Description

What This Product Solves

In the fiercely competitive arena of semiconductor manufacturing and industrial process control, coordinating the precise motion of robotic arms, wafer stages, and chamber doors in plasma etch tools is a make-or-break factor—especially in Lam Research platforms like the TCP 9600 or Vector series, where even a 50ms lag in stepper positioning can misalign wafers, etch features off-spec by nanometers, and cascade into yield-killing defects that halt production lines and rack up scrap costs exceeding $10k per lot in fabs gunning for 3nm nodes. These precision demands intensify during high-throughput runs or tool quals, where vibration from vacuum pumps or EMI from RF sources induces jitter in control signals, forcing operators to dial back speeds or insert manual overrides that erode efficiency and inflate cycle times under the relentless pressure of SEMI E10 uptime metrics and escalating cleanroom energy bills.

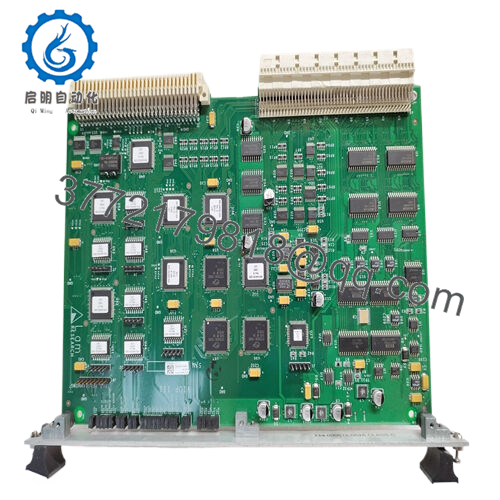

The Lam Research 810-046015-010 steps in as the PCBA VIOP III Board (VIOP-3), a specialized interface controller engineered to orchestrate stepper motor drives and I/O synchronization in Lam’s etch ecosystems, delivering sub-millisecond command fidelity that keeps wafer trajectories on track without the dropouts that undermine plasma uniformity. It’s essential in retrofits for legacy 300mm etchers or expansions into multi-chamber clusters, where modular integration requires drop-in PCBs that mesh with GEM/SEMI protocols without backplane overhauls. For engineers battling high-reliability hurdles in industrial automation for wafer processing, this board intervenes when off-the-shelf motion controllers can’t tame the torque ripples from multi-axis steppers or filter noise in discrete feedback loops, ensuring I/O signal integrity across corrosive, high-vibe environments.

Visualize a deep reactive ion etch (DRIE) cycle where the VIOP must pulse three-axis steppers to shuttle masks under 500W bias fields, or a contact clean where door interlocks demand glitch-free polling to avoid particle bursts—the Lam Research 810-046015-010 dominates, with its embedded drivers and fault latching that preempt stalls before they scar substrates. In these semiconductor process control infernos, it slashes the diagnostic drag of kinematic faults, streaming status to the tool HMI for proactive pauses. At heart, this VIOP board reimagines motion mastery as a margin multiplier, not a misalignment menace—empowering the throughput and defect control that fortifies fabs, while paving the way for scalable robotics in your etch evolution where every step spells silicon supremacy.

How the Product Works & Fits into a System

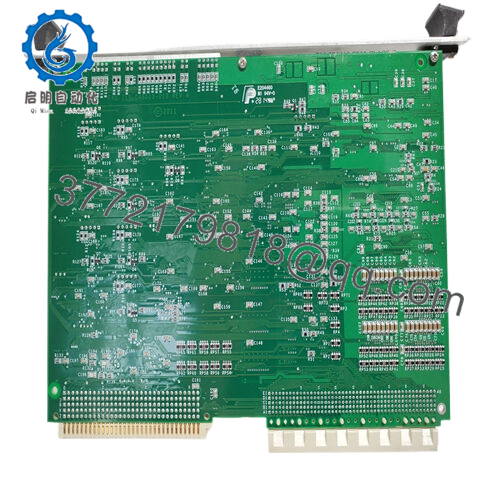

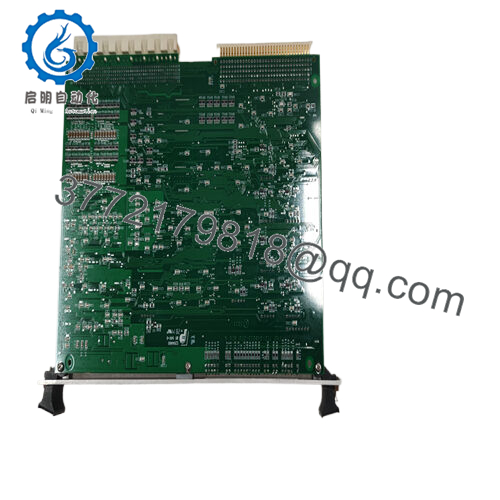

The Lam Research 810-046015-010 operates as the motion nexus in Lam etch tool architectures, harnessing a microcontroller core to decode serial commands from the system CPU over RS422 links, then driving up to three bipolar stepper motors via PWM chopper circuits that deliver 2-5A phases with microstepping resolution down to 1/64th—yielding positional accuracy within 0.1° while monitoring stall currents through back-EMF sensing, all powered by a 24VDC rail with onboard isolation to shrug off 1kV transients from plasma arcs. It executes trajectory profiles stored in onboard EEPROM, interpolating linear/circular paths at 10kHz rates, and interfaces discrete I/O for limit switches or encoders, latching faults on overtemp or lost steps to trigger e-stops without recipe resets.

Positioned in the robotics and I/O layer of your tool’s control stack, it slots into a Eurocard backplane via DIN 41612 edges, connecting upstream to the GEM host via fiber optics for 100m reach and downstream to stepper coils through screw terminals—optimized for redundant setups where shadow boards mirror axes for failover in <20ms, preserving alignment during handler swaps. Protocol fluency includes Lam’s proprietary VIOP dialect with SEMI E5 overlays for fab automation, configurable via the tool console to tune accel/decel ramps for process-specific payloads like 300mm carriers.

- 810-046015-010

Diagnostics are etched-in: seven-segment displays for axis status and error queues, plus a JTAG port for firmware flashes that capture step traces, enabling field debugs without chamber downtime—no logic analyzer required. In a holistic hierarchy, it bridges the motion controller upstream and field effectors downstream, crafting a choreographed chain for flawless wafer ballet—like in a TCP transformer coupled plasma etch where it sequences electrostatic chuck clamps with stage slews to center beams. For a Vector Premier retrofit, the Lam Research 810-046015-010 would harmonize loadlock transfers, compensating for thermal expansions in rails to sustain <1µm repeatability. This innate interlocking trims homing rituals, framing it as the adroit axis in your automation arabesque, fusing command cadence with coordinate clarity for attuned, aberration-free action.

| Specification | Details |

|---|---|

| Model Number | 810-046015-010 |

| Brand | Lam Research |

| Type | PCBA VIOP III Board (Stepper Interface) |

| Input Voltage | 24 VDC |

| Operating Temp Range | 0°C to 50°C |

| Mounting Style | Eurocard Backplane / DIN 41612 |

| Dimensions | 6 x 4 x 0.6 in (160 x 100 x 15 mm) |

| Weight | 0.5 lb (0.23 kg) |

| Interface/Bus | RS422 Serial / Discrete I/O |

| Compliance | SEMI E5, CE, RoHS |

| Supported Protocols | Lam VIOP, SEMI E5/GEM |

| Typical Power Draw | 15 W (with motors) |

Real-World Benefits

Bringing the Lam Research 810-046015-010 into your Lam tools equips them with a VIOP board tailored for the unremitting rhythm of etch endurance, where its microstepping finesse and stall detection clamp positioning errors to <0.05mm—translating to via depths varying <2nm across fields, empowering tighter pitch rules that boost transistor density without the alignment audits that legacy drivers demand. This sharpness isn’t sporadic; it sustains through cycles, enabling high-speed slews where axis blends adapt to wafer bow, distilling defect budgets into pristine patterns across marathon masks.

Etch crews count on its fault-forwarding fabric, as back-EMF thresholds and I/O audits surface motor drags in the tool ledger—picture a shift lead preempting a stage skip from coil wear, recalibrating mid-qual sans alignment aborts. The board’s backplane affinity lightens integration loads, with edge-for-edge swaps that align with TCP chassis sans signal reroutes, hastening tool teardowns in yield-yield fabs where nanoseconds net nodes. Over fab lifetimes pushing 7 years, it cements performance constancy with a MTBF surpassing 200,000 hours, its conformal-coated circuits repelling Cl2 vapors in pump bays, so your motion mandates mature without the mire of recurrent rehomes.

Wider, the Lam Research 810-046015-010 greases growth by exposing aux GPIOs for end effectors, layering in vision where step pulses sync with metrology grabs—easing the stride to EUV reticles without axis overhauls. These fused frugalities reposition VIOPs from a velocity vise to a velocity vanguard, paring total etch expenditures while heightening the precision that propels your semiconductor pinnacle.

Typical Use Cases

The Lam Research 810-046015-010 thrives in transformer coupled plasma etchers like the TCP 9600, edging into backplanes to pulse three-axis stages for feature scaling, where its 10kHz interp holds amid 1.8GHz fields and Ar/Cl2 mixes—core to process control environments trenching gates below 10nm, shoring critical system uptime through load-unloads or fault flushes in 5nm SoC fabs. In these halogen-hazed hives, its stall sensing steels signal reliability, provisioning homing surety that averts fenceposts and CD skews.

Dielectric etch modules enlist it for STI patterning, driving electrostatic chuck tilts and focus rings under 300W bias and O2 pulses, fostering continuous uptime where fast data cycles from interferometers dictate depth uniformity. Harsh fluorocarbon films and vibe from turbo pumps probe its poise, yet it proffers unswerving strides for seamless facet fills.

In metal hardmask removal clusters, the Lam Research 810-046015-010 choreographs Vector wafer flips, syncing door actuators with robot arms over discrete loops—pivotal for used in Cu damascene where axis acuity forestalls slivers and resistance rises. Across TCP etching, contact patterning, and interconnect stripping sectors, this VIOP vitalizes applications craving coordinated kinematics in corrosive cauldrons, transmuting step surges into scaffolds of sub-nm success.

810-046015-011 – Updated VIOP with extended microstepping for finer 450mm handling.

810-234640-312 – Chamber mux companion for I/O-expanded etch stacks.

810-800081-022 – P2MB PCB tie-in for mainframe motion bridging.

810-102361-222 – Analog chamber interface for sensor-synced stepping.

810-066590-004 – 3-axis stepper driver add-on for torque-heavy axes.

810-072903-004 – Legacy VIOP variant for pre-300mm retrofits.

810-082745-003 – Edge detector junction for alignment-integrated motion.

Before seating the Lam Research 810-046015-010 in your Eurocard slot, equilibrate its EEPROM profile with the tool CPU via the console—mismatch maps can loop axes at init, stranding your stages in safe limbo. Palpate the DIN fingers for oxide or bends from storage; a contact cleaner and resistance read under 0.05Ω thwarts torque twitches that mimic load jams. Ventilation merits a slot spacer in dense subracks to vent the 15W, notably in enclosures north of 45°C where RF heat harmonics—simulate your axis loading to confirm. Pre-drive the coils with a scope at 2A phases, nailing <1% ripple sans resonance, and ground the frame tab uniquely to shunt ESD from cassette pods.

In the fab, nurture nods to foresight over fiddling. Biweekly HMI logs for step counts—clean trajectories sans stalls signal synchrony, but deviations divine a rail wear with a dynamometer. Quarterly edge ejections with ESD cuffs and alcohol ablutions on pins banish flux films from humid idles; re-dock at 0.6 Nm to buck pump pulses. Annually, barrage with profile scripts via JTAG to attest 99.99% fidelity across payloads, hoarding harmonics for homing hints. If skips surface, harness Lam’s remote trace harvester over secure RS422, but these throbs turn the Lam Research 810-046015-010 into a stride savant, routing resolve to runes over resets.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626