Description

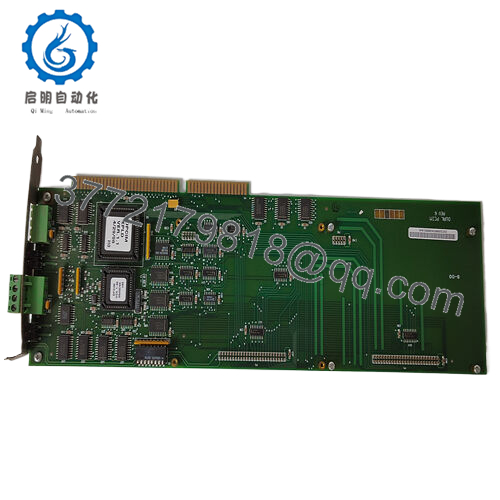

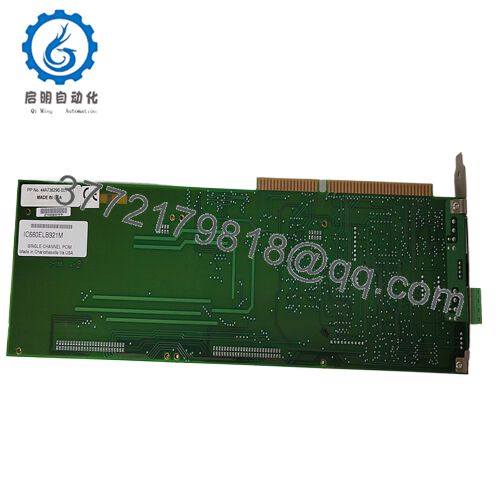

Product Model: IC660BBA104

Product Brand: GE / GE Fanuc

Product Series: Genius I/O Series

Product Features:

- Stable analog signal processing for distributed automation

- Durable field-mountable enclosure designed for harsh environments

- Seamless integration within GE Genius bus networks

- Proven reliability in continuous industrial operations

- IC660BBA104

- IC660BBA104

Technical Specifications Table

| Specification | Description |

|---|---|

| Model Number | IC660BBA104 |

| Brand | GE / GE Fanuc |

| Series | Genius I/O Series |

| Module Type | Analog Block |

| Input Type | Configurable analog channels |

| Power Requirements | Genius I/O standard field supply |

| Isolation | Channel-to-bus isolation |

| Communication | Genius bus network |

| Mounting Method | Field-mounted, rugged enclosure |

| Operating Temperature | Industrial-rated temperature range |

| Compatibility | GE Genius controllers and bus interface units |

| Application | Process control, distributed I/O environments |

Technical Features & Benefits

The design of the IC660BBA104 reflects years of GE experience building distributed I/O systems capable of running continuously without fuss. One of the biggest advantages of this module is its ability to maintain high signal integrity. Anyone who has spent time troubleshooting analog loops in noisy areas knows how crucial clean input conversion is. The Genius line gives attention to shielding, grounding paths, and stable A/D processing. This translates into fewer recalibrations and more trustworthy input data feeding upstream PLCs or controllers.

Another benefit is how easily the block fits into a Genius I/O network. The Genius bus was designed with flexibility in mind, allowing modules of different types to share information without extensive rewiring. The IC660BBA104 snaps into this architecture naturally, speaking the same communication language as other Genius modules, which simplifies troubleshooting and network expansion. System integrators often favor this series because they can scale it incrementally—adding blocks as needed without reconstructing entire control cabinets.

The rugged enclosure plays a larger role than many realize. Industrial floors often expose electronics to dust, moisture, unusual temperature cycles, and mechanical stress. By placing I/O blocks directly in the field, GE needed to ensure long-term reliability. The enclosure of the IC660BBA104 is built to shield internal components while allowing convenient access to terminals and indicators. The result is a module that handles harsh conditions surprisingly well. I’ve heard technicians mention that these blocks are among the last pieces of equipment to fail in plants where heat and vibration slowly wear down everything else.

From a performance standpoint, the module’s configurable channels give it a versatility that suits plants with changing process requirements. Instead of locking into a single fixed behavior, the block can adapt to a variety of analog input conditions. Whether measuring temperature, pressure, flow, or position-feedback devices, the IC660BBA104 provides dependable readings that operators and control systems rely on.

Its isolation features are another unsung advantage. Isolation barriers protect the network from unexpected voltage differences or wiring mishaps in the field. In plants where grounding conditions vary, this protection can prevent cascading failures. For integrated systems with sensitive control components upstream, isolation is one of the simplest ways to protect the system against expensive damage.

Taken together, these features make the IC660BBA104 a well-rounded and field-proven choice for distributed analog acquisition in modern and legacy automation environments alike.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626