Description

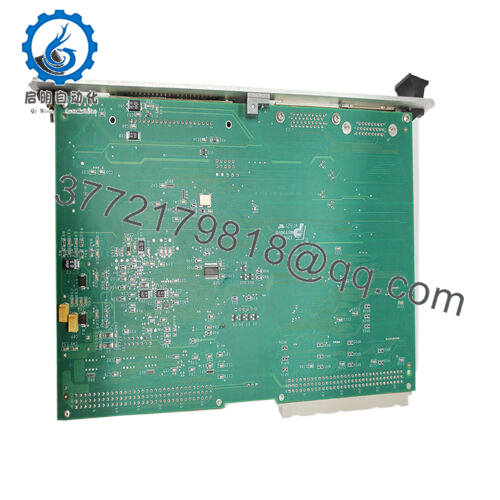

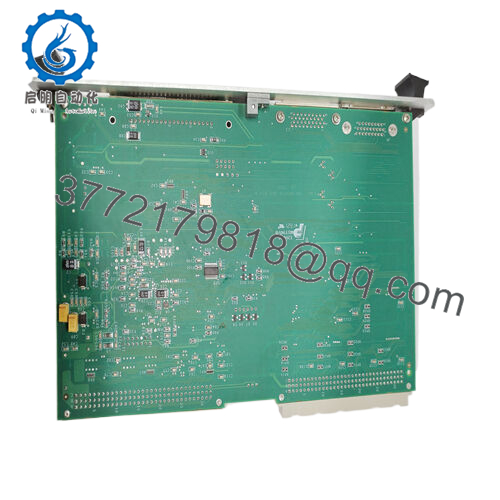

The LAM 810-068158-014 is a critical semiconductor industry module serving as a node robot interface PCB used extensively in precision automation and robotics within semiconductor fabrication equipment. This board facilitates vital communication and protocol processing between robot control systems and semiconductor manufacturing tools, ensuring seamless coordination for wafer handling and process automation. It is engineered to meet the stringent reliability and speed demands of modern semiconductor production environments, where precise timing and signal management are paramount.

Commonly integrated in advanced cluster tools and fabrication modules, the LAM 810-068158-014 handles control plane functions such as protocol routing, service processing, and forwarding control, making it indispensable in maintaining high throughput and minimizing process interruptions. Its design reflects industry standards for high-frequency operation, typically around 50 kHz, and it is CE certified for quality and safety compliance.

Functionally, the LAM 810-068158-014 operates as a node interface that processes communication protocols and manages routing within automation systems, particularly for robotic actuators and sensors. It implements sophisticated service processing features, facilitating real-time data exchange essential for process synchronization and fault management. This module fits within broader control architectures relying on distributed control and networking technologies, providing key interoperability and data handling support.

The board’s compatibility with existing semiconductor equipment architectures allows engineers to seamlessly replace or upgrade node interface components without disrupting complex system workflows. It is known for its reliable operation under consistent load conditions and supports high-frequency signal processing critical for maintaining accuracy and responsiveness in semiconductor robot operations.

The LAM 810-068158-014 boasts advanced technical attributes, including support for a typical operating voltage of 220 V and handling high-frequency control signals up to 50 kHz. Constructed with high-quality electronic components, it ensures stable and efficient protocol processing critical for automation reliability. The module’s compact design facilitates easy mounting and integration within control cabinets or robotic tool assemblies.

Durability and long-term reliability are key features, with the board designed to operate continuously in demanding manufacturing environments without performance degradation. The CE certification confirms its adherence to strict regulatory standards, enhancing confidence for global semiconductor customers. Its relatively lightweight construction, approximately 0.35 kg, complements automated tool designs where weight and space optimization are essential.

- 810-068158-014

| Parameter | Value |

|---|---|

| Model | LAM 810-068158-014 |

| Brand | LAM (Lam Research) |

| Type | Node Robot Interface PCB |

| Operating Voltage | 220 V |

| Frequency Range | Up to 50 kHz |

| Certification | CE Certified |

| Weight | Approx. 0.35 kg |

| Function | Protocol processing, routing, service management |

| Application | Semiconductor automation, robotic control systems |

| Dimensions | Compact PCB design |

Related or compatible modules include:

LAM 810-068158-013 – A closely related PCB interface board sharing similar protocol and routing functionalities.

LAM 810-073479-215 – Circuit board module designed for enhanced system monitoring functions in semiconductor fabrication.

810-466-015-010 VIOP III Board – A VME bus-based module for data transmission and control used alongside node interfaces.

605-A53842-002 Processor CPU Module – High-performance processor module often integrated with interface PCBs for comprehensive control.

JTS Mstg&optimus 810-073479-215 – Complementary circuit board modules for system optimization in semiconductor equipment.

Installation of the LAM 810-068158-014 demands careful integration within semiconductor tool control cabinets, considering optimal physical fit and secure board mounting to prevent mechanical stress. Proper electrical grounding and shielding methods must be observed to ensure signal integrity and compliance with electromagnetic compatibility standards.

Routine maintenance includes inspection of connectors and solder joints, validation of data routing and processing functions, and firmware or software updates when applicable to maintain enhanced protocol compatibility and security updates. These practices help sustain high uptime and precision in semiconductor production lines.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626