Description

The IOC4T 200-560-000-1130 functions as a multi-channel input/output control module, positioned at the edge of the automation stack where field devices meet the control network. It accepts a wide range of analog and digital signals from sensors (such as temperature, pressure, and flow transducers) and actuators (including valves, motors, and relays), converting them into a standardized format compatible with PLCs, DCS, or SCADA systems.

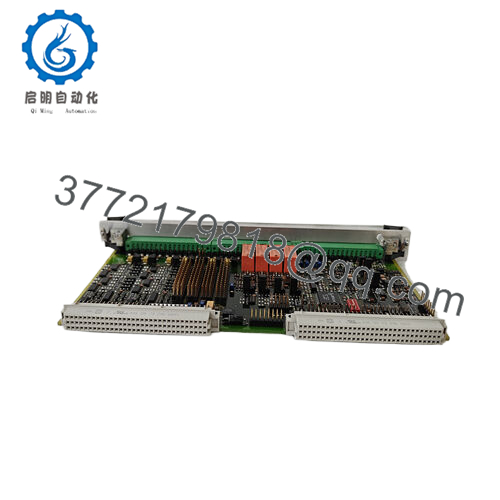

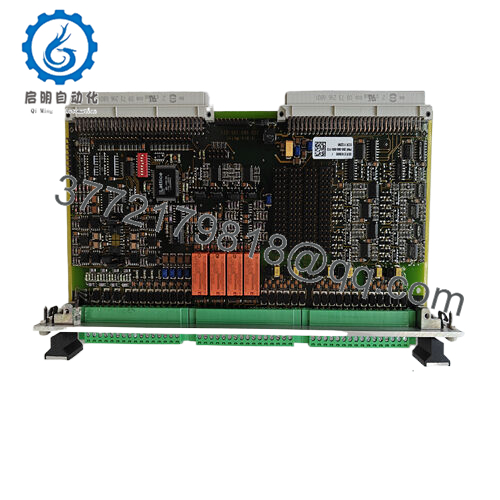

IOC4T 200-560-000-1130

Unlike basic I/O modules with fixed signal types, the IOC4T 200-560-000-1130 offers configurable channels, allowing engineers to assign analog inputs, analog outputs, digital inputs, or digital outputs based on specific application needs. This flexibility eliminates the need for multiple specialized modules, simplifying system architecture. The module connects to the control system via a high-speed industrial bus, ensuring real-time data transfer with minimal latency. It also features built-in signal conditioning—including filtering and isolation—to reduce noise interference common in factory floors or process plants, ensuring signal integrity even in electrically noisy environments.

IOC4T 200-560-000-1130

Technical specifications:

Model Number IOC4T 200-560-000-1130

Brand GE

Type Configurable I/O Control Module

Input Voltage 24V DC (redundant power options)

Operating Temp Range -20°C to 70°C (-4°F to 158°F)

Mounting Style DIN rail (35mm) or panel mount

Dimensions 160mm x 100mm x 60mm (LxWxH)

Weight 350g

Interface/Bus PROFINET, Modbus TCP/IP

Compliance CE, RoHS, UL 1604 (Class I, Div 2)

Supported Signals Analog (0-10V, 4-20mA), Digital (24V DC)

Channel Count 16 configurable channels (8 max analog)

Typical Power Draw 4.5W

contact us:

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

IOC4T 200-560-000-1130

Main features and advantages:

Engineered for industrial durability and operational efficiency, the IOC4T 200-560-000-1130 delivers tangible benefits that enhance system reliability and reduce lifecycle costs. Its wide operating temperature range and rugged construction—including a metal housing and conformal-coated circuit boards—enable reliable operation in harsh environments, from freezing cold warehouses to high-temperature process areas, eliminating the need for expensive climate-controlled enclosures. The configurable channels reduce inventory complexity, as a single module can replace multiple fixed-function I/O cards, lowering procurement and storage costs. For maintenance teams, the IOC4T 200-560-000-1130 simplifies troubleshooting with LED status indicators for each channel, providing instant visual feedback on signal presence or faults. This allows technicians to quickly isolate issues (e.g., a failed sensor or broken wire) without extensive testing, reducing downtime. The module’s signal isolation also protects the control system from voltage spikes or ground loops originating in the field, preventing damage to expensive PLC or DCS components.

IOC4T 200-560-000-1130

Application areas:

The IOC4T 200-560-000-1130 excels in applications requiring flexible I/O management across diverse industries. In chemical processing plants, it monitors and controls batch reactors by accepting analog inputs from pH and level sensors while sending digital outputs to control feed valves, adapting easily to recipe changes that require reconfiguring signal types. In automotive assembly lines, the module handles digital inputs from proximity sensors (detecting part presence) and analog outputs to control robotic gripper pressure, ensuring precise part handling without switching hardware. In water treatment facilities, it integrates with flow meters (4-20mA) and chemical dosing pumps (0-10V), with configurable channels allowing operators to repurpose the module for different treatment stages (e.g., filtration vs. disinfection) as plant needs evolve. Its hazardous location certification (UL 1604) also makes it suitable for oil and gas applications, such as monitoring pressure in storage tanks or controlling valves in non-sparking zones.

Related products:

GE HE693THM666

Triconex 3009

Triconex 3624

Schneider PMC-2/11/04/001/00/03/10/00/10

FIREEYE 95DSS2-1

Tmeic ARND-3110N

smc INR-244-264

GE IC697CPM790

GE IC754VGF15CTD

MacGregor 2141357-804

MacGregor 2141232-802

LAM 839-101612-885

EMC VISATRON VN115/87

Cole Morgan 60WKS-CE240/12PB

TRICONE 3625

TRICONEX 3625

Berger Lahr EXRDM3913/50NEA

TRICONEX 3625

SAACKE HMI10-M REV215

EATON XVS-460-15MP1-1-10

Honeywell HMR2300-D21-485

KONGSBERG RCU502

KONGSBERG RDIOR420

KONGSBERG RSER200-4

KONGSBERG WCC600

GE IS220PDIAH1A

ELAU SM140-30-120-P0-45-M1-B1

GE IS220PDIAH1B

TRICONEX 3625

TRICONEX 3625

Schneider C600/10/1/1/1/00

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONE 3721

TRICONEX 3721

DANIEL DANIEL S600+

schneider XBTGT6340

A-B 1326AB-B720F-21K7-SERIESC

Schneider MICOMP139

PACIFIC SCIENTIFIC BLF2924-10-0-S-017

Rockwell 1794-APBDPV1

Rockwell SST-PB3-SLC

Rusgard LLC GE RS-FS-9001

GE PQMII-C-A

Honeywell IQView8/24

Honeywell IQVIEW4/24

GE F35-W00-VFH-F8L-H6L-M6L-PXX

Yokogawa NFCP100-S05 S3

Woodward 5466-409

TRICONEX 3721

THK TD-020CU-200AC-G15M-5J-N

SIMPLEX 4100-5113

Vibration Monitor AMS3120-A3120/022-000

YOKOGAWA CP451-50S2

HIMA PS1000WR011

YOKOGAWA 3500/22M-01-01-00 288055-01

HONEYWELL FC-SCNT01

Schneider SH30552P11A2000

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626