Description

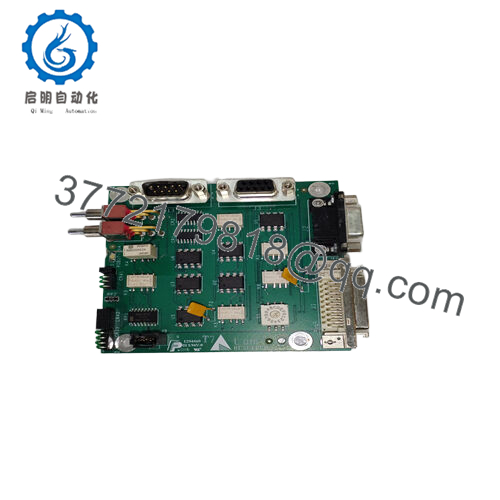

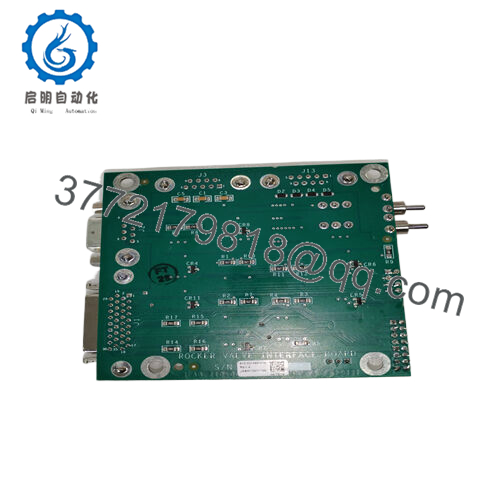

Product Model: 810-001489-016

Product Brand: LAM Research

Product Series / Role: Rocker Valve Interface Board / Interface PCB

Product Features:

- Interface board built for rocker valve control in LAM systems (often termed “rocker valve interface board”)

- OEM part for LAM Research / process tool environments

- Offered by parts houses with short-term warranties (e.g. 3 months)

- Uses standard printed circuit board (PCB) construction; available in “new,” used, and “as-is” states

Applications & Industry Context

In semiconductor or vacuum processing equipment, precise control of valves (gas, vacuum, exhaust lines, purge lines) is essential. LAM Research tools often include rocker valves—mechanical actuators that “rock” open/closed to regulate flows. The LAM 810-001489-016 board is the interface circuitry between control logic (PLC, FPGA, or system controller) and these rocker valve actuators.

Field engineers typically find this board in the valve control cabinet or module rack. When a rocker valve misbehaves or becomes unresponsive, it’s a known troubleshooting path to replace the 810-001489-016 interface board. Because many modules around it depend on its proper function, its contact with other modules or signal buses is critical.

In tool maintenance, boards like 810-001489-016 are often stocked as spares and swapped during preventive maintenance. Replacement restores valve control behavior without disturbing upstream or downstream modules.

Given the exposure to valves and potential for harsh process environments (vibration, thermal cycling, electromagnetic noise), the interface board must be robust and tolerant of industrial stresses.

- 810-001489-016

Product Role & System Fit

The 810-001489-016 is primarily a valve interface / control board. In system context:

- The board sits between the process control logic (PLC, motion controller, logic card) and the actual rocker valve actuator (solenoid, motor, driver, etc.).

- It receives command signals (open/close, valve percentages) and returns status feedback (position, fault, open/closed limit).

- It may incorporate protective circuits—e.g., current limiting, overvoltage suppression, filtering, transient protection.

- It likely connects onto a backplane or module bus, or via discrete connectors to system wiring.

- Its existence is essential: if it fails, the rocker valve commands may be lost, valves may get stuck, leading to process faults or tool downtime.

Because the board is often custom to a tool generation, compatibility with connector pinouts, voltage domains, and signal logic (e.g. TTL, ± signaling, relay drive circuits) is critical. A mismatch can lead to damage or erratic valve behavior.

Many parts houses list it as a “PCBAROCKER VALVE INTFC BDI CE” board—indicating it is the “Rocker Valve Interface Board / BDI / CE variant.”

Technical Features & Benefits

Here’s what available sources and logical inference suggest about 810-001489-016:

1. Interface / Control Board for Rocker Valves

The board is sold in listings as “Rocker Valve Interface Board.” For example, SemiconStore lists “LAM Research 810-001489-016 Rocker Valve Interface Board.” RockssAutomation sells it as a “Rocker Valve Interface Board” and offers a 3-month warranty.

2. OEM / Original Part

Multiple sellers present it as an original LAM Research part, not aftermarket.

3. Warranty / Condition Options

Some suppliers offer 3-month warranties on used boards. Conditions vary: “used,” “as-is,” or tested. J316Gallery lists a board in “parts” condition for 810-001489-016.

4. Spare / Hard-to-Find Part

PLC-module notes that 810-001489-016 is a module that is “not easy to find”, underlining scarcity.

5. Pricing Range

SemiconStore lists the used board at US$250. Some new listings (eBay) quote much higher amounts.

From a benefits view: retaining or stocking a working 810-001489-016 enables fast valve control restoration without having to redesign or rewire. Because valves are safety or flow-critical, its proper function ensures process stability.

Technical Specifications Table

Below is a speculative / aggregated spec summary based on public listings and engineering inference. Use this as a starting point, not definitive values.

| Parameter | Value / Description | Notes / Source |

|---|---|---|

| Board Type | Rocker Valve Interface Board / PCB | As listed in multiple sources |

| OEM Maker | LAM Research | Stated in all listings |

| Part Number / Model | 810-001489-016 | Primary identifier used in listings |

| Condition Options | New, Used, As-Is | Sellers list all these variants |

| Warranty | 3 months (in some listings) | RockssAutomation offers 3-month warranty |

| Price (Used) | ~US$250 | SemiconStore listing |

| Application | Valve / actuator control in LAM tools | Described as interface for rocker valves |

| Supply / Interface Domain | Likely logic-to-actuator domain (voltage drive, feedback loops) | Inferred from function as interface board |

| Market Scarcity | Rare / hard to find | PLC-module calls it “not easy to find” |

Because I did not find a full datasheet or electrical spec sheet in public sources, details like input voltage, current capability, connector pinouts, signal types (digital, analog, relay driver), isolation rating, or thermal behavior remain unknown.

Installation & Maintenance Insights

Here are field-proven tips and best practices when working with 810-001489-016:

- Board Seating & Alignment: Ensure connectors mate fully and firmly. Loose mating or slight misalignment can cause intermittent faults in valve signals.

- Power Off During Insertion / Removal: Unless your system supports hot-swap, always power down the valve control domain before swapping the board to avoid surges or damaging connected actuators.

- Wiring / Signal Polarity: Identify control input signals (e.g. open/close commands) and output driver lines. Mistakes in wiring polarity or reference ground can lead to damage.

- Shielding / Grounding: Valve interface lines can be susceptible to noise. Use shielded cables, and apply single-point grounding to avoid ground loops.

- Testing / Commissioning: After installation, step through valve commands (open, close, partial) under manual control, verify position feedback lines (if present), and observe board diagnostics. Confirm that every channel functions.

- Monitor for Heat / Drift: In continuous service, monitor board temperature and response stability. If valves respond sluggishly or feedback signals drift, the board or connected hardware may be marginal.

- Spare Board Strategy: Keep a known-good 810-001489-016 spare, prewired or ready for quick swap. Because it’s a relatively rare part, being able to drop it in can save hours of downtime.

- Burn-In / Pre-Test: Before putting into service, power the board with dummy loads to drive all output channels for an extended period (e.g. 24 hours) to catch weak solder joints or marginal components.

- Inspect Connectors and Contacts: At maintenance intervals, visually inspect connectors, clean contacts, reseat boards, and check for signs of oxidation, wear, or mechanical fatigue.

- Signal Diagnostics: If your system supports monitoring, watch for error flags, stagnation in valve response, or repeated retries. These often flag hardware interface issues.

From hands-on experience: valve interface boards are often the first suspect when a group of valves stop responding. A single board failure can incapacitate multiple zones, so careful spares planning and diagnostic tools are important.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626