms over the same loop—bidirectional without disrupting analog flow. This enables integration with asset management tools, where HART bursts trigger on-demand queries during normal scans.

Power-sourced from the node at 24 V DC, it communicates status and digitized values via the PLC bus, with redundancy wiring allowing a standby module to assume duties in milliseconds upon primary fault detection. It meshes with output modules like AOH4 for closed-loop feedback, handling scan rates down to 100 ms per channel while complying with Profibus for hybrid networks. Onboard diagnostics scan for wire breaks, overrange, or HART timeouts, routing alerts to consoles for targeted response, and the module’s design incorporates filtering for faster settling in dynamic processes. Nestled between field terminations and control logic, the Metso A41300 streamlines I/O architecture by consolidating inputs in compact nodes, where screw terminals ease field wiring and its EMI shielding preserves accuracy in backplane-shared setups, cultivating a fault-resilient framework that scales with protocol evolutions like Ethernet/IP without rework.

| Specification | Details |

|---|---|

| Model Number | A41300 |

| Brand | Metso (Neles/Valmet Automation) |

| Type | Analog Input Module (8-ch, Isolated) |

| Input Voltage | 24 V DC (node-supplied) |

| Operating Temp Range | -20°C to +60°C |

| Mounting Style | Backplane Slot (PLC Node) |

| Dimensions | 35 x 140 x 120 mm (W x H x D) |

| Weight | 0.25 kg |

| Interface/Bus | PLC Bus, HART (optional) |

| Compliance | CE, ISO 9001, RoHS |

| Supported Protocols | Profibus, Modbus, HART |

| Typical Power Draw | 6 W (full load) |

Opting for the Metso A41300 equips your PLC with inputs engineered for steadfast accuracy, holding 0.1% calibration across environmental swings to eliminate the fine-tuning that erodes margins in variable-load processes, ultimately sharpening control responses and curbing waste from imprecise readings like pulp density or slurry pH. This precision shines in continuous runs, where isolated channels maintain signal fidelity to prevent mechanical stress on connected sensors, extending equipment lifespan and cutting service calls in abrasive settings.

Diagnostic relays enhance maintenance efficiency too, surfacing error codes and trend data that let your team address root causes proactively, rather than reacting to failures—slashing downtime by up to 30% in well-monitored systems. The module’s slot-in design trims engineering overhead as well; with native bus mapping, adapting to evolving process needs involves simple parameter tweaks, not full reconfigurations, freeing resources for strategic tasks. Tailored for endurance in rugged zones, it buffers against surges up to 500 V, ensuring your PLC core stays insulated from field gremlins and adaptable to workflow pivots with minimal footprint creep.

In pulp refiners, the Metso A41300 aggregates temperature and pressure signals from digester probes, where its isolated channels endure steamy, fibrous atmospheres to uphold critical system uptime amid continuous operations, preventing overcooking in batch cycles.

Mining SAG mills rely on it for load cell inputs, leveraging fast-scan filtering for real-time adjustments in dusty, vibration-riddled setups, amplifying high-reliability throughput.

For water treatment clarifiers, this module ingests turbidity analogs, meeting needs for precise flocculation under wet, chemical-heavy conditions while supporting modular expansions in expansive I/O networks.

A413140 – Higher-density (16-ch) variant for expanded analog input in larger PLC nodes.

AOH4 (A413139) – Complementary analog output module for balanced I/O in Valmet systems.

IOP341 – Digital output alternative for hybrid discrete signaling in Neles architectures.

A413050 – Serial communication module for non-analog field interfaces.

IOP320 – Analog input handler for legacy Valmet PLC integrations.

Neles ND9000 – Compatible PLC node for housing the A41300 in rack builds.

Valmet DNA – Modern DCS platform for upgrading from A41300-based systems.

Before installing the Metso A41300, verify PLC node compatibility with your Valmet or Neles firmware (version 5.x or later for HART passthrough), and torque terminals to 0.5 Nm to secure connections against vibration—overtightening can stress traces. Confirm loop loads under 600 ohms per channel to avoid voltage sags, and route input cables away from power lines by 200 mm to mitigate induced noise, especially in grounded cabinets with EMI from drives.

For ongoing maintenance, inspect terminals quarterly for secure seating and cleanliness, as dust buildup can degrade signal quality in fibrous or dusty process areas. Monitor diagnostic outputs monthly via the PLC console to track trends in channel health, logging any overrange alerts for proactive fuse checks. Perform a yearly functional test by simulating 4-20 mA loads to validate linearity, and update firmware as Metso releases patches for enhanced performance or security. This approach keeps the module operating optimally without excessive downtime, supporting your team’s efficiency in managing the automation setup.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626