Description

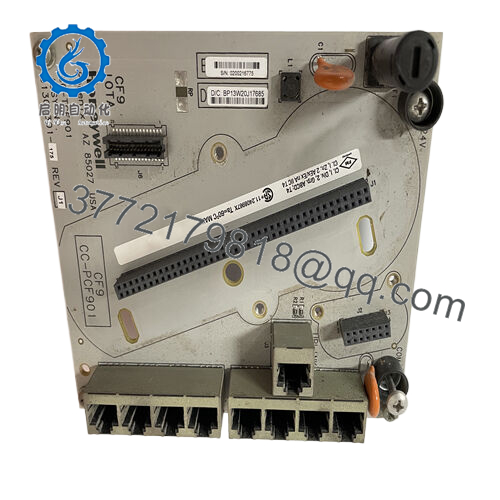

HONEYWELL CC-TCF901 is an advanced control firewall input/output terminal component (IOTA). As part of Honeywell’s advanced industrial automation solutions, it combines the dual functions of ensuring network security and facilitating seamless data transmission within control systems.

CC-TCF901

This module is designed to become a part of larger control architectures, such as Honeywell’s Expert ® Or other compatible distributed control systems. It serves as a bridge between different segments of the control network, with a particular focus on protecting critical control domains. For example, it can be used to connect controllers inside cabinets and CFIM series FTE cables.

Engineers and integrators value the ability of CC-TCF901 to enhance the security posture of control systems without sacrificing performance. It provides a comprehensive set of security features, including traffic prioritization. It prioritizes processing inbound traffic from downstream ports over upstream ports, ensuring that critical control instructions are not delayed. In addition, it only allows valid C300 compatible messages to pass through to the C300 domain, adding an additional layer of security.

CC-TCF901

Main features and advantages:

Network topology flexibility

CC-TCF901 stands out for supporting multiple fiber network topologies. It can handle logically independent dual bus electrical interfaces, point-to-point networks, and dual optical port chain networks. This flexibility means that it can be customized for different application scenarios and needs. This module can be configured for both large industrial factories with complex network infrastructure and smaller facilities with simpler structures.

Redundant design improves reliability

CC-TCF901 adopts a dual optical port design, which realizes the redundancy function of dual fiber ring network. In the event of a fiber optic failure, the system can quickly rebuild the network link within just 10 milliseconds. This redundant design is a game changing factor for industries that require continuous operation, as it significantly improves the overall reliability and stability of the control system.

Multiple interface options

CC-TCF901 is equipped with multiple interface types, such as RJ-45 and FTE monitoring network interface, which simplifies the connection and communication process with other devices and systems. This compatibility allows seamless integration into existing industrial automation settings, reducing the need for complex and expensive custom interfaces.

High reliability in harsh environments

CC-TCF901 is designed to withstand harsh conditions in industrial environments and can operate within a temperature range of -40 ° C to+85 ° C. Its sturdy structure and design enable it to resist strong electromagnetic interference, ensuring reliable operation even in the presence of noisy electrical equipment. This high reliability is crucial for maintaining the integrity of control systems in harsh industrial environments.

CC-TCF901

Technical specifications:

ModelCC-TCF901

Brand HONEYWELL

Type Control Firewall Input/Output Terminal Component (IOTA)

Power supply 24V DC (some materials also mention other specified voltage ranges)

Working temperature -40 ° C to+85 ° C

Installation method: DIN rail installation or panel installation (depending on the design)

Size 50mm × 90mm × 87mm

Weight 1 kilogram (approximately, transportation weight may vary, such as 2 kilograms)

Input/Output Type Number

Communication protocol Modbus TCP/IP (as well as other protocols that may be supported within the Honeywell ecosystem)

Environmental grade resistant to strong electromagnetic interference, suitable for harsh industrial environments

Port 9 RJ-45 connections (8 for FTE connection with C300 and C-series FIMs in C-series cabinets, 1 for uplink connection to monitoring FTE network and secondary control area)

Electrical isolation between isolated communication ports and other system components

contact us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

CC-TCF901

Application areas:

In the energy sector, such as refineries and power plants, critical infrastructure control systems are the main targets of cyber attacks. CC-TCF901 is like a vigilant sentinel, protecting the communication channel between on-site equipment and the central control room. For example, in a refinery, it ensures the data flow security of thousands of sensors monitoring parameters such as temperature, pressure, and flow in pipelines and storage tanks. In this way, it can prevent unauthorized access and avoid operational interruptions that may lead to security incidents and significant economic losses.

The manufacturing industry is also highly dependent on CC-TCF901. In automobile manufacturing factories, complex robot systems and automated assembly lines are controlled by precise networks, and any security vulnerabilities can lead to production stagnation. This module ensures that digital commands sent to control robotic arms, conveyors, and other devices are protected. It filters out malicious traffic and only allows legitimate control signals to pass through, thus maintaining the smooth progress of the production process.

Pharmaceutical manufacturing is another field where CC-TCF901 plays an important role. Due to strict regulatory requirements for product quality and safety, the control systems of these facilities must not experience any interruptions. This module protects the communication between sensors and actuators in the cleanroom environment, ensuring precise control of temperature, humidity, and pressure. This not only helps prevent cyber threats, but also helps maintain the integrity of the drugs produced.

Related products:

HONEYWELL CC-TCF902- With enhanced security features, it may provide more advanced intrusion detection capabilities, suitable for applications with higher security requirements.

HONEYWELL CC-PDIL01- Digital Input Module, compatible with CC-TCF901. It can provide additional digital input channels for the control system and expand its data collection capabilities under the protection of the firewall module.

HONEYWELL CC-PDOB01- Digital output module, can be integrated with CC-TCF901. It enables the control system to send digital control signals to actuators and other devices, and the security provided by the firewall module ensures the integrity of these instructions.

HONEYWELL CC-PCMM01- Communication module that enhances the connectivity of CC-TCF901. It enables modules to communicate with a wider range of devices and systems through different network protocols, expanding the overall coverage and functionality of the control system.

HONEYWELL CC-PWRM01- Power module ensures stable power supply for CC-TCF901. In industrial environments, power fluctuations may be a problem, and this module helps maintain the reliable operation of firewall modules.

HONEYWELL CFIM series FTE cables – These cables are directly compatible with CC-TCF901. They are used to establish the physical connections required for module communication within the control network, ensuring high-speed and reliable data transmission.

HONEYWELL C300 Controller – CC-TCF901 is designed to work closely with the C300 controller. It protects the communication channels entering and exiting these controllers, ensuring the security and accuracy of control commands and data.

Installation and maintenance:

Considerations before installation:

Network planning: Thoroughly plan the network layout before installing CC-TCF901. Determine the location of the devices to be connected to the module and ensure that the selected network topology (such as dual bus or point-to-point) is suitable for the application. Simultaneously consider future expansion plans, as the flexibility of this module allows for easy reconfiguration.

Power compatibility: Verify whether the power supply installed on site meets the requirements of CC-TCF901. Check voltage stability and ensure that there are no significant fluctuations that may affect module performance. If necessary, use a power regulator to stabilize the power supply.

Physical installation: Select the appropriate installation location for the module. If using DIN rails for installation, ensure that the rails are securely installed and there is sufficient space around to allow for proper ventilation. For panel installation, ensure that the panel is sturdy and easy to maintain in the future.

Maintenance Guide:

Regular visual inspection: Conduct regular (such as monthly) visual inspections of modules. Look for any signs of physical damage, loose connections, or overheating. Check the status indicator lights on the module to ensure they are functioning properly.

Firmware Update: Stay up-to-date with Honeywell’s latest firmware releases. These updates typically include security patches, bug fixes, and performance improvements. Schedule firmware updates at least once a year and ensure careful adherence to the manufacturer’s instructions to avoid any interruptions to the control system.

Network monitoring: Continuously monitor network traffic through CC-TCF901. Use network monitoring tools to detect any abnormal behavior, such as unauthorized access attempts or excessive data traffic. Set up alerts to immediately notify maintenance teams in the event of any security threats.

HONEYWELL related products:

HONEYWELL 2104B2071

HONEYWELL 10012/1/2

HONEYWELL 05701-A-0550

Honeywell 1569905-6131140220

HONEYWELL 05701-A-0351

Honeywell SPS5710 51199929-100

Honeywell QPP-002

Honeywell WEB-600E

HONEYWELL 05701-A-0302

HONELYWELL 900C75-0560

HONEYWELL MC-PDOY22

Honeywell PCNT02

Honeywell TK-PRS021 51404305-375

Honeywell TK-PRR021 51309288-275

Honeywell TK-IOLI01 51403427-175

Honeywell СС-PWRR01

Honeywell FC-PUIO01

Honeywell CC-TUI041

Honeywell TC-IAH161

Honeywell FC-SAO-0220M

Honeywell CC-SCMB02

Honeywell FC-FANWR-24R

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626