Description

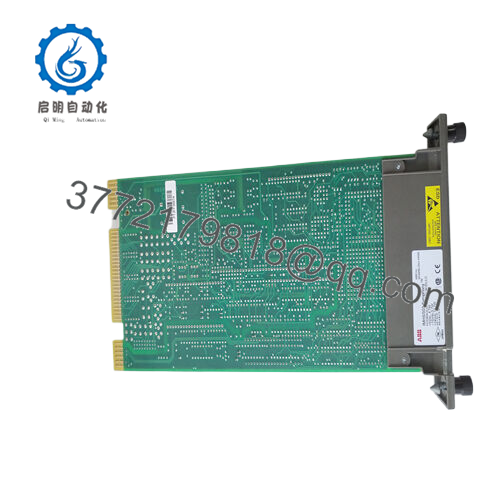

IMHSS03 Product Description:

IMHSS03 is a safety shutdown module designed using solid-state silicon carbide (SiC) technology, aimed at providing deterministic safety control for industrial environments. As a core component of fault-tolerant automation architecture, such as T Ü V certified safety PLC systems, it serves as the ultimate authority in emergency situations, covering normal control signals to execute predefined safety states. Unlike traditional electromechanical relays, IMHSS03 uses solid-state switching technology to eliminate mechanical wear and ensure reliable operation over millions of cycles.

IMHSS03

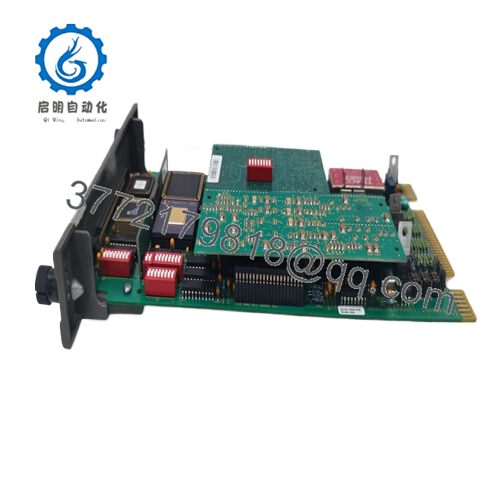

This module is designed for seamless integration with programmable safety controllers such as Allen Bradley GuardLogix or ABB safety PLCs, occupying a critical position in the safety hierarchy: it receives commands from the safety PLC and drives actuators such as emergency stop valves, motor brakes, or ventilation baffles. For engineers, its value lies in reducing hardware complexity – one IMHSS03can replace up to 20 traditional relays in typical safety circuits, reduce panel space by 50%, and simplify troubleshooting through built-in diagnostic LEDs.

IMHSS03

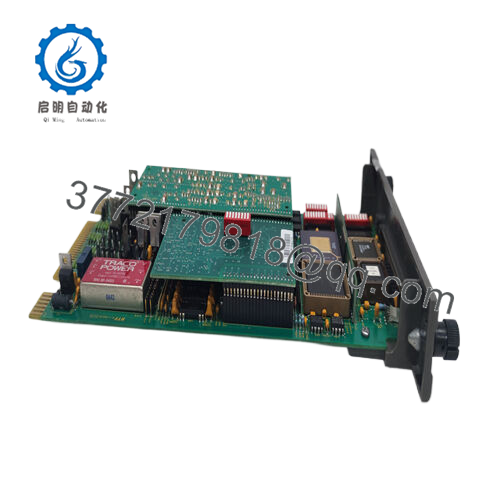

Main features and advantages:

Ultra reliable solid-state design

Based on silicon carbide technology, the switching speed of this module is 10 times faster than traditional silicon-based devices, with a turn off time of less than 10 milliseconds – which is crucial for preventing chain reactions in chemical processes. Its fault prevention design includes dual channel redundancy, with each channel independently verifying safety signals; If a fault is detected in one channel, the other channel will automatically take over to ensure zero single point of failure.

Extreme environmental adaptability

This module can operate reliably within a temperature range of -55 ° C to 125 ° C and is suitable for harsh environments such as blast furnaces, deep-sea subsea systems, and other traditional relays that rapidly degrade. Its sealed casing (IP68) can prevent the intrusion of dust, water immersion (up to 10 meters deep), and corrosive gases (such as hydrogen sulfide H ₂ S). Tests have shown that it can withstand 100 g vibration (IEC 60068-2-6) and 2000 V surge immunity (IEC 61000-4-5), making it very suitable for heavy machinery and earthquake prone areas.

Intelligent security integration

This module has built-in IO Link connection function, which can transmit real-time diagnostic information to the maintenance system. Engineers can monitor key indicators such as contactor health, voltage fluctuations, and thermal performance through a dedicated dashboard to achieve predictive maintenance and replace components before faults occur. Its T Ü V SIL 3 certification (IEC 61508) ensures compliance with the highest safety integrity level, reducing audit complexity in regulated industries.

IMHSS03

IMHSS03

Technical specifications:

Model IMHSS03

Brand ABB

Type Solid State Security Shutdown Module

Power supply 24 VDC (± 20%)

Working temperature -55 ° C to 125 ° C

Installation method DIN rail (35mm)

Size 90 x 60 x 40 millimeters

Weight 0.3 kilograms

Switching voltage 24-250 VDC/48-480 VAC

Switching current 10 A (resistive load)

Safety Integrity Level SIL 3 (T Ü V certified)

Communication interface IO Link 1.1, Modbus RTU

Protection level IP68, NEMA 4X

Certification CE, UL, ATEX, IECEx

Contact Us

Mobile:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

IMHSS03

Application areas:

In industries where safety is crucial, IMHSS03 is the cornerstone of operational resilience. Chemical production plants rely on this advanced industrial safety shutdown system to reduce risks when handling volatile solvents or managing hazardous operations such as high-pressure reactors. This module continuously monitors key parameters such as gas leaks, overpressure, and temperature spikes, and triggers immediate shutdown or bypass operations to prevent catastrophic failures. For example, in pharmaceutical facilities producing active pharmaceutical ingredients (APIs),IMHSS03ensures compliance with ISO 14001 environmental standards by suspending processes that exceed allowable emission thresholds.

In energy intensive industries such as mining and metallurgy, IMHSS03 plays a crucial role in protecting personnel and equipment. At the gold refining site, it is integrated with flame detectors and toxic gas sensors to automatically activate emergency protocols in the event of a fire or ammonia leak, reducing response time from minutes to milliseconds. Its sturdy design also makes it suitable for offshore oil platforms, where salt corrosion and extreme weather conditions require a system with anti failure capabilities that can withstand continuous vibration and humidity.

The production lines in the automotive industry utilize IMHSS03 to mandate the establishment of safety zones around robot units. By connecting with the light curtain and pressure sensing pad, the system ensures that the machinery only operates when personnel are away from hazardous areas, in compliance with OSHA and ANSI B11.19 machine protection standards. This not only prevents work-related accidents, but also reduces production delays caused by safety related shutdowns.

Related products:

IMHSS01- Basic security module for low-risk applications, supporting 4 channels instead of 8.

IMHSS03-R – Redundant version, equipped with dual power inputs, suitable for nuclear grade safety systems.

IMEDS02- Emergency Stop Button Station, pre wired to directly connect with IMHSS03.

IMGAS04- Gas detection module, which transmits real-time H ₂ S/CO data to IMHSS03 to trigger automatic shutdown.

IMTEM05- Temperature sensor array, used to monitor hotspots in motors or pipelines, compatible with IMHSS03 analog input.

IMLOG06- Safety Data Recorder, records IMHSS03 activation events for compliance reporting.

IMPWR07- Uninterruptible Power Supply (UPS) module to ensure the operation of IMHSS03 during short-term power outages.

Installation and maintenance:

Precautions before installation:

Use shielded twisted pair cables for signal wiring to reduce electromagnetic interference (EMI) in high-power environments.

Ensure that the DIN rail is grounded according to IEC 60364 standard to prevent damage from electrostatic discharge (ESD).

For multi module settings, leave a 25mm gap between each unit to facilitate air circulation and thermal management.

Maintenance Guide:

Perform functional safety testing using the manufacturer’s software every quarter to verify that all channels respond within the specified shutdown time (<10 milliseconds).

Check the connectors annually for corrosion or looseness, especially in damp or salt spray environments.

As part of the planned safety lifecycle upgrade, modules should be replaced every 10 years even if no faults are detected – this is consistent with the guidelines of IEC 61508 for SIL 3 systems.

Store the spare module in anti-static packaging at room temperature to extend the lifespan of the components.

Other ABB product models:

ABB PM861AK01 3BSE018157R1

ABB PM633 3BSE008062R1

ABB Al630 3BHT300011R1

ABB 3BHL000986P3003 5SDF1645L0006

ABB 3BHB004744R0010

ABB 3BSE023732R1

ABB PU519 3BSE018681R1

ABB PM877 3BDH000777R1

ABB 83SR51R1210 GJR2396200R1210

ABB AO2000 LS25

ABB 1SDA053999R1

ABB CI854BK01 3BSE069449R1

ABB DI830 3BSE013210R1

ABB PM645B

ABB 3BHE035301R0001 UNS 0121 A-Z,V1

ABB 3BHE035301R1002 UNS 0121A-Z,V1

ABB AO810V2

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101

ABB XVC517AE10 3BHB004744R0010

ABB UFC760BE1042 3BHE004573R1042

ABB UFC760BE141 3BHE004573R0141

ABB NAVIGATOR 600 V20

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626