Description

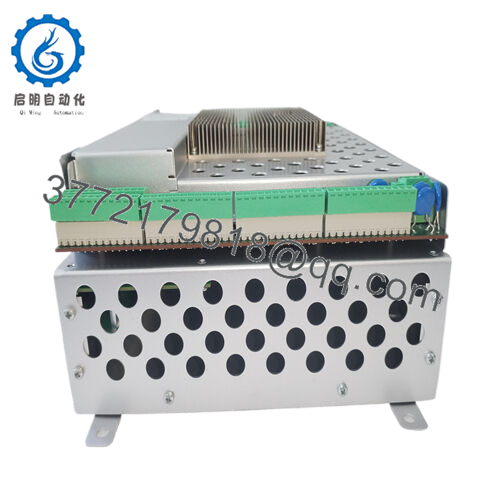

LV5F30-NF is an industrial grade controller module that plays a core control role in industrial automation systems. It is like the “brain” of the entire system, responsible for receiving data from various sensors, analyzing and processing it, and sending precise control instructions to actuators to ensure that industrial equipment runs stably according to predetermined programs.

LV5F30-NF

This module has powerful high-performance processing capabilities and is equipped with multi-core processors internally, which can support fast processing of real-time data. When faced with complex industrial data, such as operational status data of production line equipment, various parameter data in energy systems, etc., it can quickly analyze and calculate, respond in a timely manner, and ensure the timeliness and accuracy of control. Its modular design has great advantages and supports flexible customization according to specific application scenarios. Enterprises can choose different functional modules for integration based on the characteristics and needs of their own production processes, achieving personalized control solutions and greatly improving the applicability of the modules.

LV5F30-NF

Main features and advantages:

In terms of communication,LV5F30-NF is equipped with a multifunctional interface that supports various commonly used communication protocols such as RS-485 and Ethernet. This enables it to seamlessly connect with different types of devices, whether it is PLCs, sensors, or other industrial automation equipment, enabling easy data exchange and building a stable and efficient industrial communication network. The module adopts industrial grade design, with excellent anti vibration and anti-interference capabilities, and can operate stably in harsh industrial environments. Whether it is a chemical production workshop with high temperature and high humidity, or the surrounding electrical equipment with strong electromagnetic interference, it will not affect its normal operation, fully ensuring the reliability and durability of the system. In addition, this module supports user-defined programming, allowing enterprises to write personalized control programs based on their unique control needs, enabling them to flexibly respond to various complex production scenarios. It also integrates diagnostic functions, which can monitor its own operating status in real time. Once the system malfunctions, it can quickly locate the problem and handle it in a timely manner, effectively reducing downtime and improving production efficiency. At the same time, the module adopts a low-power design, which not only achieves efficient control, but also pays attention to the rational utilization of energy, achieving the goal of energy conservation and environmental protection.

Its powerful data processing capabilities and fast response characteristics enable precise control of industrial equipment, effectively improving production efficiency, reducing defect rates, and enhancing product quality. Modular design and custom programming capabilities enable enterprises to customize control solutions based on their own production needs, enhancing system flexibility and adaptability, and reducing system construction and upgrade costs.

The excellent anti-interference ability and reliability of this module ensure the stable operation of the system in harsh industrial environments, reduce equipment failures and maintenance frequency, and lower overall operating costs. Multi functional interfaces and good communication compatibility facilitate integration with various devices, helping to build a comprehensive and efficient industrial automation network. In addition, low-power design conforms to the concept of energy conservation and environmental protection in modern enterprises, and can save energy expenses for enterprises in long-term operation.

LV5F30-NF

Technical specifications:

Model Number LV5F30-NF

Brand GE

Type Controller Module

Input Power 24V DC or 110 – 240V AC

Processor Industrial – grade multi – core processor

Memory Standard DDR RAM, expandable

Storage Supports solid – state storage or external storage devices

Communication Interfaces Ethernet, RS – 485, USB, CAN bus, etc.

I/O Channels Multiple input and output channels, supporting analog and digital signals

Operating Temperature – 40°C to + 70°C

Electromagnetic Compatibility Complies with industrial – environment EMC requirements

Enclosure Material Industrial – grade protective enclosure, supporting IP65 or above protection level

Dimensions and Weight Compact design for easy system integration

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

LV5F30-NF

Application areas:

In the energy industry, it can be used for critical control tasks in wind power generation, solar energy systems, and other renewable energy systems.

In wind power plants, precise control of parameters such as wind turbine speed and pitch angle is used to achieve efficient conversion of wind energy and stable output of electricity. In solar energy systems, the working state of solar panels can be optimized based on factors such as light intensity and panel temperature to improve the efficiency of solar energy utilization.

In the field of manufacturing automation, this module can be integrated into factory automation production lines, responsible for controlling equipment and processes. In the welding, assembly and other production processes of automobile manufacturing factories, precise control of robots and various equipment ensures the accuracy and consistency of the production process, improving the quality and efficiency of automobile production.

In terms of power management, LV5F30-NF can be applied to the management and monitoring of power substations and distribution systems. By real-time monitoring of power parameters such as voltage, current, power, etc., intelligent regulation of power equipment is carried out to ensure the safe and stable operation of the power system and improve the reliability of power supply.

In the field of industrial equipment control, it can control machine tools, pumps, compressors, and other industrial machinery. In the machining workshop, precise control of the operating parameters of the machine tool is carried out to ensure machining accuracy and product quality.

In chemical production, real-time monitoring and regulation of the operating status of pumps and compressors are carried out to ensure the continuity and safety of the production process.

Related products:

LV5F20- NF – has relatively low performance and is suitable for small industrial automation scenarios with low requirements for control accuracy and data processing speed, and limited budget. For example, simple equipment control in small processing plants is cost sensitive, and LV5F20-NF can meet their basic control needs at a relatively affordable price.

LV5F40- NF – Optimized for processor performance, memory capacity, and more, capable of handling more complex and demanding industrial control tasks. For example, the automated production lines of large steel enterprises have complex equipment operation and large data processing capacity. The powerful processing capability of LV5F40-NF can ensure stable system operation and achieve precise control.

LV5F30- SF – Optimized for specific application scenarios, such as in situations with extremely high safety requirements, it may enhance fault diagnosis and safety protection functions. In industries with extremely strict safety requirements such as aerospace manufacturing, LV5F30 SF can provide a higher level of safety assurance to prevent serious accidents caused by control failures.

LV5F30- HF – Improved heat dissipation design, more suitable for operation in high-temperature environments, such as in high-temperature work scenarios in the metallurgical industry. The temperature inside the metallurgical factory is relatively high, and ordinary controller modules may experience performance degradation or even malfunction due to overheating. The LV5F30-HF’s good heat dissipation design can ensure its stable operation in high temperature environments.

LV5F30- EF – With stronger network communication capabilities, it can better integrate into large-scale industrial automation networks, achieve interconnectivity with more devices, and is suitable for building large-scale, intelligent industrial IoT systems. In the construction of smart factories, a large number of devices require real-time communication and collaborative work. The powerful communication capability of LV5F30-EF can meet this demand and promote the intelligent upgrading of factories.

LV5F30- PF – has been optimized in terms of software algorithms, further improving control accuracy and system response speed, meeting the high-end application scenarios that have the ultimate pursuit of industrial control performance. In the precision electronics manufacturing industry, there is a high demand for equipment control accuracy. The LV5F30-PF optimized algorithm can ensure high-precision control of the production process and improve product quality.

LV5F30- CF – enhances compatibility with third-party devices, making it easier for users to choose from a wider range of auxiliary devices from different brands when building systems, and reducing system integration costs. When upgrading and renovating equipment in some industrial enterprises, it may be necessary to connect new equipment from different brands. The good compatibility of LV5F30 CF can reduce adaptation issues between devices and improve renovation efficiency.

Installation and maintenance:

Before installing the LV5F30-NF controller module, engineers need to carefully inspect the installation environment. Ensure that there is sufficient space in the installation location for module installation and later maintenance, while also ensuring good ventilation in the installation location to avoid poor heat dissipation during module operation that may affect performance. Check the power supply of the system to ensure that the input voltage matches the rated voltage of the module, and prevent damage to the module due to abnormal voltage. At the same time, a comprehensive evaluation of the existing control system architecture should be conducted to clarify the communication requirements and network topology of each device, in order to plan the connection between modules and other devices reasonably. In addition, it is necessary to check whether the appearance of the module is damaged, whether the accessories are complete, and ensure that the module is in good condition before installation.

Regularly checking the status indicator lights of the module is an important part of daily maintenance. Under normal circumstances, the indicator light will display the working status of the module according to a specific mode. If there is an abnormality in the indicator light, such as one indicator light being constantly on or off, it may indicate that the module has a fault and needs to be checked in a timely manner. Every once in a while, check the connection cables between the module and other devices to ensure a secure connection, no looseness or damage, and ensure the stability of data transmission. It is recommended to conduct regular performance testing on the module, including the detection of indicators such as data processing speed and control accuracy, in order to promptly identify potential problems and optimize them. At the same time, attention should be paid to keeping the module clean and avoiding dust accumulation that affects heat dissipation and performance. A clean soft cloth can be used to regularly wipe the surface of the module.

Other GE brand product models:

GE 176449-05

GE C200/10/1/1/1/00

GE DS200CDBAG1A

GE 151X1233DB02SA02

GE IS210SAMBH1A

GE IS420UCSBH4A

GE 151X1235DB15SA01

GE DS303A3A01GXA003XF

GE DS303A3C01GXA003XP

GE IS215AEPAH1A

GE SR745-W2-P1-G1-HI-A-L-R

GE SR489-P1-HI-A20-E

GE SR745-W2-P1-G1-HI-A-L-R-E

GE SR489-P5-LO-A20-E

GE PWB68A993125

GE IS220PPROH1A

GE IS420UCSBH4A

GE IS420UCSBH1A

GE SDCS-PIN-48-COAT

GE SDCS-CON-H01

GE DS200ADMAH1A

GE DS200VPBLG2A

GE DS200DDTBG2A

GE IS415UCVHH1A

GE DS200SIOBH1ABA

GE IC695CPU315

GE SR469-CASE

GE IC754VSI06STD-KH

GE IS2020RKPSG2A

GE IS400AEBMH1AJD

GE DS200TCQCG1AJD

GE IS2020RKPSG2A

GE IC695CPU315

GE IS200EPCTG1A

GE IS200EDCFG1A

GE IS200EXAMG1A

GE IS200ERBPG1A

GE 345-E-P5-G5-H-E-S-N-N-3E-D-N

GE 1VCF750132802

GE MFAC34

GE 469-P5-HI-A20-E-H

GE 350-E-P1-G1-H-E-S-C-P-SN-D-N

GE 5266222-2 – GSCB GOC6.6

GE IS400AEBMH1AJD

GE DS200TCQCG1AJD

GE 239-RTD-AN

GE 239-RTD-AN

GE 239-RTD-AN

GE 269PLUS-100P-120VAC

GE IS420UCSBH1A

GE Physical 239 239-RTD-AN

GE VMIVME2540-300

GE 8507-BI-DP 8507-BI-DP-01

GE VMIVME2540

GE SLN042 IC086SLN042-A

GE SLN080 IC086SLN080-A

GE VMIACC-5595-208 350-805595-208N

GE SBC486DX66

GE F650 F650BFBF2G0HIE

GE VMIACC-5595-208

GE IS215WEPAH2B

GE IS210AEAAH2B

GE 239

GE 369 panel

GE IS210AEBIH3B

GE IC660EPM100J

GE VPROH2B IS215VPROH2BC

GE DS2020PDMAG6

GE IS220UCSAH1A

GE DS200TCQCG1AJD

GE IS200ECTBG1ADE

GE IS200EXHSG3REC

GE IS220PPDAH1A

GE 845-EP5M5G5HNNAANGAPBCSENWB

GE 336A5199AMP1

GE F35-C-U03-HUH-F8L-H67-M6T-PXX-UXX-WXX

GE C60-C-U03-HUH-F8L-H6U-M6D-P6D-U6T-WXX

GE HE700GEN200

GE IC697BEM763

GE 339-E-P1-G1-H-E-S-N-P-1E-D-N

GE DS3800NB1B

GE DS3800HFPB1F1E

GE IC695CPE330

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626