Description

| Specification | Description |

|---|---|

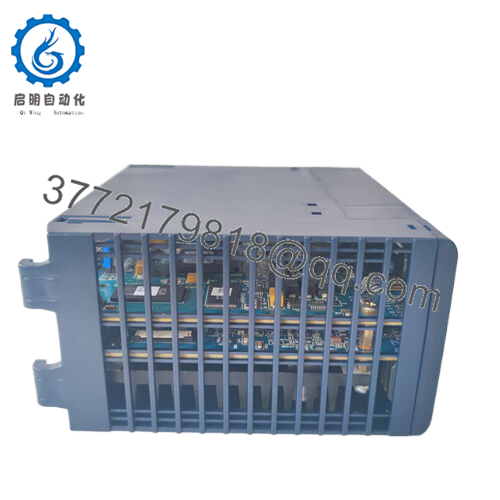

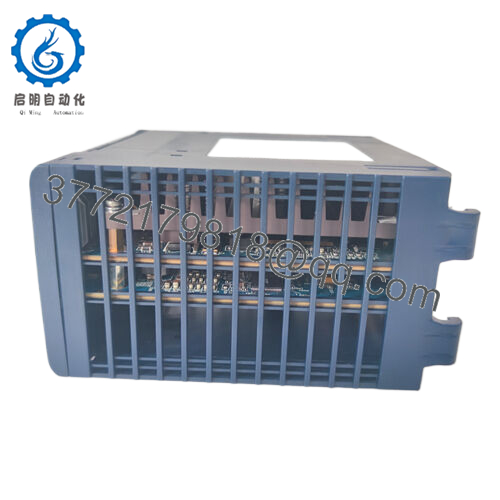

| Model Number | IC695CPE305-AE |

| Product Type | Programmable Automation Controller CPU |

| Series | PACSystems RX3i |

| Processor | High-performance CPU for real-time control |

| Memory | Nonvolatile storage for logic and configuration |

| Communication | Integrated Ethernet interfaces |

| Backplane | RX3i Universal Backplane |

| Power Requirements | Provided by RX3i rack power supply |

| Programming Software | Proficy Machine Edition |

| Environmental Rating | Industrial operating range |

| Firmware Upgrade | Supported via Proficy tools |

| Redundancy | Compatible with RX3i redundancy systems |

Product Model: IC695CPE305-AE

Product Brand: GE

Product Series: PACSystems RX3i

Product Features:

• High-speed logic execution with integrated Ethernet

• Robust diagnostics and reliable nonvolatile memory

• Ideal for large or distributed RX3i architectures

• Industrial-grade durability for 24/7 operation

- IC695CPE305-AE

- IC695CPE305-AE

Applications & Industry Context

While the technical specifications tell one story, real on-site use tells another. The IC695CPE305-AE has become a widely deployed choice across industries where reliability must be treated as a non-negotiable requirement. One of the most common application areas is manufacturing—especially heavy industries like automotive component production, plastics molding, and engineered-metal fabrication. These plants rely on PLCs to coordinate dozens of synchronized steps, and any delay or logic error could halt an entire line.

The module also fits neatly into the energy sector. Power generation and distribution facilities often use PACSystems RX3i controllers to manage switchgear, monitor load conditions, and automate critical safety logic. The IC695CPE305-AE offers enough communication flexibility to integrate SCADA data, field I/O, and redundant systems without compromising timing accuracy.

Water and wastewater treatment plants represent another valuable example. Treatment cycles involve pumps, valves, clarifiers, chemical dosing systems, and continuous sampling instruments. These operations must run day and night, often in aging facilities where equipment is spread across multiple buildings or remote stations. The IC695CPE305-AE performs well here because it can maintain robust communication across diverse I/O modules, and it doesn’t break a sweat managing long scan cycles.

Food and beverage processors also appreciate the controller. Many production lines require hygienic, tightly controlled processes to ensure food safety and regulatory compliance. Oven control systems, blending machines, packaging lines, and CIP (clean-in-place) loops benefit from the predictable logic execution that the IC695CPE305-AE delivers.

I’ve personally seen it used in material-handling facilities supporting large warehouses. Conveyors, sorting arms, barcode readers, shuttle systems—all of these depend on responsive, coordinated control. In facilities processing tens of thousands of parcels per hour, a PLC hesitation of even one second could create downstream chaos. The IC695CPE305-AE keeps pace with the rapid movement of goods without introducing unwanted latency.

In short, the controller thrives wherever real-time coordination, distributed I/O, and high uptime requirements intersect.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626