Description

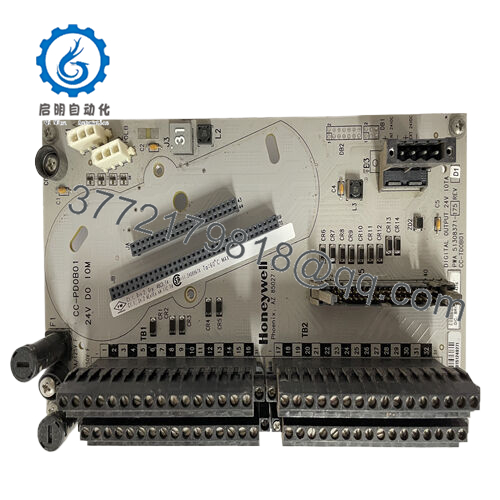

HONEYWELL CC-TDOB01 is a high-performance digital output module designed specifically for industrial automation applications. It is an important component of Honeywell’s extensive industrial control product portfolio, seamlessly integrated into distributed control systems (DCS) and programmable logic controller (PLC) based systems. This module is a critical bridge between the digital decision-making components of control systems (such as PLCs or controllers) and the physical world of actuators.

TDOB01

Its main function is to convert the digital signals received from these control components into switch outputs. These outputs can be used to drive various actuators, including relays, motors, solenoid valves, and indicator lights. In Honeywell’s product ecosystem,CC-TDOB01 is typically deployed alongside other input/output (I/O) modules, controllers, and software platforms to create comprehensive integrated control solutions. Engineers and system integrators value the reliability, flexibility, and ease of integration of CC-TDOB01, making it the preferred choice for new industrial automation projects and existing system upgrades.

TDOB01

Main features and advantages:

High density output channel

CC-TDOB01 typically offers high-density configurations, with some models offering 4, 8, or even up to 32 digital output channels. This high throughput is a game changing factor for industrial applications with limited space, such as in compact control panels or in installations where minimizing module count is crucial to reduce costs. For example, in multi zone climate control systems for large commercial buildings, the 32 channel CC-TDOB01 can be used to independently control heating, ventilation, and air conditioning (HVAC) units in each zone, reducing the need for multiple small capacity modules and simplifying overall system design.

Multiple output types

This module provides multiple output types, with transistor (NPN) output being a common choice. Transistor output is renowned for its fast switching speed, high reliability, and ability to handle relatively high currents. In applications that require fast response time, such as high-speed packaging machinery where actuators need to be activated and deactivated within milliseconds, the transistor output of CC-TDOB01 is an ideal choice. In addition, some versions of the module may also support other output types, such as relay based outputs. Relay output is suitable for applications that require isolation between the control system and the load, as well as applications that drive high voltage or high current loads, such as switching high-power lamps in industrial lighting control systems.

Accurate signal conversion

CC-TDOB01 performs excellently in accurately converting digital signals into appropriate switch outputs. It can accurately convert the binary 0 and 1 of the control system into the on/off state required for operating the actuator. This high-precision signal conversion is crucial for applications where even slight deviations in the output signal may result in low operational efficiency or product defects. For example, in semiconductor manufacturing facilities,CC-TDOB01is used to control the movement of wafer handling equipment. Accurate digital signal conversion ensures that wafers move with sub micron precision, which is crucial for the production of high-performance microchips.

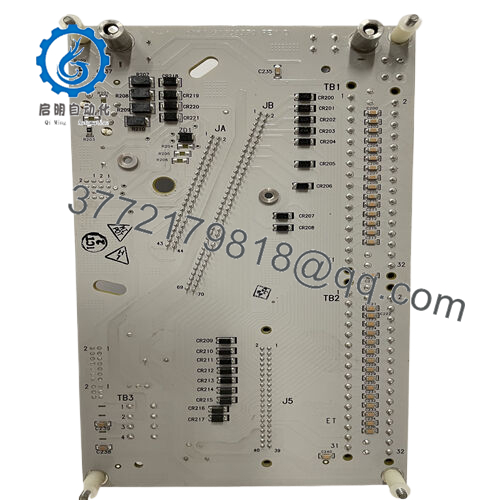

Built in protection mechanism

To improve the reliability and service life of modules and connected devices, CC-TDOB01is equipped with multiple built-in protection functions. It usually includes short-circuit protection, which can protect the module and load in the event of an unexpected short circuit in the output wiring. Overload protection is another key function that prevents the module from being damaged when connected to actuators that draw excessive current. In industrial environments, electrical faults may occur due to power surges, mechanical failures of actuators, or improper wiring, and these protective mechanisms are extremely valuable. For example, in a food processing plant where motors and pumps continue to operate, the protection function of CC-TDOB01 ensures that any electrical abnormalities will not damage the module or interrupt the production process.

Wide range of working conditions

CC-TDOB01 is designed to withstand the harsh conditions of industrial environments and has a wide operating temperature range, typically from -20 ° C to+60 ° C, although some data shows that its operating temperature range is wider, from -40 ° C to+85 ° C. This makes it suitable for various environments, from refrigeration facilities to high-temperature industrial furnaces. It can also operate within a relative humidity range of 5% to 95% (non condensing), suitable for humid environments such as near water treatment plants or in tropical regions. The ability of this module to work under these different environmental conditions ensures its applicability across various industries and geographical locations worldwide.

Compatible with industry standards

CC-TDOB01 complies with industry standards such as IEC 61131-2. Compliance with these standards ensures that the module can be easily integrated into existing industrial control systems that comply with these specifications. It also ensures a certain level of quality, safety, and interoperability. For example, in manufacturing plants that already have control systems based on IEC 61131-2 compatible components, CC-TDOB01 can be added or replaced without significant compatibility issues, thereby reducing the complexity and cost of system upgrades or expansions.

TDOB01

Technical specifications:

Model CC-TDOB01

Brand HONEYWELL

Type digital output module

Output type transistor (NPN)

Rated output voltage 24 VDC

Maximum output current of 0.5 A per channel

Number of channels 4, 8, or 32

Working temperature range -20 ° C to+60 ° C

Humidity range 5% to 95% (non condensing)

Isolation between input and output channels with electrical isolation (enhanced anti-interference capability)

Protection function: Short circuit protection, overload protection

Power consumption less than 5W

Relay rated value 5 A @ 250VAC/3A @ 24V DC

Communication interface RS-485

Load capacity up to 250VAC/30VDC

Compact size design in control panel

Weight approximately 0.55 kg

contact us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

Application areas:

Taking busy automobile manufacturing factories as an example, precision and efficiency are the cornerstones of production. CC-TDOB01 plays a core role in controlling the mechanical arms that assemble numerous automotive components. It receives digital signals from the central control system of the factory (processed by a programmable logic controller (PLC) or dedicated controller). Subsequently,CC-TDOB01converts these signals into switch outputs, which activate the solenoid valves that control the hydraulic or pneumatic system of the robotic arm. This seamless transition enables the robotic arm to perform complex actions with millisecond level accuracy, such as grabbing and placing precision components, ensuring smooth operation of the assembly line.

In large-scale chemical processing facilities,CC-TDOB01 plays a crucial role in regulating the flow of various chemicals. It controls a vast network of valves, including small solenoid valves and large electric valves. For example, in the distillation unit, the module can receive digital instructions based on real-time process data such as temperature, pressure, and chemical composition. Then, it converts these digital signals into necessary switch signals to open or close valves, precisely controlling the flow of raw materials and the separation of different chemical components. This not only ensures the efficiency of chemical reactions, but also prevents potential hazards by strictly controlling the process.

Whether it is coal-fired, gas-fired, or renewable energy power plants, they are highly dependent onCC-TDOB01. Taking wind farms as an example, this module is used to control the pitch and yaw mechanisms of wind turbines. The digital signal from the turbine control system (monitoring wind speed, direction, and power output) is sent to CC-TDOB01. Then, the module outputs appropriate switch signals to drive the motor that adjusts the turbine blade pitch for optimal energy capture, or to steer the entire turbine towards the windward direction. This precise control helps to maximize power generation while protecting the turbine from damage caused by excessive wind loads.

Related products:

HONEYWELL CC – TDIL01

This is a digital input module. CC-TDOB01 is responsible for sending digital output signals to actuators, while CC-TDIL01 receives digital input signals from sensors and switches. In industrial control circuits, CC-TDIL01 can detect the status of sensors, such as limit switches indicating the position of moving parts. Then, the input signal can be processed by the control system, which may use CC-TDOB01 to send output signals to actuators (such as motors) to adjust the position of moving parts.

HONEYWELL C300 Controller

CC-TDOB01 can be seamlessly integrated with HONEYWELL C300 controller. The C300 controller is responsible for processing the overall control logic based on input data from various sources, including digital input modules such as CC-TDIL01. Then, it sends digital signals to CC-TDOB01, which converts these signals into switch outputs to drive the actuator. In process control applications, the C300 controller may analyze temperature data from sensors (connected through digital input modules) and use CC-TDOB01 to control heaters or cooling fans to maintain the desired temperature.

HONEYWELL FTE cable

These cables are used to establish high-speed and reliable communication links between CC-TDOB01 and other components of the control system. They ensure accurate and timely transmission of digital output signals. In large industrial networks, FTE cables can handle the data traffic generated by CC-TDOB01, enabling efficient communication between modules and other devices such as controllers and other I/O modules.

actuator

CC-TDOB01 is designed to drive various actuators. These include relays, which can be used to switch high voltage or high current circuits; Electric motors, such as DC motors in conveying systems or AC motors in industrial pumps; Electromagnetic valves, commonly used in fluid control systems; And indicator lights, used to provide visual status information. The output signal of this module is customized according to the specific requirements of these actuators to ensure their normal operation.

Installation and maintenance:

Precautions before installation

Power verification: Before installing CC-TDOB01, it is necessary to verify whether the available power supply meets the requirements of the module. Check the voltage and current ratings to ensure they are within the specified range. If the power supply is unstable, consider using a power regulator or redundant power system. For example, in industrial areas with frequent power fluctuations, a power regulator can be installed to provide a stable 24 VDC power supply for CC-TDOB01.

Cable routing and termination: Carefully plan cable routing. Due to the multiple output channels of CC-TDOB01, there will be many cables connected to it. Ensure that the cable routing method can minimize electromagnetic interference to the greatest extent possible. Use shielded cables to better prevent external electrical noise. When terminating cables, strictly follow the manufacturer’s guidelines to ensure proper electrical connections. Loose or incorrect cable termination may result in signal loss, short circuit, or incorrect output signals.

Environmental assessment: Evaluate the installation environment. Although CC-TDOB01 is designed to operate in harsh industrial environments, extreme conditions such as excessive dust, high humidity, or strong vibrations may still affect its performance. If the installation location is in a particularly challenging environment, consider using additional protective enclosures or taking measures to mitigate the impact of environmental factors. For example, in factories with high levels of dust, modules are installed in sealed enclosures with appropriate ventilation to prevent dust from accumulating on the modules and affecting their electrical contacts.

Maintenance Guide

Regular visual inspection: Conduct regular visual inspections on CC-TDOB01. Look for any signs of physical damage, such as cracked casing, loose connectors, or signs of overheating. Check the status indicator lights on the module (if any) to ensure they are functioning properly. Visual inspection helps to detect any potential issues early and prevent more serious problems from occurring. For example, if the connector is found to be loose, it can be tightened immediately to avoid connection failure.

Output signal testing: Regularly test the output signal of the module. Use a multimeter or signal tester to verify if the switch output is working properly. Send known digital input signals to the module and check if the corresponding output signals meet expectations. This test helps identify any issues in signal conversion or output circuits. If an incorrect signal is detected in an output channel, further investigation is needed to determine the cause, which may be a transistor malfunction, wiring issue, or internal circuit problem of the module.

Firmware Update: Stay up-to-date with the latest firmware released by Honeywell. These updates typically include error fixes, performance improvements, and enhanced compatibility with other control system components. When updating firmware, strictly follow the manufacturer’s instructions to avoid any interruption to the control system. In some cases, firmware updates may be necessary to address specific issues discovered during module operation, such as improving resistance to electrical interference or enhancing communication capabilities.

Spare parts management: Reserve spare parts forCC-TDOB01, especially when used in critical applications. This includes spare modules, replacement cables, and connectors. Having spare parts can significantly reduce downtime in the event of module failure. Regularly check the status of spare parts to ensure they are in normal working condition. For example, regularly testing backup modules to ensure their proper functionality and installing them immediately when needed.

HONEYWELL related products:

HONEYWELL 2104B2071

HONEYWELL 10012/1/2

HONEYWELL 05701-A-0550

Honeywell 1569905-6131140220

HONEYWELL 05701-A-0351

Honeywell SPS5710 51199929-100

Honeywell QPP-002

Honeywell WEB-600E

HONEYWELL 05701-A-0302

HONELYWELL 900C75-0560

HONEYWELL MC-PDOY22

Honeywell PCNT02

Honeywell TK-PRS021 51404305-375

Honeywell TK-PRR021 51309288-275

Honeywell TK-IOLI01 51403427-175

Honeywell СС-PWRR01

Honeywell FC-PUIO01

Honeywell CC-TUI041

Honeywell TC-IAH161

Honeywell FC-SAO-0220M

Honeywell CC-SCMB02

Honeywell FC-FANWR-24R

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626