Description

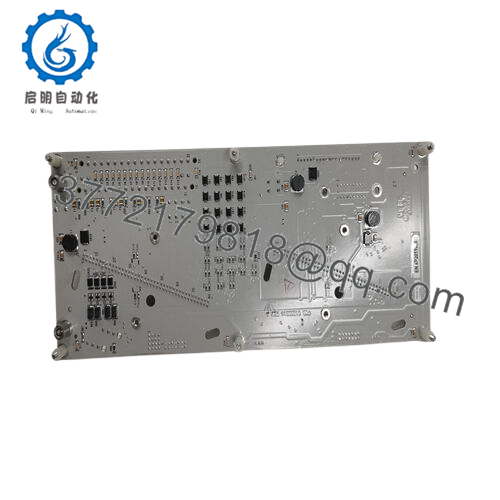

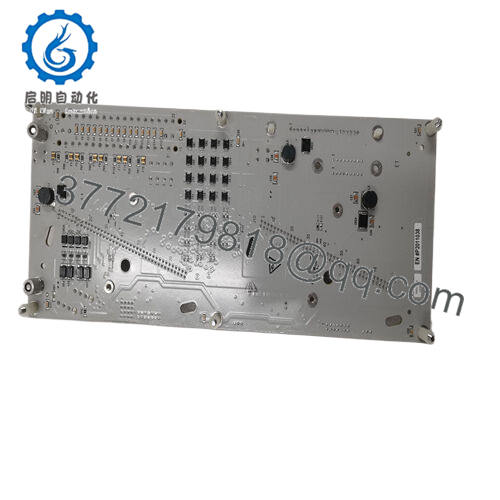

The Honeywell CC-TAIN11 is an analog input module designed as a key component of Honeywell’s Experion Process Knowledge System (PKS), one of the industry’s leading distributed control platforms. Functionally, it serves as the critical link between field sensors and the system’s control processors, specializing in converting raw analog signals (like 4-20mA current or 0-10V voltage) into digital data that the PKS can analyze and act upon.

CC-TAIN11

In control system architecture, the Honeywell CC-TAIN11 resides in the I/O subsystem, typically mounted in a rack alongside other interface modules. It acts as the “ears” of the system, capturing continuous process variables from sensors measuring temperature, pressure, level, or flow. What makes it valuable for engineers is its ability to handle multiple signal types without requiring hardware reconfiguration—saving time during setup and allowing for flexible system modifications. Integrators appreciate its plug-and-play compatibility with Honeywell’s C300 controllers and Series 8 I/O racks, reducing integration complexity in both new installations and retrofits of legacy systems.

CC-TAIN11

Main features and advantages:

CC-TAIN11

Technical specifications:

Model CC-TAIN11

Brand Honeywell

Type Analog Input Module

Power Supply 24V DC ±10%

Operating Temperature -40°C to 70°C (-40°F to 158°F)

Mounting 19-inch rack mount (3U height)

Dimensions 160mm (W) x 130mm (H) x 220mm (D)

Weight 1.2kg (2.65 lbs)

Interfaces 16 differential analog inputs (4-20mA, 0-10V, thermocouple, RTD)

Certifications IEC 61010-1, ATEX Zone 2, UL 61010, CE

Cooling Forced air via rack-mounted fans

Environmental Rating IP20 (front panel), NEMA 1 when installed in enclosure

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

CC-TAIN11

Application areas:

In the high-pressure environments of chemical processing plants, where even the smallest data transmission delay can lead to hazardous pressure fluctuations, the Honeywell CC-TAIN11 stands as a critical communication bridge. Imagine a facility producing specialty polymers, where precise control of reaction temperatures and catalyst flow rates determines product quality. Here, the Honeywell CC-TAIN11 connects dozens of thermocouples, flow meters, and control valves to the central DCS, ensuring that readings from the reactor core reach operators in milliseconds. This instant data flow allows for immediate adjustments when viscosity or pH levels drift from optimal ranges, preventing batch failures that could cost tens of thousands of dollars.

Similarly, in automotive assembly plants, where robotic welding arms must synchronize with conveyor systems to maintain production Rhythm, the Honeywell CC-TAIN11 excels at translating analog position signals from linear encoders into digital commands that keep the line moving. When a sensor detects a misaligned chassis, the module rapidly communicates the deviation to the main controller, triggering an automatic slowdown before a collision occurs. Used in industrial automation across sectors from food and beverage to pulp and paper, the Honeywell CC-TAIN11has become indispensable in systems where reliable signal conversion directly impacts safety, efficiency, and bottom-line performance. Its ability to thrive in electrically noisy environments—common near large motors or high-voltage equipment—makes it a preferred choice for integrators designing robust control architectures.

Related products:

Other Honeywell product models:

HONELYWELL 05701-A-0361

HONEWELL 05704-A-0145

HONELYWELL 900C75-0560

HONEWELL 2MLI-CPUU

HONELYWELL CC-PPIX01

HONELYWELL 5701-A-0361

HONEWELL C7012E1112/U

HONEWELL CC-PWRR01

HONEWELL CC-PDOB01

HONEWELL CC-TDOB01 51308371-175

HONELYWELL FC-QPP-0002

HONELYWELL FC-QPP-0002

HONELYWELL FC-QPP-0002

HONELYWELL 51301874-100

HONELYWELL 51196694-904

HONEWELL 80363969-150

HONEWELL FC-USI-0002

HONELYWELL CC-PUIO31

HONELYWELL CC-PUIO01

HONELYWELL CC-TUIO01

HONELYWELL CC-PWR401

HONELYWELL CC-PFB401

HONELYWELL FC-PSU-UNI2450U

HONELYWELL FC-TSRO-0824

HONELYWELL FC-RUSIO-3224

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626