Description

In the unforgiving pulse of industrial automation, where process control systems hinge on uninterrupted power to orchestrate valves, sensors, and logic solvers without a whisper of falter, the fragility of single-source feeds can unravel even the most fortified architectures—sparking voltage sags that corrupt I/O signals, trigger spurious shutdowns, or cascade into full blackouts during transient loads. Envision a continuous polymer extrusion line, where a momentary AC glitch halts extruder drives and cooling fans, yielding miles of scrap and hours of restart rituals, or a desalination plant where power dips amid peak draw from reverse osmosis pumps compromise membrane integrity, inflating energy costs and compliance risks under ISO 50001. These episodes are not rarities; they’re the undercurrents in utilities and manufacturing, where scaling redundant I/O for expanded telemetry strains non-failover supplies, demanding high reliability to align with IEC 61508 SIL 2/3 without spawning thermal hotspots or harmonic distortions that erode MTBF. Engineers, navigating volatile grids or harmonic-prone VFD farms, often confront protracted swaps or overspec’d UPS layers that bloat footprints and budgets, morphing power provisioning into a protracted vulnerability rather than a seamless enabler.

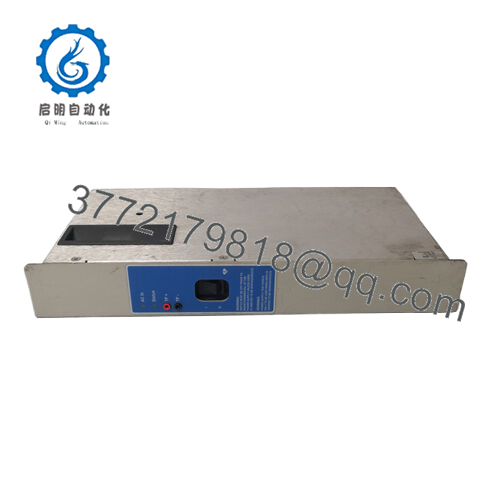

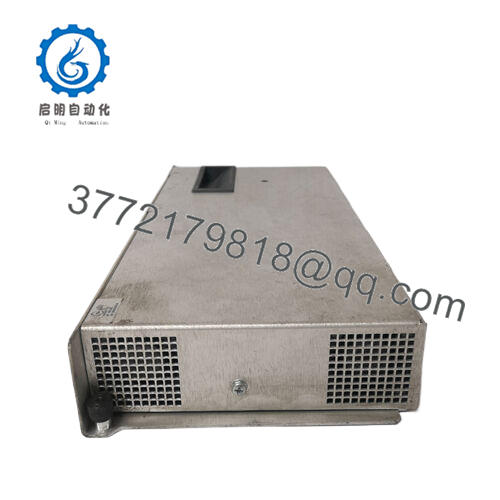

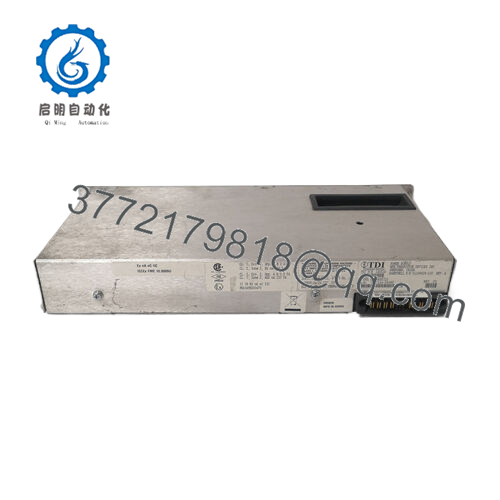

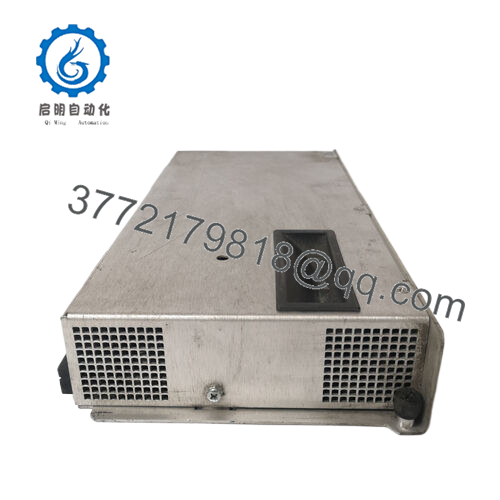

This is the redundancy rift the Honeywell SPS5710 51199929-100 mends as a dual-output power supply module for C300 controllers, forged by Transistor Devices Inc. (TDI) to deliver fault-tolerant 24 VDC rails in compact, hazardous-rated enclosures. In sprawling setups like offshore ESD skids or batch reactor farms, it asserts indispensability during capacity swells, where proliferating field modules outpace legacy PSUs; sans such a unit, crews grapple with brownout-induced logic resets that skew process variables or invite ESD false trips. The Honeywell SPS5710 51199929-100 redresses by converting universal AC inputs to twin 20A/24 VDC outputs, engineered for hot-swap paralleling without bridging diodes, while its Class I Div 2/Zone 2 hardening shrugs off corrosive vapors or dust incursions. This eclipses basic rectification—it’s a conformal-coated dynamo with overcurrent clamps and thermal derating that sustains peak loads, logging faults for preemptive forensics to preserve I/O signal constancy.

For those charting power architectures, the Honeywell SPS5710 51199929-100 elucidates anchors: it trims failover transients to under 10 ms via output sharing, tunable through Experion PKS for load balancing, and its wide AC tolerance streamlines global deploys sans transformers. In control-centric domains where outages eclipse thousands per minute, this module’s diagnostic relays forewarn degradations, recasting supply susceptibilities into resilient reservoirs. Whether energizing a C300 rack in flare gas recovery or buffering turbine governors, the Honeywell SPS5710 51199929-100 endows your scaffold with the modular integration that underpins process control, interweaving steadfast conversion with unobtrusive scalability to endure amid electrical exigencies.

Tethered to the C300 controller’s chassis core, the Honeywell SPS5710 51199929-100 presides as the vital vigor source, DIN-railing into the power assembly where it siphons 100-240 VAC across 47-63 Hz to forge dual 24-26 VDC rails at 20A each, sans backup for AC-loss holdup but primed for external battery tandem. It interfaces via the baseplate’s distribution bus, energizing IOM slots—flanking digital scanners or analog conditioners—with isolated feeds that decouple loads, averting ripple propagation to sensitive ASICs. In the I/O continuum, it anchors upstream from field terminations, downstream of AC mains, where conditioned DC cascades to controllers and FIMs, fostering redundancy by paralleling a mate for N+1 resilience without derating.

Its emplacement resonates with field pragmatism: no bespoke firmware, just plug-compatible terminals for 10A inrush handling, while embedded thermistors cue the host via Modbus for ambient alerts, preempting overheat scrams. For a reactor charge sequence, the Honeywell SPS5710 51199929-100 balances draw from pump starters and valve coils, clamping surges below 30 V to shield PLC transients; overvoltage crowbars (28 V trip) sever faults autonomously. This fulcrum amplifies the stack’s tenacity—dovetail with FTA boards for SIL 3 zoning, or scale via daisy-chained racks for 100+ I/O sprawl—while epoxy barriers defy 95% RH in Div 2 atmospheres. The Honeywell SPS5710 51199929-100 thereby coalesces as a judicious fount, where current flows with guarded grace, and metrics muster endurance rather than exhaustion.

- SPS5710 51199929-100

| Specification | Details |

|---|---|

| Model Number | SPS5710 51199929-100 |

| Brand | Honeywell (TDI) |

| Type | Dual-Output Power Supply Module |

| Input Voltage | 100-240 VAC |

| Operating Temp Range | -20°C to +60°C |

| Mounting Style | DIN-rail / Chassis |

| Dimensions | 200 x 100 x 50 mm (approx.) |

| Weight | 1.2 kg |

| Interface/Bus | C300 Power Bus |

| Compliance | IEC 61508 SIL 2/3, Class I Div 2 Zone 2, CE, RoHS |

| Supported Protocols | Modbus (via host) |

| Typical Power Draw | 480 W (output capacity) |

Incorporating the Honeywell SPS5710 51199929-100 erects a reliability bastion where dual rails distribute loads sans hot spots, letting C300 cycles sustain 99.999% availability through grid flickers—your loops evade the voltage valleys that once veiled resets, all while harmonic filters (<5% THD) tame VFD backwash in shared feeders. In thermal-stressed bays, its derating curves (80% at 60°C) preserve output sag below 2%, engineered to outlast 10-year cycles without capacitor swaps.

The curation ethos veers to augury, as fault relays and voltage monitors surface ripple anomalies via host queries, isolating a degrading rectifier in streams before blackout brink—contracting downtime from outage hunts to heuristic hints and lightening engineering for capacity forecasts over fixes. Conceived for the fray of baseload barrages, it vows perennial potency through vibration-quelled mounts that brave 2 g spectra, inflating MTBF beyond 300,000 hours while pruning spares to fuse arrays. For burgeoning enclosures, the Honeywell SPS5710 51199929-100‘s chassis perch hastens rail extensions, eluding rewire rigors, liberating leeway for edge computing on power profiles.

Amplify the ambit, and its bus telemetry pipelines metrics to asset arenas, interlacing supply logs with I/O yields to sketch failure fabrics preemptively. Stewards operate with bolstered belief, as threshold transgressions surface as lucid beacons, abridging rally chains in surge shades. Electing the Honeywell SPS5710 51199929-100 instills a fount that foretells frailties, amalgamating tenacious transformation with tactical tenacity to elevate your industrial automation from episodic to emblematic.

In ethylene crackers, the Honeywell SPS5710 51199929-100 vitalizes compressor skids amid hydrocarbon heats and quench chills, where feed interruptions imperil yields—its dual outputs cement critical system uptime, energizing solenoids in process control environments to avert surge without yield forfeits.

Substation auxiliaries embed it for breaker coil banks, defying arc flashes and humidity hauls; under these harsh conditions, the Honeywell SPS5710 51199929-100‘s SIL 3 scaffolding confers high reliability, paralleling rails for faultless trips in fast data cycles across grid nodes.

Within dairy pasteurizers, it powers valve manifolds from CIP pumps, with RoHS rapport suiting sanitary refits—output bounty enables consolidated feeds, diminishing clutter in regulated process control environments. These tableaux exalt the Honeywell SPS5710 51199929-100‘s mettle for curators channeling current conundrums.

51199929-200 – Enhanced variant with integrated 24V backup for AC-loss bridging in remote C300 setups

SPS5700 51199928-100 – Single-output counterpart for non-redundant power in compact enclosures

CC-TPS01 – Termination power supply companion for field I/O extensions alongside SPS5710

MC-PAOY22 51202372-200 – Analog output module downstream for load testing SPS5710 rails

CC-SDIP02 – Digital input processor pairing for event monitoring on SPS5710 feeds

MC-TSIM12 51204146-200 – Simulation module for bench-validating SPS5710 redundancy

SPS5720 51200001-100 – High-capacity 40A model for dense C300 racks augmenting SPS5710

CC-MAIN01 – Controller hub integrating multiple SPS5710 supplies in Series C clusters

When marshaling the Honeywell SPS5710 51199929-100 into your C300 chassis, attune AC inlet to grid phase—post-50 Hz ensures inrush harmony, per Honeywell’s provisioning playbook, so a clamp meter prelude unmasks imbalances. Appraise enclosure efflux; in >60% burdened bays, decree 25 CFM exhausts to moor heatsinks shy of 60°C, and oscilloscope your VAC span for <5% sag—confederating a line reactor forestalls harmonic hiccups. Interrogate output terminals for dielectric strength over 2kV, as latent contaminants can corrode isolation from day one.

In incumbency, trimestral host polls for ripple ripples past 100 mV consort with front LEDs for balanced rail glows. Semiannually, enact load proofs via external dummies—ramp to 80% draw to affirm sharing below 5 ms—and cinch bus clamps to 1.2 Nm, heedful of creep in vibratory vaults. For vapor-veiled perches, annual conformal canvasses via endoscope discern delams forthwith, conjoined with metric marshals for anomaly arcs. These observances entwine into power patrols, cherishing the Honeywell SPS5710 51199929-100‘s perpetuity sans lavish leeches.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626