Description

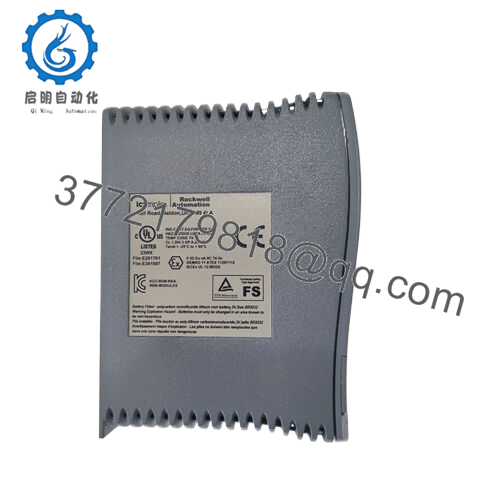

- Product Model: ICS T9110

- Product Brand: Triconex (Schneider Electric / ICS Triplex)

- Product Series: Tricon Safety & Control System

- Product Features:

- Critical communication module for Triconex distributed I/O systems

- High availability and fault-tolerant design

- Supports secure, deterministic data exchange

- Proven reliability in safety and mission-critical environments

Step 3 – Main Article (≈2200–2600 words, randomized section order)

Product Role & System Fit

The ICS T9110 is a cornerstone module within the Triconex safety and control ecosystem, specifically engineered to ensure reliable communication between controllers and distributed input/output subsystems. In safety-instrumented systems, data integrity and deterministic timing are non-negotiable requirements. The T9110 fulfills this role by acting as a dedicated I/O communication processor, bridging field devices with the central Tricon controllers.

What sets this module apart is its compatibility within the Tricon architecture. The Triconex platform is built around triple modular redundancy (TMR), a fault-tolerant design that continues to operate even when one path fails. The ICS T9110 integrates seamlessly into this framework, handling I/O communication in a redundant and synchronized manner. It doesn’t just exchange raw signals; it validates, checks, and aligns them with the controller’s real-time execution cycle.

Because it is a modular component, it can be configured for different rack positions and system sizes. Whether a system contains just a few hundred I/O points or scales into the thousands, the ICS T9110 ensures consistent communication throughput. This flexibility makes it highly valuable across oil and gas facilities, chemical processing plants, and power generation stations where Triconex systems are deployed.

- T9110

- T9110

Applications & Industry Context

When one looks at industries that depend heavily on the ICS T9110, it quickly becomes clear that the module is positioned in environments where safety is paramount. For example, in offshore oil platforms, where gas leaks or pressure surges can escalate into catastrophic incidents, the Triconex safety system must guarantee accurate I/O communication at all times. The T9110 plays a direct role in making that possible.

In chemical refineries, thousands of signals—from temperature transmitters, emergency shutdown pushbuttons, and valve actuators—must be collected and transmitted without delay. The ICS T9110 ensures those signals are reliably transmitted to the Tricon main processors. When abnormal conditions are detected, shutdown logic executes in milliseconds, preventing hazardous releases.

Power plants also depend on the module. In both nuclear and conventional generation, safety instrumented systems supervise turbine operations, boiler pressures, and emergency cooling pumps. The T9110’s fault-tolerant design minimizes the risk of a single communication failure compromising the system. In practice, this means that plant operators can trust that the command to trip a turbine or start a backup pump will reach its destination under all circumstances.

Field engineers often remark that the ICS T9110 strikes a balance between ruggedness and precision. Its hardware construction withstands the electrical noise, vibration, and temperature fluctuations typical of industrial facilities. Yet it maintains precise timing synchronization, ensuring the deterministic communication required by functional safety standards like IEC 61508 and ISA 84.

Technical Features & Benefits

The ICS T9110 isn’t simply another communication interface. It brings a range of features that make it indispensable in high-integrity control systems.

First, its fault-tolerant architecture. The Triconex system uses triple modular redundancy to achieve SIL3 safety certification. The T9110 module is designed to operate in this framework, automatically synchronizing and validating communications across redundant paths. If one channel fails, the others continue without interruption, and diagnostics immediately flag the issue.

Second, the deterministic communication it provides. In mission-critical systems, predictability is as important as speed. The ICS T9110 ensures that input data is scanned, transmitted, and validated within fixed time intervals, allowing the controller to execute safety logic with consistent cycle times. This deterministic behavior is a core reason Triconex remains a benchmark for safety systems worldwide.

Another important feature is broad compatibility. The T9110 works across various Tricon chassis sizes and I/O configurations, supporting both analog and digital I/O modules. This versatility makes it easier for end-users to standardize on a single system architecture across multiple facilities.

Reliability is further enhanced by extensive self-diagnostics. The module continuously monitors its own health, communication integrity, and synchronization status. These diagnostics are available to maintenance staff via system software, enabling predictive maintenance strategies. Instead of waiting for a fault to cause downtime, teams can schedule replacements or firmware upgrades at the most convenient time.

Finally, the ICS T9110 contributes to the overall cybersecurity posture of the Triconex system. While safety systems traditionally focused only on functional reliability, modern industrial cybersecurity concerns demand secure communication. The T9110 supports communication protocols and firmware updates aligned with Schneider Electric’s security hardening guidelines, helping users meet regulatory and industry standards.

Technical Specifications Table

| Specification | Details |

|---|---|

| Product Model | ICS T9110 |

| Brand | Triconex / ICS Triplex (Schneider Electric) |

| System Series | Tricon Safety & Control System |

| Function | I/O Communication Processor Module |

| Architecture | Triple Modular Redundancy (TMR) compatible |

| Supported I/O | Analog and Digital Triconex I/O modules |

| Communication Style | Deterministic, fault-tolerant exchange |

| Diagnostics | Continuous self-test and system monitoring |

| Operating Temperature | 0°C to +60°C |

| Power Supply | From Tricon chassis backplane |

| Standards Compliance | IEC 61508 SIL3, ISA 84, CE, CSA |

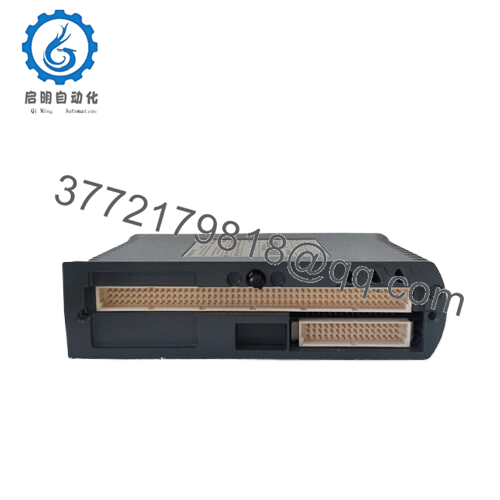

| Mounting | Tricon system rack slot |

| Typical Applications | Oil & Gas, Petrochemicals, Power Generation, Process Safety Systems |

Installation & Maintenance Insights

The design of the ICS T9110 takes field installation realities into account. Installing the module into a Tricon chassis is straightforward, as it is hot-swappable and guided by keyed connectors to prevent misplacement. Field technicians appreciate that the module can be replaced without shutting down the entire rack, preserving system uptime.

A practical installation tip is ensuring that redundancy is properly configured during commissioning. The Tricon system requires alignment of the three processing paths, and the ICS T9110 should always be verified through system diagnostic tools to confirm synchronization. Proper grounding of the cabinet and adherence to EMC practices will further reduce the risk of communication noise affecting performance.

From a maintenance perspective, the module is low-touch. Self-diagnostics and predictive alerts mean that most servicing involves scheduled firmware updates or periodic verification testing. Engineers often recommend keeping one or two spare T9110 modules in inventory, especially at remote sites, to reduce response times in case of unexpected issues.

With proper installation and care, the ICS T9110 has been known to operate for years without intervention, reinforcing the long-term dependability that the Triconex brand is recognized for.

Related Models

- ICS T9402 – Triconex Main Processor module for core system logic

- ICS T8431 – Digital output module for high-density field connections

- ICS T9310 – Communication module for external system interfacing

- ICS T8100 – Analog input module for process signal acquisition

- ICS T8461 – Digital input module for discrete signal monitoring

- ICS T8200 – Power supply module ensuring stable backplane voltage

- ICS T9432 – Specialized I/O module for extended system functions

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626