Description

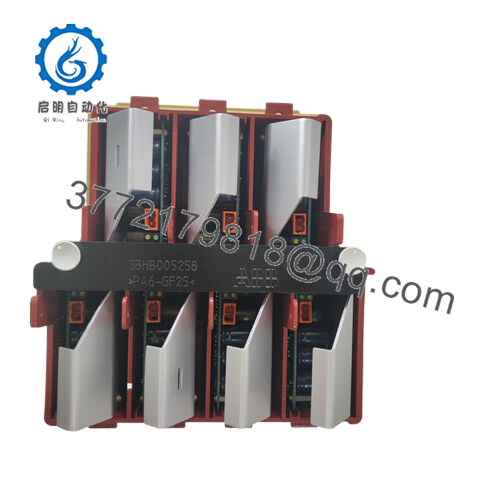

KUC711AE101 3BHB004661R0101 Product Description:

KUC711AE101 3BHB004661R0101 is a six axis industrial robot controller and the core of ABB’s IRC5 robot system, which is a leading platform for flexible automation. As the ‘brain’ of the robot system, it processes sensor data, executes motion algorithms, and communicates with higher-level manufacturing execution systems (MES). As part of the scalable architecture, it supports independent robots and complex multi robot units, where synchronous motion of up to four robots is crucial for tasks such as aircraft wing assembly.

KUC711AE101 3BHB004661R0101

Engineers value its dual core processing capability, which separates safety critical tasks such as emergency stop from conventional motion control, ensuring compliance with ISO 10218-1:2011 (Robot Safety Standard). System integrators appreciate its plug and play compatibility with ABB’s full range of robots (such as IRB 120, IRB 6700), which can reduce programming time by up to 50% compared to general-purpose controllers. Whether it’s renovating old production lines or deploying state-of-the-art collaborative robot units, KUC711AE101 3BHB004661R0101 can provide predictable performance within a payload range of 3 kilograms to 800 kilograms.

KUC711AE101 3BHB004661R0101

Main features and advantages:

precision motion control

Thanks to ABB’s TrueMove and QuickMove technologies, this controller achieves a path accuracy of ± 0.02 millimeters, which is crucial for applications such as laser welding or medical equipment assembly. Its 64 bit floating-point processor executes 100 million instructions per second, enabling real-time trajectory optimization even at maximum speed (some robot models are 20 meters per second). For high mix production environments, the Rapid programming language of the controller supports dynamic recipe changes, allowing tool changes and program switching within<30 seconds.

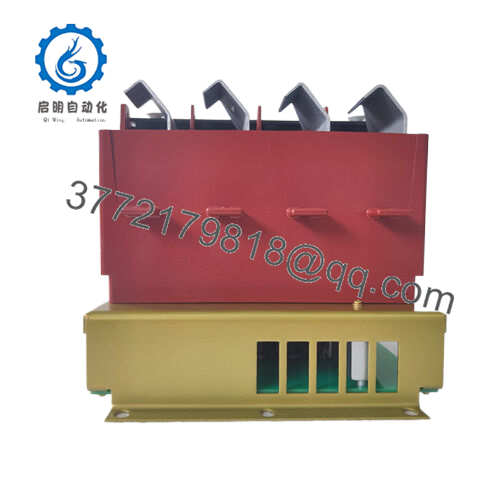

Industrial grade durability

The controller adopts an IP54 protection level housing, which can prevent dust, oil mist, and occasional water splashes, and is suitable for foundries, food processing plants, and pharmaceutical facilities. Its wide input voltage range (200-500 VAC) and built-in surge protection (1.2/50 μ s waveform) ensure stable operation in areas with unstable power grids. The thermal model predicts a service life of 10 years at full load, with an average time between failures (MTBF) exceeding 100000 hours – an important indicator for 24/7 production lines.

Future oriented connectivity

This controller has Ethernet/IP, Profinet, and OPC UA interfaces and can be integrated with ABB Ability ™ Integrate seamlessly with IIoT platforms to achieve remote diagnosis, comprehensive equipment efficiency (OEE) tracking, and predictive maintenance. Its built-in web server allows engineers to monitor the health status of robots through any browser, while API access allows developers to create custom dashboards for real-time cycle time analysis. The controller also supports SafeMove2, a set of safety features that dynamically limit robot speed when personnel enter the workspace, enabling collaborative robot operations.

KUC711AE101 3BHB004661R0101

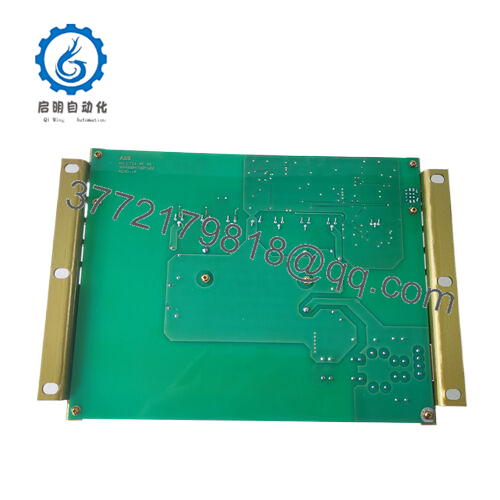

Technical specifications:

Model KUC711AE101 3BHB004661R0101

Brand ABB

Type Six Axis Robot Controller

Power supply 200-500 VAC, 50/60 Hz

Working temperature: 0 ° C-45 ° C (Extended model: -20 ° C-60 ° C)

Installation method: Wall mounted/rack mounted

Size 600 x 450 x 200 millimeters

Weight 25 kilograms

Supports 6 axes (expandable to 16 through external axes)

Communication interfaces Ethernet/IP, Profinet, RS-485, USB 2.0

Safety standards ISO 10218-1, IEC 61508 (SIL 2), ISO 13849-1 (PLd)

Programming languages ABB Rapid and RobotStudio ®

Protection level IP54, IEC 60068-2-6 (vibration: 2 g)

Contact Us

Mobile:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

KUC711AE101 3BHB004661R0101

Application areas:

In the high-risk environment of industrial robots, the KUC711AE101 3BHB004661R0101 controller is the core for achieving precision automation in manufacturing, logistics, and advanced assembly lines. Automotive original equipment manufacturers (OEMs) use this controller to manage robot welding units, which can coordinate up to 16 axes of motion with sub millimeter level accuracy, ensuring seamless welding of complex vehicle frames. For example, in a first tier supplier’s factory, the controller drives a six axis robot to spot weld electric vehicle battery casings, processing over 50000 parts per day while complying with the ISO 17652 welding standard.

In the field of electronic manufacturing, KUC711AE101 3BHB004661R0101performs well in micro assembly applications, such as placing passive components of 01005 size on printed circuit boards (PCBs) with nanometer level precision. The semiconductor packaging production line relies on its deterministic control to operate surface mount machine robots, which process precision chips at a placement speed of over 200 times per minute, minimizing damage to each component worth thousands of dollars. The controller is capable of real-time interface with visual systems (such as Cognex In Sight) to achieve adaptive path correction, which is crucial for compensating for thermal expansion or mechanical wear during 24/7 operation.

Heavy industry also benefits from its robust performance: in steel mills, the controller manages robotic arms and uses high-resolution cameras to inspect surface defects of hot-rolled steel beams. Despite the ambient temperature exceeding 400 ° C, the advanced thermal design of the controller ensures stable operation and immediately triggers shutdown in the event of cooling system failure – a feature that reduces unplanned downtime for a large steel producer by 40%.

KUC711AE101 3BHB004661R0101

Related products:

KUC701AE101- entry-level controller, suitable for small robots (payload ≤ 20 kg), does not support multi robot coordination.

KUC720AE101- High performance model, suitable for heavy-duty robots (such as IRB 8700), supports 24 axes and 1 Gbps Ethernet.

DSQC 652- I/O board (16 DI/16 DO), used to connect sensors/actuators to KUC711AE101.

DSQC 663- Servo Motor Drive Module, compatible with ABB’s permanent magnet motors.

IRC5 Pendant – Handheld programmer with touch screen, pre configured for KUC711AE101 parameter adjustment.

3HAC029976-001- Security Options Kit, used to enable SafeMove2 functionality in collaborative applications.

3BHB005561R0101- Power Distribution Unit (PDU), used for multi controller setup to ensure stable power supply.

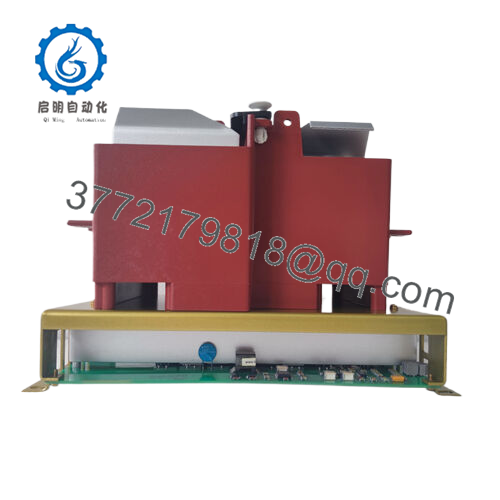

Installation and maintenance:

Precautions before installation:

Ensure that the installation surface can withstand a weight of 50 kilograms (controller+cable), and it is recommended to use shock-absorbing pads in high impact environments.

The motor power cord should be kept at least 30 centimeters away from the Ethernet/USB cable to avoid data errors caused by electromagnetic interference.

Using RobotStudio ® The software pre configures robot kinematics and safety zones before physical debugging, reducing on-site setup time by 60%.

Maintenance Guide:

Clean the air filter with compressed air of ≤ 5 bar every quarter to prevent dust from affecting the heat dissipation efficiency.

Check the connector pins annually for corrosion, especially in humid environments; Apply conductive grease to the power terminals.

Update firmware every six months through ABB online support tools, including performance optimization and integration with the new version of RobotStudio ® Compatibility patches.

For multi shift operations, arrange preventive maintenance during planned downtime periods (such as holidays), proactively replace electrolytic capacitors, and extend the lifespan of controllers.

Other ABB product models:

ABB PM861AK01 3BSE018157R1

ABB PM633 3BSE008062R1

ABB Al630 3BHT300011R1

ABB 3BHL000986P3003 5SDF1645L0006

ABB 3BHB004744R0010

ABB 3BSE023732R1

ABB PU519 3BSE018681R1

ABB PM877 3BDH000777R1

ABB 83SR51R1210 GJR2396200R1210

ABB AO2000 LS25

ABB 1SDA053999R1

ABB CI854BK01 3BSE069449R1

ABB DI830 3BSE013210R1

ABB PM645B

ABB 3BHE035301R0001 UNS 0121 A-Z,V1

ABB 3BHE035301R1002 UNS 0121A-Z,V1

ABB AO810V2

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101

ABB XVC517AE10 3BHB004744R0010

ABB UFC760BE1042 3BHE004573R1042

ABB UFC760BE141 3BHE004573R0141

ABB NAVIGATOR 600 V20

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626