Description

The IOC-555-D functions as a high-density digital I/O module, positioned between field devices (such as limit switches, solenoids, and proximity sensors) and the central control system (PLCs or DCS). Unlike standard I/O modules with limited channel counts, it packs 32 digital inputs and 32 digital outputs into a space-efficient design, reducing the number of modules needed in control panels and simplifying wiring harnesses. The module connects to the control system via a high-speed industrial Ethernet bus (PROFINET RT), enabling deterministic data transfer with cycle times as low as 1ms—critical for time-sensitive applications like synchronized conveyor systems.

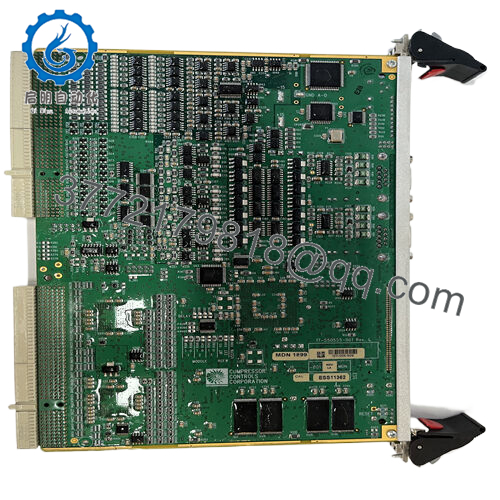

IOC-555-D

What sets the IOC-555-D apart is its built-in signal filtering and surge protection: each channel is isolated to prevent ground loops and electromagnetic interference (EMI), ensuring signal integrity even near large motors or welding equipment. It also features configurable input/output modes (e.g., sinking/sourcing outputs, normally open/closed inputs), allowing seamless integration with diverse field devices without additional adapters.

IOC-555-D

Main features and advantages:

Engineered for industrial ruggedness and operational efficiency, theIOC-555-D delivers tangible benefits that reduce costs and improve system performance. Its high channel density cuts down on panel space requirements by up to 50% compared to standard 16-channel modules, freeing up room for other components and simplifying panel design. The PROFINET RT interface ensures low-latency communication, making it ideal for applications where precise timing is critical—such as coordinating robotic pick-and-place operations with conveyor stops. For maintenance teams, the module’s diagnostic features simplify troubleshooting: each channel has an LED status indicator, and built-in fault logging (via the control system) records events like short circuits or overcurrent conditions, allowing technicians to quickly identify faulty devices or wiring issues. The rugged construction—including a metal housing and conformal coating—ensures reliability in harsh environments, from dusty warehouses to washdown areas (IP20-rated with optional protective cover), reducing replacement frequency and unplanned downtime.

Technical specifications:

Model Number IOC-555-D

Brand GE

Type High-Density Digital I/O Module

Input Voltage 24V DC (with reverse polarity protection)

Operating Temp Range -30°C to 70°C (-22°F to 158°F)

Mounting Style DIN rail (35mm)

Dimensions 120mm x 80mm x 60mm (LxWxH)

Weight 300g

Interface/Bus PROFINET RT (100Mbps)

Compliance CE, RoHS, IEC 61010-1

Channel Configuration 32 digital inputs (24V DC), 32 digital outputs (24V DC, 0.5A per channel)

Output Protection Short-circuit, overcurrent, and overtemperature protection

Typical Power Draw 6W

contact us:

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

Application areas:

The IOC-555-D excels in applications requiring high-density digital control across industries. In automotive assembly plants, it manages signals from hundreds of proximity sensors monitoring part positioning on assembly lines, while controlling solenoid valves for clamping tools—all within tight cycle times to meet production targets. In packaging machinery, the module coordinates digital inputs from film tension sensors with outputs to sealers and cutters, ensuring precise synchronization that minimizes material waste. In logistics and material handling, it integrates with barcode scanners (inputs) and conveyor diverters (outputs), enabling real-time routing of packages based on scanned data. Its wide temperature range makes it suitable for cold-storage facilities, where it controls freezer door actuators and monitors door position sensors without performance degradation. For system integrators, the IOC-555-Dsimplifies scaling: adding more I/O capacity requires only daisy-chaining additional modules via PROFINET, avoiding the need for complex backplane upgrades.

Related products:

Installation and maintenance:

Before installing the IOC-555-D, verify that the control system’s PROFINET firmware supports RT (real-time) communication; older PLCs may require a firmware update to achieve sub-1ms cycle times. Ensure the DIN rail is securely mounted to prevent vibration-induced loosening, which can disrupt connections. Check that the 24V DC power supply can deliver at least 250mA per module (accounting for maximum output current across all channels).

During wiring, use twisted-pair cables for input signals to minimize EMI, and terminate unused channels to prevent noise pickup. Configure input filtering (0.1ms to 10ms) via the manufacturer’s software to match the application—faster filtering for high-speed sensors, slower for noisy environments. For ongoing maintenance, inspect LED indicators monthly to confirm all channels are operating correctly; a steady red light on an output channel indicates a short circuit. Clean the module’s ventilation slots quarterly to prevent dust buildup, which can impair heat dissipation. Every two years, verify output current limits using a clamp meter to ensure protection circuits are functioning.

Other product models:

REXROTH R901254695 VT-HNC100-2-3X/N-I-00/000

GE HE693THM666

Triconex 3009

Triconex 3624

Schneider PMC-2/11/04/001/00/03/10/00/10

FIREEYE 95DSS2-1

Tmeic ARND-3110N

smc INR-244-264

GE IC697CPM790

GE IC754VGF15CTD

MacGregor 2141357-804

MacGregor 2141232-802

LAM 839-101612-885

EMC VISATRON VN115/87

Cole Morgan 60WKS-CE240/12PB

TRICONE 3625

TRICONEX 3625

Berger Lahr EXRDM3913/50NEA

TRICONEX 3625

SAACKE HMI10-M REV215

EATON XVS-460-15MP1-1-10

Honeywell HMR2300-D21-485

KONGSBERG RCU502

KONGSBERG RDIOR420

KONGSBERG RSER200-4

KONGSBERG WCC600

GE IS220PDIAH1A

ELAU SM140-30-120-P0-45-M1-B1

GE IS220PDIAH1B

TRICONEX 3625

TRICONEX 3625

Schneider C600/10/1/1/1/00

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONE 3721

TRICONEX 3721

DANIEL DANIEL S600+

schneider XBTGT6340

A-B 1326AB-B720F-21K7-SERIESC

Schneider MICOMP139

PACIFIC SCIENTIFIC BLF2924-10-0-S-017

Rockwell 1794-APBDPV1

Rockwell SST-PB3-SLC

Rusgard LLC GE RS-FS-9001

GE PQMII-C-A

Honeywell IQView8/24

Honeywell IQVIEW4/24

GE F35-W00-VFH-F8L-H6L-M6L-PXX

Yokogawa NFCP100-S05 S3

Woodward 5466-409

TRICONEX 3721

THK TD-020CU-200AC-G15M-5J-N

SIMPLEX 4100-5113

Vibration Monitor AMS3120-A3120/022-000

YOKOGAWA CP451-50S2

HIMA PS1000WR011

YOKOGAWA 3500/22M-01-01-00 288055-01

HONEYWELL FC-SCNT01

Schneider SH30552P11A2000

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626