Description

The Honeywell R7247C1001 is a flame amplifier module widely deployed in industrial burner management systems for gas, oil, and coal-fired applications. It is used in safety-critical environments such as power plants, refineries, and large-scale heating installations where reliable flame detection and rapid flame failure response are essential to prevent unsafe operating conditions. The amplifier processes signals from ultraviolet (UV) flame sensors and supports rapid flame failure responses typically within 2 to 4 seconds, which is vital for ensuring burner safety and regulatory compliance.

Industries rely on the R7247C1001 for its dynamic self-checking capabilities that continuously monitor flame presence and amplifier performance, reducing false alarms and unplanned shutdowns. Its compatibility with multiple primary safety controls and flame sensors makes it a flexible and essential component for safeguarding combustion processes under harsh conditions.

Product Introduction and Positioning

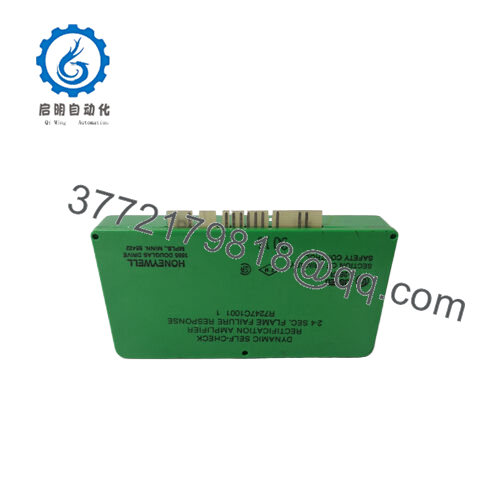

The Honeywell R7247C1001 is a solid-state plug-in flame amplifier module designed specifically to work with Honeywell’s BC7000 series and other flame safeguard controllers like R4140 and R4075 models. It interprets input signals from flame detectors and signals the control system regarding flame status, enabling safe startup, operation, and shutdown sequences.

- R7247C1001

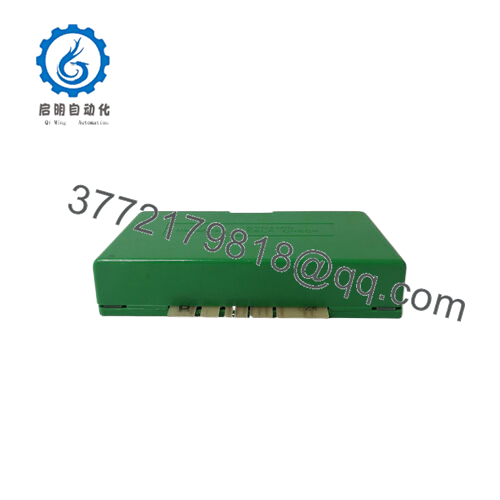

Positioned as a critical safety component in burner management systems, the R7247C1001 incorporates advanced rectification amplifier technology and dynamic self-check features that ensure continuous monitoring and reliability. Its plug-in design supports easy replacement and integration in existing Honeywell flame safeguard architectures.

Key Technical Features and Functional Benefits

The R7247C1001 flame amplifier responds to UV flame sensor inputs with a fast flame failure response time of 2 to 4 seconds, balancing sensitivity with safety. Its dynamic self-checking function continuously verifies amplifier health and flame presence, significantly reducing the risk of undetected faults or false flame loss indications.

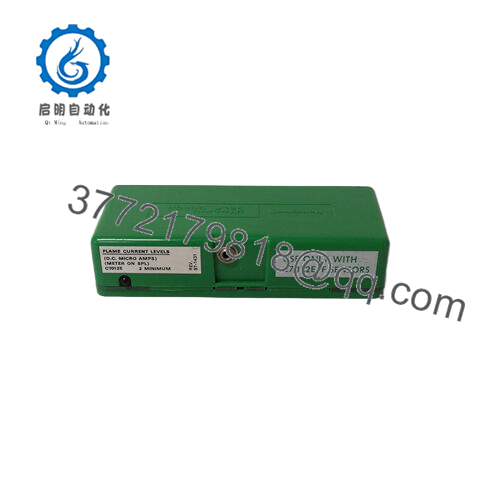

Designed with durability in mind, the module features a robust green-colored housing and conforms to multiple safety and performance certifications including Underwriters Laboratories (UL) and Factory Mutual (FM). It works seamlessly with compatible flame detectors such as the C7012E/F UV sensors, providing consistent, reliable flame supervision.

The amplifier supports safe start checks, flame signal amplification, and fault diagnostics essential for regulatory compliance in burner safety systems. Its plug-in format facilitates straightforward maintenance, helping reduce downtime and service costs.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | R7247C1001 |

| Brand | Honeywell |

| Product Type | Flame Amplifier Module |

| Flame Failure Response Time | 2 to 4 seconds |

| Compatible Flame Sensors | C7012E, C7012F Ultraviolet |

| Self-Checking | Dynamic Self-Check |

| Primary Safety Controls | BC7000, R4140, R4075C/D/E, R4138C/D, FSP5075 |

| Housing Color | Green |

| Certifications | UL Listed, FM Approved |

| Operating Temperature Range | -40 to +60 °C |

| Dimensions (Approx.) | 124 mm (H) x 216 mm (W) x 102 mm (D) |

| Weight | ~240 grams |

Related Modules or Compatible Units

R4140 – Flame safeguard controller compatible with R7247 flame amplifier modules.

R4075C/D/E – Series of flame supervisory controls used alongside the R7247C1001.

FSP5075A1/A3 – Flame amplifier modules supported by similar flame safeguard systems.

C7012E/F – Ultraviolet flame sensors designed for use with the R7247C1001.

BC7000 Series – Primary safety control systems integrated with Honeywell flame amplifier modules.

Installation Notes and Maintenance Best Practices

Install the R7247C1001 in positions recommended by Honeywell within flame safeguard cabinets, ensuring firm plug-in connections and proper electrical grounding. The flame sensors connected through the amplifier should be regularly inspected and cleaned to maintain sensitivity and reliability.

Routine testing and diagnostics using control system tools are critical to ensure the amplifier’s dynamic self-check functions operate correctly. Periodic replacement schedules based on operational hours or manufacturer recommendations can help avoid unexpected failures in safety-critical applications.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626