Description

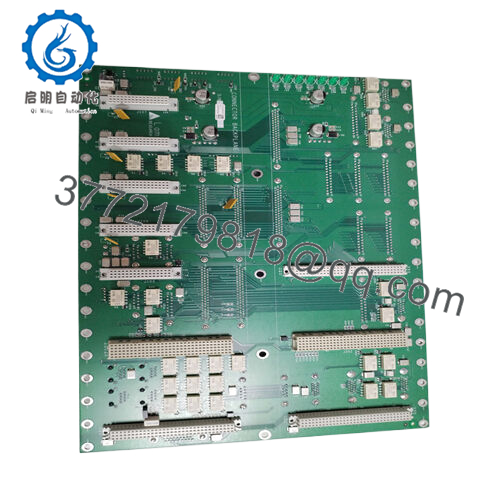

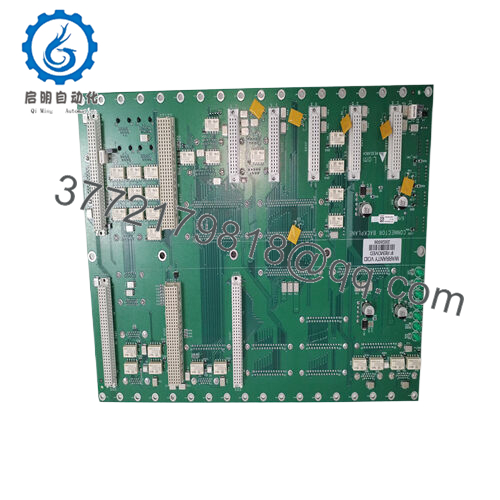

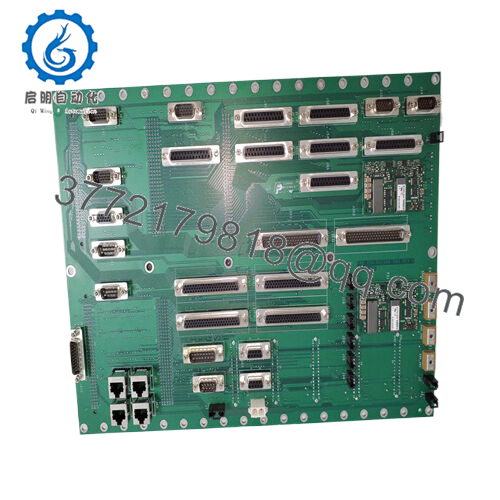

The LAM 810-072907-005 is a specialized printed circuit board (PCB) assembly designed primarily for semiconductor manufacturing equipment, specifically as part of a vacuum transfer module (VTM) or related subsystems. Its main applications involve wafer-handling sensor signals such as position sensors and vacuum pressure monitors, motor and actuator control including robotic arm movements, and safety interlock circuits like door switches and vacuum integrity checks. This board acts as an interface or breakout board, facilitating signal routing, power distribution, and communication between the VTM and other tool modules.

Typically installed in cluster tool VTMs, like the Lam 2300® and Lam 9400® series, the LAM 810-072907-005 plays a critical role in enabling the transfer of wafers between processing chambers in a high-vacuum environment. It is engineered to meet the demanding precision and reliability needs of semiconductor fabrication, where maintaining vacuum integrity and precise control over transfer mechanisms is essential for process quality.

Functionally, the LAM 810-072907-005 operates within the larger cluster tool automation framework by enabling precise sensor and actuator interface management. It supports high-density wiring configuration, ensuring compact and efficient signal management on the board. The assembly is lightweight and thin, combining hard and flexible circuit board materials to withstand physical stress while maintaining signal integrity.

- 810-072906-005

As part of a highly integrated semiconductor process system, the LAM 810-072907-005 facilitates real-time control and communication, supporting rapid response from sensors and actuators to maintain the controlled environment and safe wafer transfers. It is widely appreciated by engineers for its compatibility with legacy and modern cluster tool sets, enabling smooth replacements or upgrades without disrupting operational workflows.

The technical strengths of the LAM 810-072907-005 PCB breakout board include its high wiring density, durability, and versatility in signal and power management. Its design allows for efficient bending and adaptation to constrained installation spaces without compromising electrical performance. The precise construction balances light weight with mechanical robustness, critical in semiconductor tools that require minimized vibrations and shock absorption.

The board supports crucial safety interlock circuits to prevent operation anomalies, protecting both personnel and delicate equipment. Furthermore, the LAM 810-072907-005 ensures reliable vacuum pressure monitoring and sensor signal accuracy, crucial to maintaining process chamber conditions. Its role in power distribution helps stabilize voltages and keep connected modules functioning at peak performance.

Engineers benefit from the straightforward integration of this module into established semiconductor fabrication lines, supported by comprehensive technical documentation and compatibility with standard cluster tool architectures.

| Parameter | Value |

|---|---|

| Model | LAM 810-072907-005 |

| Brand | LAM Research |

| Type | Vacuum Transfer Module Breakout PCB |

| Application | Wafer handling, sensor interfacing, actuator control |

| Compatible Systems | Lam 2300®, Lam 9400® series cluster tools |

| Wiring Density | High |

| Board Material | Hard and flexible PCB combination |

| Dimensions | Compact, slim profile |

| Weight | Lightweight |

| Key Functions | Signal routing, power distribution, safety interlocks |

| Operating Environment | High-vacuum process tools |

Related modules often paired or compatible with the LAM 810-072907-005 include:

LAM 810-072907-006 – Alternative breakout board variant with extended signal handling capabilities.

LAM 810-072900-001 – Sensor interface PCB used in similar vacuum transfer process modules.

LAM 810-085254-002 – Power distribution board complementing the breakout board in cluster tools.

LAM 810-081451-005 – Safety interlock control board used in semiconductor process equipment.

LAM 810-072900-005 – Advanced actuator control interface module.

During installation, ensure that the LAM 810-072907-005 is securely mounted within the vacuum transfer module enclosure with sufficient clearance for air circulation and cable management. Proper grounding is critical to maintain signal integrity and minimize electromagnetic interference. Careful connection to sensor and actuator wiring, following the cluster tool’s wiring schematics, is essential to prevent signal loss or malfunctions.

Maintenance routines should include periodic visual inspection for signs of wear, corrosion, or loose connectors, especially due to the vacuum environment. Regular functional testing of sensors and interlock circuits facilitated by this board helps catch early faults. Firmware or control system software should be kept up to date to maintain optimal communication and control responsiveness.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626