Description

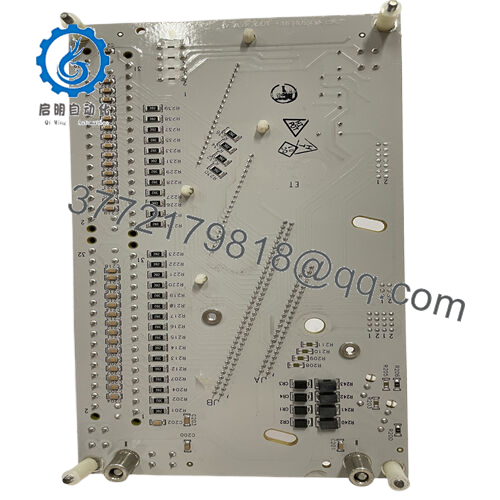

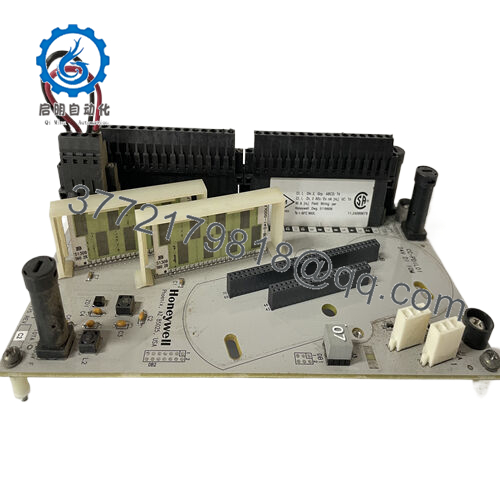

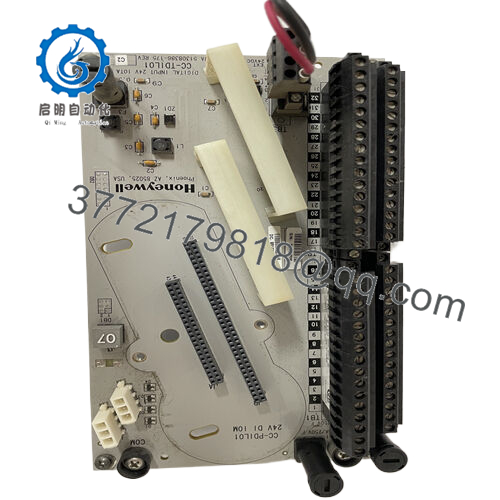

HONEYWELL CC-TDIL01 is a digital input module designed specifically for industrial control systems. It is part of Honeywell’s comprehensive product line aimed at improving industrial automation efficiency and reliability. This module has been carefully designed to interface with various field devices such as sensors and switches, and convert their digital signals into a format that is easy for the central control system to process.

CC -TDIL01

In Honeywell’s control system architecture,CC-TDIL01 is perfectly compatible with the IOTA (Integrated Operating Terminal Architecture) system. As a front-end interface for digital input signals, it provides a reliable and accurate way of data acquisition. Engineers and system integrators value CC-TDIL01 because of its simple integration and ability to handle large amounts of digital input signals. It can be easily configured to meet the specific requirements of different industrial applications, whether they are small manufacturing units or large industrial complexes.

CC -TDIL01

Main features and advantages:

Rich input channels

CC-TDIL01 is equipped with 32 digital input channels, which can interface with a large number of on-site devices simultaneously. This high channel count is particularly advantageous in complex industrial environments that require monitoring numerous sensors and switches. For example, in large chemical plants, there may be hundreds of sensors used for temperature, pressure, and flow measurement, as well as safety switches. The 32 channel capacity of CC-TDIL01 enables it to handle a large number of inputs, reducing the need for multiple modules and simplifying the overall system design.

Electrical isolation for signal integrity

This module has an electrical isolation level of 1500 VAC rms or ± 1500 VDC (relative to any input voltage of the common terminal), providing excellent electrical interference protection. This isolation method using optical isolation technology (in input/output modules) ensures that external electrical noise does not interfere with the received digital signal. In industrial environments, electromagnetic interference generated by motors, transformers, and other electrical equipment is common, and this isolation function is crucial for maintaining the accuracy and reliability of input data. It can prevent misreading and ensure that the control system receives correct information from on-site devices.

Accurate signal detection

This module is designed to accurately detect on and off status signals. For on state detection, it requires a voltage range of 18 to 30 VDC or a minimum current of 13 VDC or 3 mA. For off state detection, its maximum voltage is 5 VDC or 1.2 mA. This precise signal detection capability allows it to distinguish between valid and invalid signals even in challenging electrical environments. During the manufacturing process where sensors may be affected by voltage fluctuations or electrical transients, CC-TDIL01 can still accurately determine the status of the monitored equipment.

low-power consumption

At 24 VDC voltage, the current consumption of CC-TDIL01 is 0.190 amperes, which has energy-saving characteristics. This low power consumption not only helps to reduce the overall energy cost of industrial installations, but also helps to reduce heat generation. In control panels, space is usually limited, and reducing heat is crucial for maintaining optimal operating temperatures for all components. The energy-saving design of this module ensures its continuous operation without overheating, improving its reliability and service life.

Compatibility with Honeywell systems

CC-TDIL01 is highly compatible with Honeywell’s TDC (Fully Distributed Control) system, especially TDC 2000 and TDC 3000. It may also be compatible with Honeywell’s Expert system. This compatibility enables seamless integration in existing Honeywell based industrial control settings. For companies that have already invested in Honeywell control infrastructure, CC-TDIL01 can be easily added or replaced as needed without the need for large-scale system modifications. It ensures that the new module can effectively communicate with other components of the control system, maintaining overall operational integrity and efficiency.

CC -TDIL01

Technical specifications:

Model CC-TDIL01

Brand HONEYWELL

Type number input module

Voltage 24 VDC

System compatibility IOTA (Integrated Operating Terminal Architecture), TDC 2000, TDC 3000 (possibly compatible with the Expert ion system)

Redundancy non redundancy (redundancy version CC – TDIL1)

The size is estimated based on similar modules, with a height of approximately 9 inches

Current consumption 0.190 amperes @ 24 VDC

Heat dissipation 4.220 watts

Input channel 32

Electrical isolation 1500 VAC rms or ± 1500 VDC

Isolation technology optics (in input/output modules)

On state voltage/current 18 to 30 VDC, 13 VDC (minimum) or 3 mA (minimum)

Off state voltage/current 5 VDC (maximum) or 1.2 mA (maximum)

The absolute delay of the input filter and isolator is 4.2 k Ω

Ensure on-site resistance of 300 Ω maximum @ 15 VDC in the off state

Transport weight 2 kilograms

Product origin: United States

contact us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

CC -TDIL01

Application areas:

In the oil and gas industry, refineries are equipped with a large number of valves, pumps, and compressors. CC-TDIL01 is used to monitor the status of these devices. It can detect whether the valve is open or closed, whether the pump is running or stopped, and the digital outputs of pressure and temperature sensors. For example, in the distillation unit of a refinery, it continuously monitors the status of control valves used to regulate the flow of crude oil and its by-products. By providing real-time data on equipment status, it enables operators to make informed decisions, optimize refining processes, and prevent potential equipment failures.

Power plants are also highly dependent on CC-TDIL01. In thermal power plants, it can monitor the status of generators, boilers, and cooling systems. It reads digital signals from sensors that detect boiler water temperature, turbine speed, and circuit breaker status. These pieces of information are crucial for maintaining the stable operation of power plants. If the sensor detects an abnormal increase in boiler temperature, CC-TDIL01 will immediately send this information to the control system to take timely measures to prevent overheating and potential disasters.

Related products:

HONEYWELL CC-TDIL11: This is a redundant version of CC-TDIL01. In applications that require high availability, such as power plants or critical manufacturing processes, CC-TDIL11 can be used. It provides an additional layer of protection for module failures, ensuring the continuous operation of the control system. If CC-TDIL01 malfunctions, CC-TDIL11 can seamlessly take over the digital input function.

HONEYWELL C300 Controller: CC-TDIL01 can be integrated with HONEYWELL C300 Controller. The controller receives digital input signals processed by CC-TDIL01 and uses this information to make control decisions. For example, in industrial process control systems, the C300 controller may adjust the motor speed or valve position based on the input signal of CC-TDIL01.

HONEYWELL FTE cables: These cables are used to establish high-speed and reliable communication links between CC-TDIL01 and other components of the control system. They ensure accurate and timely transmission of digital input data. In large industrial networks, FTE cables are capable of processing a large amount of data generated by the 32 input channels of CC-TDIL01, ensuring the smooth operation of the entire control system.

HONEYWELL CC – PDOB01: This is a digital output module. CC-TDIL01 is responsible for receiving digital input signals, while CC-PDOB01 can be used in conjunction with it to send digital control signals to actuators and other output devices. In industrial automation settings, CC-TDIL01 may detect the status of sensors, and the control system can use CC-PDOB01 to activate the corresponding actuators, such as solenoid valves or relays.

Installation and maintenance:

Considerations before installation

Power verification: Before installation, it is necessary to verify whether the available power supply of CC-TDIL01 is a stable 24 VDC power supply. Check for voltage fluctuations or electrical noise in the power cord. If necessary, use a power regulator to ensure a clean and stable power supply. Incorrect power supply may cause module malfunction and inaccurate signal reading.

Cable routing and termination: Carefully plan cable routing. Due to the fact that CC-TDIL01 has 32 input channels, multiple cables will be connected to it. Ensure that the cable routing method can minimize electromagnetic interference to the greatest extent possible. Use shielded cables to better resist external electrical noise. When terminating cables, strictly follow the manufacturer’s guidelines to ensure correct electrical connections. Loose or incorrect cable termination may result in signal loss or misreading.

Environmental assessment: Evaluate the installation environment. CC-TDIL01 is designed to operate in industrial environments, but extreme conditions such as high humidity, excessive dust, or strong vibrations may still affect its performance. If the installation location is in a particularly harsh environment, consider using additional protective enclosures or taking measures to mitigate the impact of environmental factors. For example, in dusty factories, modules are installed in sealed enclosures with appropriate ventilation to prevent dust from accumulating on the modules.

Maintenance Guide

Regular visual inspection: Conduct regular visual inspections on CC-TDIL01. Check for any signs of physical damage, such as cracked casing, loose connectors, or signs of overheating. Check the status indicator lights on the module (if any) to ensure they are functioning properly. Visual inspection helps to detect potential issues early and prevent more serious problems from occurring.

Signal integrity testing: Regularly test the signal integrity of the input channel. Use a signal generator to send known digital signals to the input channel and verify that the module accurately reads and transmits these signals to the control system. This test can be conducted using diagnostic tools provided by Honeywell or third-party testing equipment. If any channel readings are found to be incorrect, further investigation is needed to determine the cause, which may be a cable malfunction, a problem with the sensor connected to that channel, or an issue with the module itself.

Firmware Update: Stay up-to-date with the latest firmware versions released by Honeywell. These updates typically include error fixes, performance improvements, and enhanced compatibility with other control system components. When updating firmware, strictly follow the manufacturer’s instructions to avoid interference with the control system. In some cases, firmware updates may be necessary to address specific issues discovered during module operation.

Spare parts management: If CC-TDIL01 is used for critical applications, please reserve spare parts. This includes spare modules, replacement cables, and connectors. Reserve spare parts can significantly reduce downtime in the event of module failure. Regularly check the condition of spare parts to ensure they are in a usable state.

HONEYWELL related products:

HONEYWELL 2104B2071

HONEYWELL 10012/1/2

HONEYWELL 05701-A-0550

Honeywell 1569905-6131140220

HONEYWELL 05701-A-0351

Honeywell SPS5710 51199929-100

Honeywell QPP-002

Honeywell WEB-600E

HONEYWELL 05701-A-0302

HONELYWELL 900C75-0560

HONEYWELL MC-PDOY22

Honeywell PCNT02

Honeywell TK-PRS021 51404305-375

Honeywell TK-PRR021 51309288-275

Honeywell TK-IOLI01 51403427-175

Honeywell СС-PWRR01

Honeywell FC-PUIO01

Honeywell CC-TUI041

Honeywell TC-IAH161

Honeywell FC-SAO-0220M

Honeywell CC-SCMB02

Honeywell FC-FANWR-24R

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626