Description

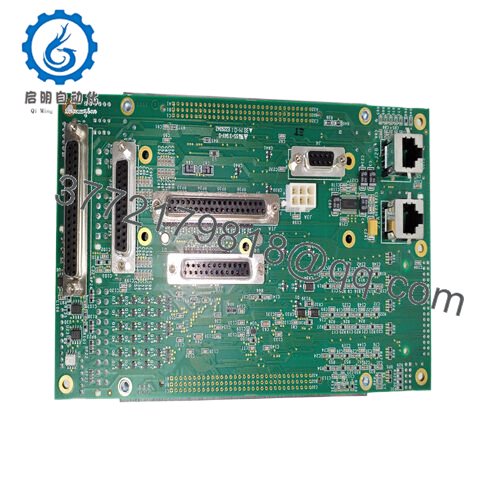

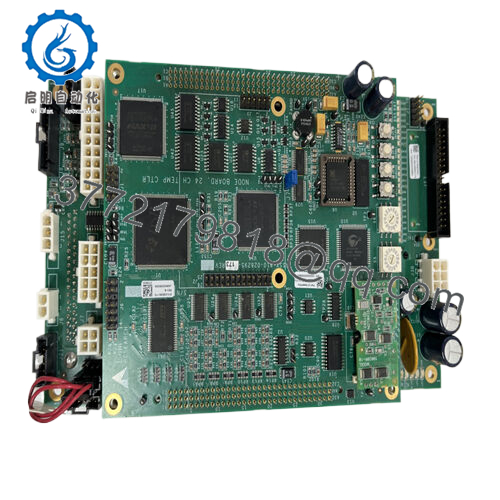

The LAM 853-049542-173 is a sophisticated industrial control module combining signal conditioning and input/output (I/O) handling, commonly used in semiconductor manufacturing and process automation environments. Designed to support distributed control systems (DCS) and programmable logic controllers (PLC), this module plays a vital role in managing sensor signals and controlling process variables across complex automation systems. Its multi-protocol communication capabilities make it adaptable to a broad range of automation architectures, contributing to precise and reliable industrial control.

Applied widely in semiconductor fabrication tools and other automated process lines, the LAM 853-049542-173 enhances system responsiveness and stability by conditioning input signals from various instruments and executing control commands to actuators and other output devices. Its role is crucial in maintaining process consistency, improving data integrity, and facilitating real-time monitoring and adjustments, which are essential for the high-yield manufacturing requirements of semiconductor fabs.

Functionally, the LAM 853-049542-173 serves as a critical interface board that enhances signal fidelity and manages communication between field devices and central control systems. It processes multiple temperature channels (typically 24), offering accurate and stable temperature control critical for maintaining optimal processing conditions. This feature is especially important in semiconductor manufacturing where thermal management directly influences product quality and throughput.

The module supports a standard 24 V DC power supply with typical consumption around 120 mA, operating reliably within a temperature range of -20°C to +60°C. Its compact design and robust construction ensure easy integration into existing control panels, while maintaining compliance with industrial standards. Users benefit from its long-term drift below 0.3%, ensuring stable performance over extended operating cycles.

The LAM 853-049542-173 boasts advanced technical specifications tailored for demanding industrial automation. Its signal conditioning capabilities include filtering, noise reduction, and isolation to protect sensitive downstream electronics. Multi-protocol communication enhances its interoperability with varied control architectures and networked environments.

- 853-049542-173

The board is engineered for durability with mechanical and electrical designs that minimize drift, noise, and signal distortion. This enhances overall system reliability and reduces error rates, ensuring accurate data processing essential in critical manufacturing processes. Its efficient power consumption and low maintenance requirements make it an economic choice for continuous operation in precision control settings.

| Parameter | Value |

|---|---|

| Model | LAM 853-049542-173 |

| Brand | LAM (Lam Research) |

| Type | Industrial Control Module (Signal Conditioning + I/O) |

| Power Supply | 24 V DC ±15% |

| Current Consumption | Typical 120 mA |

| Number of Channels | 24 Temperature Channels |

| Operating Temperature | -20°C to +60°C |

| Signal Accuracy | Long-term drift < 0.3% |

| Communication | Multi-protocol |

| Application | Semiconductor manufacturing, DCS, PLC systems |

| Dimensions | Compact PCB design |

Related modules compatible with the LAM 853-049542-173 include:

LAM 810-028295-150 / LP810-028295-173 – Complementary semiconductor control board for additional I/O management.

KOLLMORGEN S21260-SRS – Servo drive module compatible with control architectures using the LAM interface.

AB 80026-524-01-R – Gate module for commutation used alongside LAM control boards.

Motorola MVME162LX – Embedded controller module often integrated in industrial automation systems employing LAM modules.

EPRO/EMERSON PR6423/000-000 – Eddy current probe module for precise sensor input integration.

Before installation, ensure that cabinet space accommodates the LAM 853-049542-173 with proper ventilation to maintain operational temperature limits. Secure grounding and shielding of all signal and power cables should be implemented to avoid electromagnetic interference, which could degrade signal integrity.

Regular maintenance includes visual inspection of the PCB and connectors, verification of signal conditioning performance, and firmware updates to maintain communication protocol compatibility. Monitoring the board’s temperature channels for signs of drift or signal degradation helps preemptively address control system anomalies, minimizing downtime risks.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626