Description

Real-World Use & Application Scenarios

The ICS T9802 digital input termination assembly is designed for use in safety-critical industrial environments such as nuclear power plants, chemical processing, oil and gas, and large-scale manufacturing. It is specifically built to handle multiple digital input signals with high integrity and fault tolerance, crucial in distributed control systems (DCS) and safety instrumented systems (SIS). The module ensures accurate termination and conditioning of input signals from field devices like sensors and switches, solving common industrial challenges related to noise, signal reflection, and interference. Quickly identifying and stabilizing these inputs helps maintain system safety, operational continuity, and precise control, which are essential in complex and regulated industrial processes.

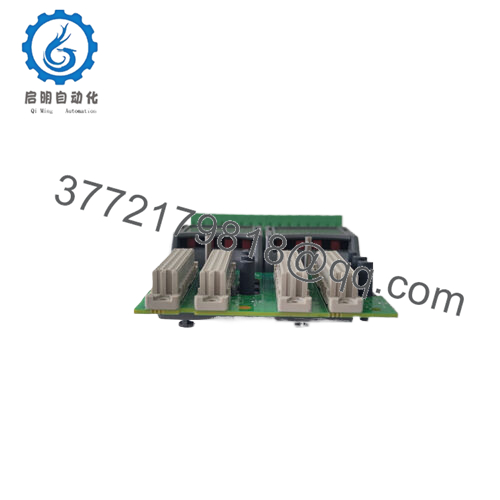

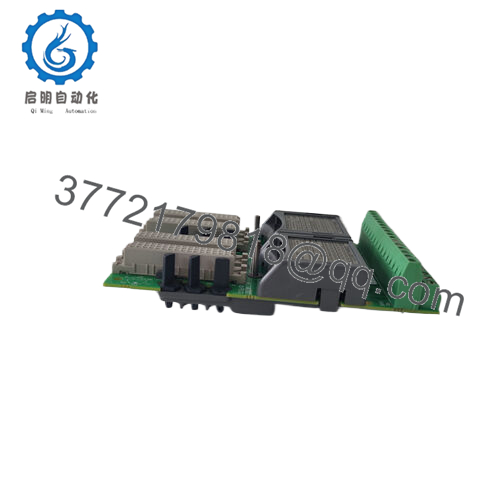

Product Introduction & Positioning

The ICS T9802 is a 16-channel, dual-isolated digital input termination assembly engineered for harsh industrial conditions and safety applications. This module is part of the ICS Triplex AADvance family, certified to Safety Integrity Level 3 (SIL3) under IEC 61508 standards, ensuring it provides the highest level of functional safety. It isolates and conditions digital input signals to deliver clean, stable data to control processors, thereby maintaining system reliability. The dual isolation design enhances noise immunity and signal integrity, preventing cross-channel interference. The ICS T9802 fits within ICS Triplex rack systems, enabling easy system integration, scalability, and retrofit options. Its robustness and certifications make it ideal for engineers tasked with building fail-safe and resilient automation systems.

Key Technical Features & Functional Benefits

The ICS T9802 supports 16 digital input channels with individual dual isolation, which improves system accuracy and protects against common industrial fault conditions such as ground loops and electromagnetic interference. It operates at 24 V DC with a current capacity up to 2 A per channel, accommodating a wide variety of input devices.

T9802

The module is ruggedized to withstand vibration levels up to 5g RMS across 10 to 500 Hz and shocks of 30g with 11 ms half-sine pulses, making it suitable for installation in physically demanding environments. Its mean time between failures (MTBF) exceeds 100 years, emphasizing its reliability for long-term operation in critical systems.

Advanced diagnostics provide real-time monitoring of channel status and faults, enabling rapid troubleshooting and minimizing downtime. The module’s design allows hot-swapping and easy replacement, supporting high system availability and straightforward maintenance.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | ICS T9802 |

| Brand | ICS Triplex / General Electric |

| Product Type | 16-Channel Dual-Isolated Digital Input Termination Assembly |

| Number of Channels | 16 |

| Input Voltage | 24 V DC |

| Input Current per Channel | Up to 2 A |

| Isolation | Dual-channel isolation |

| Operating Temperature | -20°C to +70°C |

| Vibration Resistance | 5g RMS (10 to 500 Hz) |

| Shock Resistance | 30g, 11 ms half-sine |

| MTBF | >100 years |

| Mounting | ICS Triplex system racks |

| Certifications | SIL3 (IEC 61508) |

Related Modules or Compatible Units

ICS T9401 – 8-Channel digital input module providing complementary I/O capacity.

ICS T9402 – 16-channel digital input module with isolated channels for enhanced signal integrity.

ICS T9851 – Digital output module designed for ICS Triplex platforms.

ICS T9451 – Analog input module expanding system measurement capabilities.

ICS T9100 – Processor module for high-reliability safety systems.

ICS T9085 – Auxiliary diagnostic and interface extension module.

Installation Notes & Maintenance Best Practices

Install the ICS T9802 in compliant ICS Triplex rack units ensuring secure connector engagement and correct wiring practices to optimize system reliability. Ground loops and electromagnetic interference should be controlled through proper shielding and grounding to maintain signal integrity.

Routine maintenance involves checking diagnostic indicators for channel health and fault states. Periodic visual inspection and cleaning of connectors are essential to prevent corrosion and connectivity issues. The module supports hot-swapping allowing quick replacement without system interruption, essential for minimizing maintenance downtime in critical applications.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626