Description

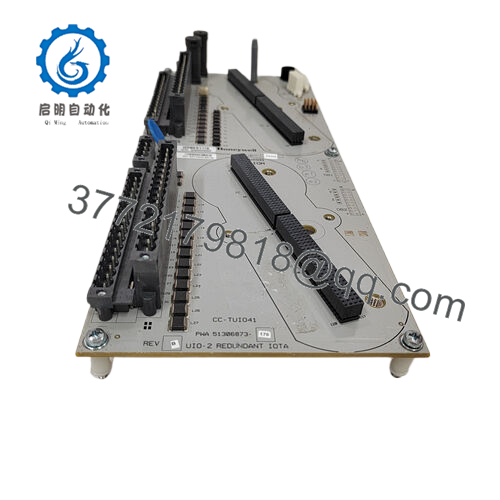

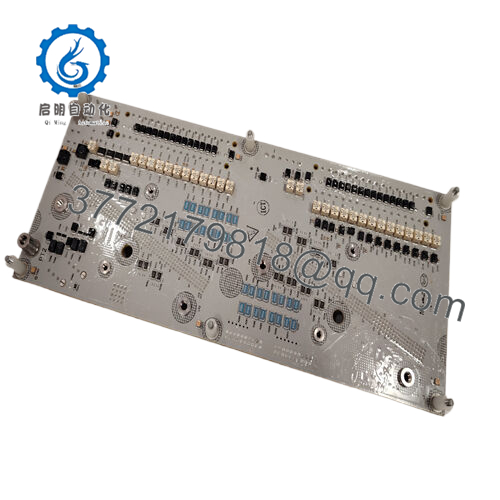

Honeywell CC-TUI041 is an analog input module designed specifically for industrial applications. It is an important component of Honeywell’s comprehensive industrial control product suite, designed to seamlessly integrate into distributed control systems (DCS), programmable logic controller (PLC) based devices, and other industrial automation architectures.

CC-TUI041

This module is a key connecting link between analog sensing field devices (such as sensors) and digital processing components of control systems (such as controllers and data acquisition units). Its main function is to convert analog input signals received from various sensors into digital signals that can be easily processed and analyzed by the control system. In Honeywell’s product ecosystem, CC-TUI041 is typically used in conjunction with other input/output (I/O) modules, controllers, and software platforms to create a complete integrated control and monitoring solution. Engineers and system integrators value the reliability, accuracy, and ease of integration of CC-TUI041, making it the preferred choice for various industrial projects ranging from new installations to modernization of existing systems.

CC-TUI041

Main features and advantages:

Multiple input channels

CC-TUI041 is usually equipped with multiple analog input channels, and based on the model name, it is often four channels. This multi-channel configuration enables it to interface with multiple sensors simultaneously. In industrial processes that require monitoring multiple parameters, such as temperature, pressure, and flow at different points in pipelines, the 4-channel capacity of CC-TUI041 allows it to handle all of these inputs without the need for multiple modules, simplifying overall system design and reducing costs.

Wide input signal range

This module is designed to accept a wide range of analog input signals. It is typically capable of processing voltage signals ranging from 0-10V DC, 0-5V DC, or ± 10V DC, as well as current signals ranging from 4-20mA. This broad signal range compatibility makes it suitable for a wide variety of sensors on the market. For example, it can interface with temperature sensors that output 0-5V DC signals proportional to the measured temperature, as well as pressure sensors that provide 4-20mA current signals based on pressure values.

High precision signal conversion

CC-TUI041 provides high-precision analog-to-digital conversion. It can accurately convert analog input signals into high-resolution digital values. This high-precision conversion is crucial in applications where even small changes in the measured parameters can have a significant impact. For example, in chemical manufacturing processes, precise measurement of reactant flow rate and reaction temperature is crucial to ensure product quality and safety. CC-TUI041 can provide accurate digital representations of these analog signals, enabling the control system to make precise adjustments and maintain optimal process conditions.

Built in signal conditioning

To improve the quality of input signals and enhance the overall performance of the module, CC-TUI041 is equipped with built-in signal conditioning function. It can filter out electrical noise and interference that may exist in analog input signals. In industrial environments, electromagnetic interference generated by motors, transformers, and other electrical equipment is common, and this signal conditioning function is very valuable. It ensures that the control system receives clean and accurate signals from sensors, reducing the possibility of misreading and erroneous operations.

Isolation function enhances safety and reliability

This module typically has an isolation function between the input channel and the rest of the control system, usually electrical isolation. This isolation can prevent electrical faults such as short circuits and voltage surges. If there is an electrical problem with the sensor or the circuit connecting the sensor toCC-TUI041, isolation can prevent damage to the control system and other components. It also helps to improve the reliability of the module by reducing the impact of electrical noise and interference on the input signal.

Compliant with industry standards

CC-TUI041 complies with relevant industry standards, such as the International Electrotechnical Commission (IEC) standards. Compliance with these standards ensures that the module can be easily integrated into existing industrial control systems that comply with these specifications. It also ensures that the quality, safety, and interoperability of the product reach a certain level. For example, in manufacturing plants that already have control systems based on IEC compatible components, CC-TUI041 can be added or replaced without significant compatibility issues, simplifying the process of system expansion or upgrade.

Technical specifications:

Model CC-TUI041

Brand Honeywell

Type Analog Input Module

Input channel 4

Input signal type voltage (0-10V DC, 0-5V DC, ± 10V DC) and current (4-20mA)

Analog digital resolution with high resolution (e.g. 16 bits, depending on the model, can achieve precise signal conversion)

High precision, usually within ± 0.1% of the full-scale reading

Signal conditioning with built-in filtering to reduce noise and interference

Electrical isolation between isolated input channels and control systems

The power supply is usually 24V DC, and some models have a wider operating voltage range of 12V to 36V DC

Low power consumption, usually below 3W

Working temperature range -20 ° C to+60 ° C

Humidity range 5% to 95% (non condensing)

Compact size design

Weight approximately 0.3 kilograms

Contact Us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

Application areas:

In modern intelligent buildings, CC-TUI041 plays a crucial role in building automation systems. It can be used to connect and manage various environmental sensors, such as indoor air quality (IAQ) monitoring sensors. By continuously receiving analog input signals from IAQ sensors that measure pollutants such as volatile organic compounds (VOCs), particulate matter (PM), and carbon dioxide (CO ₂), CC-TUI041 provides real-time data for building management systems. These data are then used to control ventilation systems, air purifiers, and other HVAC components, optimize indoor air quality, and provide a comfortable and healthy environment for building users.

Both renewable energy sources such as fossil fuels, wind or solar power, and nuclear power plants rely on CC-TUI041. For example, in a wind farm, this module can interface with sensors that measure wind speed, direction, and turbine blade angle. By accurately processing the analog input signals of these sensors, it helps the wind turbine control system adjust the pitch angle of the blades and the orientation of the turbine to achieve optimal power generation. In thermal power plants, it can be used to monitor and measure the analog signals of sensors for steam temperature, pressure, and flow, ensuring the efficient and safe operation of power generation equipment.

Related products:

Honeywell CC-TDOB01: This is a digital output module. In industrial control systems, CC-TUI041 may receive analog input signals from sensors and then be processed by the control system. According to the processing result, the control system may send a digital output signal to CC-TDOB01. CC-TDOB01 can use these signals to drive actuators such as relays, motors, or solenoid valves. For example, if CC-TUI041 detects that the process temperature is too high through a temperature sensor, the control system can use CC-TDOB01 to start the cooling fan or valve to adjust the temperature.

Honeywell C300 Controller: CC-TUI041 can be integrated with Honeywell C300 Controller. The C300 controller is responsible for processing the overall control logic based on input data from various sources, including analog input data from CC-TUI041. It analyzes the digital values received from CC-TUI041, makes control decisions, and may send commands to other components of the control system. In process control applications, the C300 controller may adjust the set values of the process based on the analog input signal of CC-TUI041 to ensure that the process operates within the required parameter range.

Sensor: CC-TUI041 is designed to interface with multiple sensors. These sensors include temperature sensors such as thermocouples, resistance temperature detectors (RTDs), or thermistors; Pressure sensors, such as resistive or capacitive pressure sensors; Flow sensors, such as electromagnetic or ultrasonic flow sensors; And many other sensors. This module is compatible with sensors that output analog signals within its specified input signal range, and can achieve seamless integration in different industrial monitoring and control applications.

Honeywell FTE cables: These cables are used to establish high-speed and reliable communication links between CC-TUI041 and other components of the control system. They ensure that digital data converted from analog input signals can be accurately and timely transmitted to control systems, such as C300 controllers. In large industrial networks, FTE cables can handle the data traffic generated by CC-TUI041, achieving efficient communication within the control system.

Installation and maintenance:

Consider factors before installation

Power verification: Before installing CC-TUI041, it is necessary to verify whether the available power supply meets the requirements of the module. Check the voltage and current ratings to ensure they are within the specified range. If the power supply is unstable, consider using a power regulator or redundant power system. For example, in industrial areas with frequent power fluctuations, a power regulator can be installed to provide a stable 24V DC power supply for CC-TUI041.

Cable routing and termination: Carefully plan cable routing. Due to the multiple input channels of CC-TUI041, there will be many cables connected to it. Ensure that the cable routing method can minimize electromagnetic interference to the greatest extent possible. Use shielded cables to better prevent external electrical noise. When terminating cables, strictly follow the manufacturer’s guidelines to ensure proper electrical connections. Loose or incorrect cable termination may result in signal loss, incorrect readings, or electrical faults.

Environmental assessment: Evaluate the installation environment. Although CC-TUI041 is designed to operate in industrial environments, extreme conditions such as excessive dust, high humidity, or strong vibrations may still affect its performance. If the installation location is in a particularly challenging environment, additional protective enclosures or measures can be considered to mitigate the impact of environmental factors. For example, in dusty factories, modules are installed in sealed enclosures with appropriate ventilation to prevent dust from accumulating on the modules and affecting their electrical contacts.

Maintenance Guide

Regular visual inspection: Conduct regular visual inspections on CC-TUI041. Check for any signs of physical damage, such as cracked casing, loose connectors, or signs of overheating. Check the status indicator lights on the module (if any) to ensure they are functioning properly. Visual inspection helps to detect any potential issues early and prevent more serious situations from occurring. For example, if the connector is found to be loose, it can be tightened immediately to avoid connection failure.

Input signal calibration: Regularly calibrate the input signal of the module. Use Honeywell’s recommended calibration tools and procedures to ensure that the module can accurately convert analog input signals into digital values. Calibration helps maintain the accuracy of modules over a long period of time, especially in applications where precise measurement is crucial. If the calibration is found to be inaccurate, the module settings can be adjusted according to the manufacturer’s instructions.

Firmware Update: Stay up-to-date with the latest firmware released by Honeywell. These updates typically include error fixes, performance improvements, and enhanced compatibility with other control system components. When updating firmware, it is essential to strictly follow the manufacturer’s instructions to avoid any interference with the control system. In some cases, firmware updates may be necessary to address specific issues discovered during module operation, such as improving noise suppression capabilities or enhancing communication capabilities.

Spare parts management: Reserve spare parts for CC-TUI041, especially when it is used for critical applications. This includes spare modules, replacement cables, and connectors. Reserve spare parts can significantly reduce downtime in the event of module failure. Regularly inspect the condition of spare parts to ensure they are in a usable state. For example, regularly testing backup modules to ensure their proper functionality, so that they can be installed immediately when needed.

HONEYWELL related products:

HONEYWELL 2104B2071

HONEYWELL 10012/1/2

HONEYWELL 05701-A-0550

Honeywell 1569905-6131140220

HONEYWELL 05701-A-0351

Honeywell SPS5710 51199929-100

Honeywell QPP-002

Honeywell WEB-600E

HONEYWELL 05701-A-0302

HONELYWELL 900C75-0560

HONEYWELL MC-PDOY22

Honeywell PCNT02

Honeywell TK-PRS021 51404305-375

Honeywell TK-PRR021 51309288-275

Honeywell TK-IOLI01 51403427-175

Honeywell СС-PWRR01

Honeywell FC-PUIO01

Honeywell CC-TUI041

Honeywell TC-IAH161

Honeywell FC-SAO-0220M

Honeywell CC-SCMB02

Honeywell FC-FANWR-24R

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626