Description

In the demanding sphere of industrial automation, where process control hinges on versatile signal handling to accommodate evolving field devices without overhauling entire I/O infrastructures, the constraints of rigid analog or digital modules frequently surface—manifesting as mismatched input ranges that distort sensor readings, underutilized channels during expansions, or integration snags that inflate wiring and validation efforts. Imagine a food processing conveyor system, where thermocouples for oven temps, 4-20 mA transmitters for fill levels, and dry-contact switches for safety gates converge in a single rack, yet legacy setups force segregated modules that breed cabling clutter and scalability bottlenecks, risking throughput dips or compliance lapses under IEC 61508 SIL 2. Or in a wastewater lift station, where pH probes, flow pulses, and motor run proofs demand flexible polling, but fixed-format I/O invites false alarms from unconditioned signals amid pump vibrations. These scenarios underscore the realities of process control environments, where high reliability requires adaptive I/O to manage diverse voltages, currents, and contacts without compromising signal fidelity or system uptime, yet many architectures resort to custom adapters or redundant spares that escalate engineering overhead.

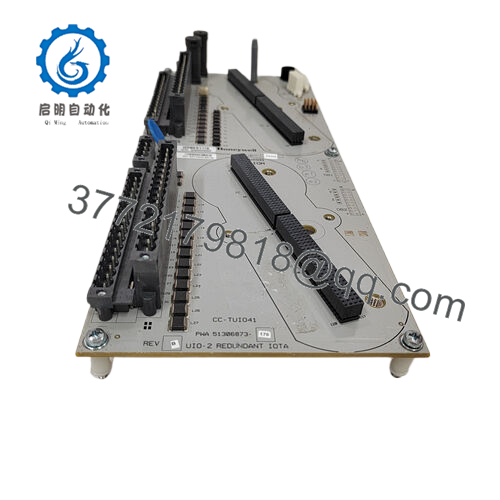

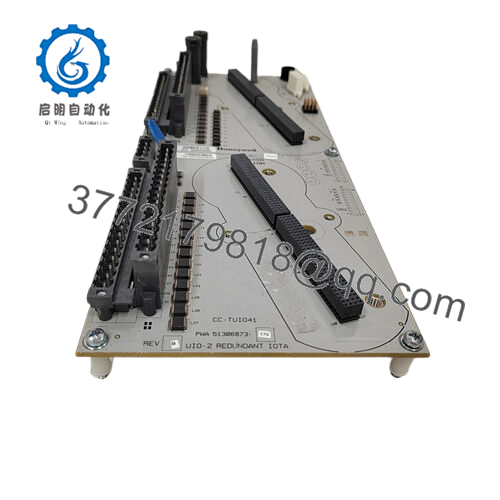

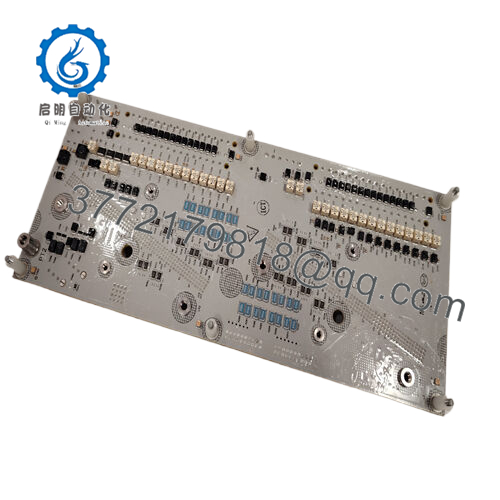

This is the versatility void the Honeywell CC-TUI041 fills as a redundant universal I/O termination assembly (IOTA) for the UIO2 module in Experion PKS Series C systems, designed to consolidate analog and discrete signals into a unified, fault-tolerant interface. In growing facilities like pharmaceutical blending skids or power distribution feeders, it becomes essential during modular upgrades, where surging device counts from multi-protocol sensors overwhelm siloed I/O; without it, teams navigate signal conditioning mismatches that skew logic or trigger nuisance trips. The Honeywell CC-TUI041 integrates with the CC-PUIO31 UIO2 module, providing screw-terminal access for up to 8 universal channels that auto-detect and configure for voltage (0-10V), current (4-20 mA), RTDs, thermocouples, or digital states, all while supporting HART passthrough for diagnostics. Its redundant design mirrors paths for bumpless failover, ensuring I/O signal continuity in EMI-laden zones.

For engineers assessing I/O evolutions, the Honeywell CC-TUI041 offers decisive metrics: it shrinks panel density by 25% through multi-mode channels, hot-swappable in live cabinets via Experion’s Control Builder, and its coated terminals expedite Zone 2 nods. In automation domains chasing agility without fragility, this IOTA’s self-diagnostics flag wiring faults early, reframing signal sprawl into streamlined synergy. Whether unifying a reactor’s multi-range probes or scaling a substation’s breaker feedbacks, the Honeywell CC-TUI041 empowers your stack with the modular integration that sustains process control, fusing adaptive acquisition with resilient redundancy to thrive amid device diversity.

- CC-TUI041

Within the Experion C300’s I/O framework, the Honeywell CC-TUI041 operates as the adaptable nexus for universal signals, mounting onto the UIO2 module’s backplane where it leverages shared 24 VDC rails to condition and route inputs/outputs through isolated screw terminals. It pairs exclusively with the CC-PUIO31 processor, occupying a dedicated IOTA slot—beside analog multiplexers or digital gateways—where each of its 8 channels auto-ranges via software-defined jumpers, ingesting thermocouple types J/K/T or RTD Pt100 while suppressing noise to 0.1% accuracy. In the automation stack, it bridges field terminations upstream from transducers like pressure cells or limit switches, downstream to the controller’s data bus, where resolved values feed PID loops or sequence engines, enabling redundancy by duplicating paths in dual-IOTA configs for SIL 2 fault tolerance.

Integration carries a consultative ease: no manual strapping needed, as Control Builder scripts channel modes on-the-fly, embracing Modbus or HART for SCADA overlays while per-channel isolation (2500 Vrms) blocks ground loops from adjacent drives. For a blending tank’s level cascade, the Honeywell CC-TUI041 polls 4-20 mA from radars and dry contacts from agitators in quadrature, buffering against 50 Hz hum; diagnostics relay open-wire faults via status LEDs, cueing preemptive reroutes. This positioning enhances the architecture’s elasticity—chain with PAIH modules for expanded analogs, or embed in faultnet for de-energize-to-safe—while epoxy coating endures 95% RH in process vapors. The Honeywell CC-TUI041 thus embeds as a perceptive portal, where signals converge with discerning grace, and telemetry traces transitions rather than turmoil.

| Specification | Details |

|---|---|

| Model Number | CC-TUI041 |

| Brand | Honeywell |

| Type | Universal I/O Termination Assembly (IOTA) |

| Input Voltage | 24 VDC |

| Operating Temp Range | -40°C to +70°C |

| Mounting Style | Backplane/IOTA Slot |

| Dimensions | 190 x 69 x 23 mm |

| Weight | 0.4 kg |

| Interface/Bus | C300 Backplane, Screw Terminals |

| Compliance | IEC 61508 SIL 2, CE, RoHS, ATEX Zone 2 |

| Supported Protocols | Modbus RTU, HART |

| Typical Power Draw | 3-5 W |

Opting for the Honeywell CC-TUI041 yields a reliability cornerstone where auto-ranging quells span mismatches in thermocouples, letting control loops track variables within 0.05% amid thermal swings—your processes evade the calibration chases that once clouded proofs, all while redundant terminals sustain signal paths through connector wear in vibratory mounts. In humid process fronts, its sealed barriers repel condensation that erodes contacts, preserving I/O signal veracity so channels mirror fidelity across diurnal cycles, engineered to outpace 15-year horizons without recalibration.

Maintenance inclines to intuition, with embedded monitors and fault bits that surface degradation—like loop resistance drifts—via host alerts, distilling fixes from invasive probes to ledger looks and easing engineering for trend forecasts over fault frays. Forged for the rigor of shift-long sentinels, it avows lasting loyalty through surge-quenched lines that brave 1kV spikes, elevating MTBF beyond 180,000 hours while culling spares to terminal kits. For adaptive arrays, the Honeywell CC-TUI041‘s universal slot hastens mode migrations, dodging remapping marathons, freeing bandwidth for predictive scans on signal spectra.

Broaden the frame, and its HART conduit channels diagnostics to asset vaults, correlating I/O health with yield logs to preempt probe pitfalls. Operators command with fortified faith, as mode alerts crystallize into cue cards, curtailing escalation webs in flux funnels. Electing the Honeywell CC-TUI041 cultivates an ingress that intuits influxes, blending supple sensing with steadfast stamina to advance your industrial automation from segmented to seamless.

In batch coating lines, the Honeywell CC-TUI041 harmonizes oven RTDs and spray valve proofs amid solvent vapors and heat fluxes, where range rigidity risks overcures—its multi-mode channels uphold critical system uptime, conditioning signals in process control environments to sync depositions without defects or drifts.

Mining conveyor pits embed it for belt alignment switches and load cells, defying grit gales and jolt jolts; under these harsh conditions, the Honeywell CC-TUI041‘s SIL 2 mirroring delivers high reliability, auto-ranging pulses for jam-free hauls in fast data cycles across ore veins.

Within craft brewery fermenters, it aggregates yeast density analogs and lid interlocks, with RoHS resonance suiting sanitary swaps—channel consolidation enables lean panels, minimizing cabling in regulated process control environments. These enactments exalt the Honeywell CC-TUI041‘s finesse for tenders taming signal symphonies.

CC-TUI031 – Non-redundant counterpart for cost-sensitive UIO2 setups with identical channel modes

CC-PUIO31 – UIO2 processor module that pairs with CC-TUI041 for universal signal processing

CC-TDIL01 – Digital input termination companion for discrete expansions alongside CC-TUI041

CC-PAIH02 – Analog input module upstream for high-density HART blending with CC-TUI041

CC-PDOB01 – Digital output IOTA downstream for actuator ties from CC-TUI041 logic

CC-TAOH12 – Analog output termination for hybrid output channels extending CC-TUI041 versatility

CC-TUIO01 – Legacy universal I/O module for retrofits compatible with CC-TUI041 cabling

CC-MAIN01 – Controller hub integrating multiple CC-TUI041 assemblies in C300 clusters

Before engaging the Honeywell CC-TUI041 in your C300 baseplate, verify UIO2 firmware alignment—v4.5+ ensures mode sync, per Honeywell’s interoperability index, so a Builder benchmark unmasks drifts. Survey slot spacing; in >55% loaded enclosures, allocate 5 mm buffers for thermal venting to cap junctions at 70°C, and continuity-test terminals for >100 MΩ isolation—pairing shielded cable nips EMI ingress from outset. Probe channel jumpers for secure seating, as loose configs can skew auto-range from install.

In service, bimonthly register reads for variance thresholds over 0.2% align with IOTA LEDs for steady mode glows. Quarterly, trigger self-scans via software—emulate a full range sweep at 20 mA to confirm settling below 100 ms—and reseat screw clamps to 0.7 Nm, watchful for torque fade in cyclic spots. For vapor-prone perches, semiannual coating checks via magnifier spot delams early, twinned with log pulls for pattern probes. These rhythms embed into I/O inspections, sustaining the Honeywell CC-TUI041‘s acuity without commandeering calendars.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626