Description

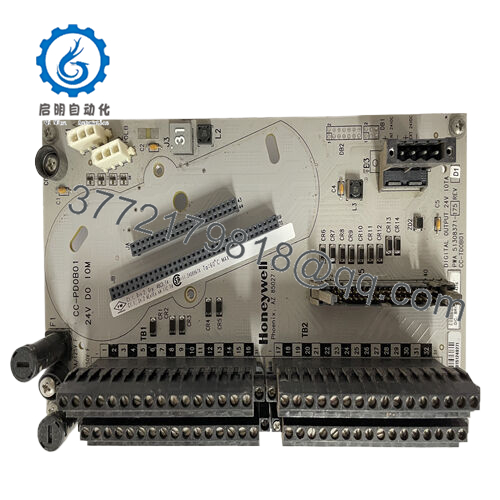

Product Model: Honeywell CC-TDOB01

- Brand: Honeywell

- Series: Central Control / DCS I/O Modules

- Product Type: Digital Output Module

- Key Features:

- Provides reliable digital output control for DCS systems

- Compatible with Honeywell Experion® PKS and other industrial control platforms

- Industrial-grade design ensures continuous operation under harsh conditions

- Simplifies integration of digital actuators and field devices into process control systems

Industrial Applications and Context

Digital output modules play a critical role in modern process automation, enabling precise control of valves, relays, pumps, and other actuators. Industries such as oil & gas, petrochemical, power generation, water treatment, and manufacturing rely on digital outputs to execute automated process sequences accurately and safely.

The Honeywell CC-TDOB01 provides a highly reliable interface between DCS systems and field devices, ensuring that control commands are executed promptly and accurately. Its robustness and flexibility make it suitable for continuous industrial operation, supporting plant efficiency, safety, and operational uptime.

- TDOB01

Role of the Honeywell CC-TDOB01

The CC-TDOB01 functions as a centralized digital output interface within industrial automation networks. Its primary roles include:

- Digital Signal Output: Sends control signals to actuators, solenoids, relays, and other field devices

- Process Execution: Enables precise operation of valves, motors, and safety interlocks based on DCS commands

- System Integration: Ensures seamless communication with Honeywell Experion® PKS or compatible control platforms

- Diagnostics: Provides real-time module status and fault detection for predictive maintenance

- Redundant and Critical Loop Support: Supports critical applications where continuous digital output is essential

By reliably transmitting control signals, the CC-TDOB01 ensures safe, efficient, and automated process operation.

Technical Features and Benefits

Core Features

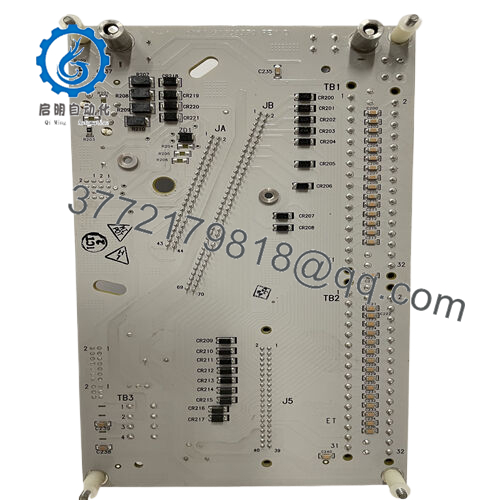

- Digital Output Channels: High-speed, isolated outputs compatible with a wide range of industrial actuators

- Industrial-Grade Reliability: Resistant to vibration, temperature extremes, and electrical noise

- DCS Compatibility: Integrates seamlessly with Honeywell Experion® PKS and other DCS platforms

- Signal Isolation: Maintains signal integrity and protects the system from noise or interference

- Diagnostics: Online status monitoring and fault detection for preventive maintenance

- Flexible Mounting: Supports panel, rack, or DIN rail installations

- Hot-Swap Ready: Can be replaced without significant disruption in supported configurations

Benefits

- Precise Process Control: Ensures reliable operation of digital actuators and field devices

- Operational Safety: Maintains signal integrity to prevent misoperation of critical equipment

- Reduced Downtime: Diagnostics and hot-swap capabilities allow for quick maintenance without halting operations

- Versatility: Compatible with various field devices, including solenoids, relays, and motors

- Ease of Integration: Simplifies connection and operation within central control systems

Technical Specifications

| Specification | Details |

|---|---|

| Model | Honeywell CC-TDOB01 |

| Type | Digital Output Module |

| Series | Central Control / DCS I/O Modules |

| Function | Sends digital control signals to actuators and field devices |

| Output Channels | Multiple high-speed isolated digital outputs |

| Communication | Compatible with Honeywell Experion® PKS bus and DCS protocols |

| Protection | Electrical isolation, surge protection, short-circuit protection |

| Mounting | Panel, rack, or DIN rail |

| Applications | Oil & gas, petrochemical, power generation, water treatment, manufacturing |

| Diagnostics | Online status monitoring, fault detection, predictive alerts |

Applications Across Industries

- Oil & Gas: Controls solenoid valves, pumps, and safety interlocks in pipelines and processing units

- Petrochemical Processing: Operates automated valves, mixers, and reactor control actuators

- Power Generation: Controls turbine auxiliaries, boiler valves, and critical safety interlocks

- Water & Wastewater Treatment: Manages pump and valve operations, chemical dosing, and alarms

- Manufacturing: Automates machinery operation, conveyors, and production line actuators

The CC-TDOB01 ensures accurate, reliable, and continuous digital control, essential for complex industrial processes.

Installation and Maintenance Insights

Installation Guidelines:

- Install in a vibration-free and temperature-stable environment

- Connect output channels according to Honeywell wiring and configuration standards

- Ensure proper grounding and shielding to prevent electrical noise interference

- Verify integration with DCS control loops and conduct functional testing before commissioning

Maintenance Tips:

- Regularly monitor module diagnostics to detect early signs of faults

- Inspect connections, terminals, and cables for corrosion or wear

- Replace modules during scheduled maintenance to minimize operational disruption

- Update firmware and configuration settings as recommended by Honeywell

Related Honeywell Modules

- Honeywell CC-TAON01: Temperature analog output module for process control

- Honeywell CC-PAON01: Pressure analog output module for DCS integration

- Honeywell CC-PUIO01: Universal I/O module for analog and digital signals

- Honeywell CC-PCNT02: Pulse counting module for process monitoring

- Honeywell FC-PUiO01: Field I/O module for decentralized process control

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626