Description

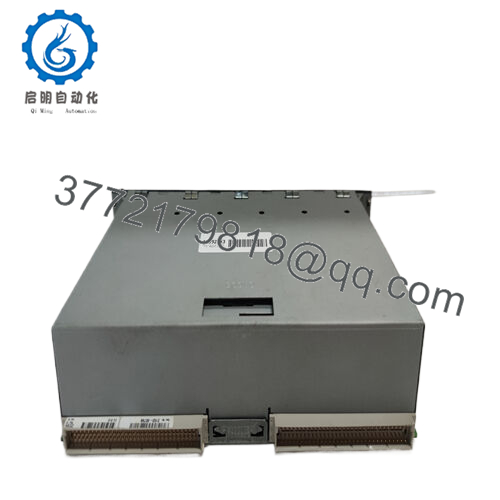

The KEBA CU313A is an industrial control module widely applied in automation sectors such as manufacturing processes, packaging machinery, and material handling systems. It is highly valued where reliable and precise control of automated equipment is essential, supporting industries like automotive, electronics assembly, and general factory automation. The module is designed to handle complex control tasks and interface with servo systems, robotics, and various industrial drives, providing real-time control and high-speed processing.

The CU313A functions primarily as a programmable logic controller (PLC) unit with robust communication capabilities and I/O management, enabling effective integration within broader automation systems. It fits in with automation architectures where modularity and scalability are critical, working alongside servo amplifiers (like FANUC A06B series) and compatible I/O modules, facilitating flexible system expansion. For industrial engineers, its ability to interface with diverse industrial hardware enhances system versatility and operational efficiency.

- CU313A

Outfitted with a rated voltage of 220V AC and operating at a frequency of 30 kHz, the CU313A features compact dimensions of 150 × 90 × 65 mm, balancing performance and space efficiency. The module’s hardware is built to endure demanding factory environments, ensuring consistent performance amid noise, vibration, and temperature fluctuations. With precision control over automated processes, it assists in reducing downtime and improving production quality.

| Parameter | Value |

|---|---|

| Model | CU313A |

| Brand | KEBA |

| Type | Industrial Control Module |

| Power Supply | 220V AC |

| Frequency | 30 kHz |

| Dimensions | 150 × 90 × 65 mm |

| Application | Automation control for manufacturing and robotics |

The CU313A integrates well with servo amplifiers, drives, and I/O expansion units from various manufacturers, enabling seamless control solutions. Installation requires firm mounting, proper electrical connections, and compliance with safety and grounding standards. Regular maintenance involves firmware updates, functional diagnostics, and inspection for wear or connectivity issues.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626