Description

The Honeywell CC-PUIO31 is widely deployed in industrial automation, especially within process control environments such as chemical plants, oil refineries, power generation facilities, and manufacturing sites that demand precise monitoring and control of field devices. It is applicable in control systems requiring versatile input/output configurations to interface with a broad spectrum of analog and digital signals. This universal I/O module addresses the challenge of integrating diverse field instrumentation, including sensors, actuators, and communication devices, into centralized control architectures.

Industries benefit from the Honeywell CC-PUIO31 where flexible channel configuration is crucial, as it allows adaptation to changing process requirements without hardware replacement. It supports complex signal types like digital inputs, outputs, analog signals, pulse inputs, and sequencing of event data, making it ideal for environments needing comprehensive data acquisition and real-time response. The module’s ability to function safely in hazardous locations with robust electronic short-circuit protection further underscores its suitability for demanding industrial settings.

This module lends itself to applications requiring enhanced system uptime and responsiveness through features like fast scanning and safe-state outputs. It is an indispensable component in automation schemes that prioritize safety, reliability, and seamless communication across control layers.

- CC-PUIO31

Product Introduction and Positioning

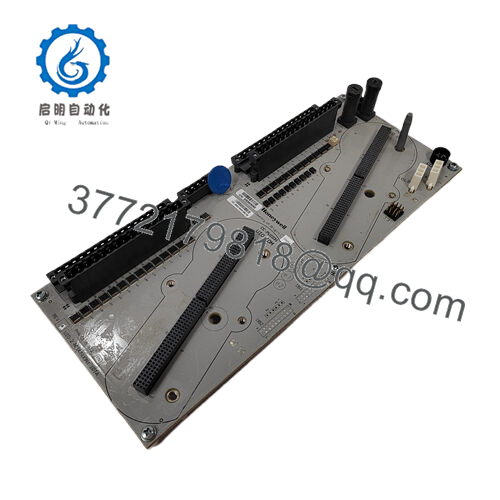

The Honeywell CC-PUIO31 is a universal input/output module designed for use within Honeywell’s Experion Series C300 Distributed Control System (DCS). It functions as a versatile interface that consolidates different types of analog and digital signals into a single flexible module, streamlining system architecture and reducing inventory complexity. This multi-functional module fits within the Experion platform’s expansive I/O system and supports process automation tasks by managing signals from the field to the controller efficiently.

Positioned as a core hardware element, the CC-PUIO31 enables engineers and system integrators to configure up to 32 channels per module according to specific process needs, covering analog input/output, digital input/output, pulse input, and event sequencing. Its design is compatible with the larger Series C control hardware ecosystem, integrating with controllers, communication modules, and supervisory systems seamlessly.

What makes the CC-PUIO31 particularly valuable is its support for advanced features such as HART 7 protocol compatibility and fast scan prioritization, lending enhanced communication capability and improved control cycle times. It is tailored for industrial applications demanding high system availability and flexible control infrastructure.

Key Technical Features and Functional Benefits

The Honeywell CC-PUIO31 stands out through its user-configurable universal channels, offering up to 32 inputs or outputs that can be set as analog, digital, or pulse types based on application requirements. This flexibility optimizes system design by replacing multiple specialized modules with a single adaptable solution. Each channel supports precise data capture and control due to 16-bit resolution for analog signals, ensuring accurate measurement and response.

Its robust hardware design includes electronic short-circuit protection that safeguards both the module and other connected channels against faults in the field, enhancing operational safety and reliability. The module operates smoothly over an extended temperature range (-40 to +70°C), confirming its suitability for harsh industrial environments. Compact and designed for standard panel mounting, it integrates efficiently into existing control hardware setups.

Compatibility with the Honeywell Experion Series C controller and support for HART 7 communication provides a reliable interface for digital smart field devices, promoting advanced diagnostics and parameter adjustments. Fast scan functionality prioritizes module polling within the system, ensuring rapid updating of critical I/O data and boosting control system responsiveness.

In terms of long-term reliability, the CC-PUIO31 is engineered for high availability with redundant configurations available, reducing risks of downtime. Safe state output configuration allows predefined fail-safe conditions per channel, adding an essential layer of process safety management.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | CC-PUIO31 |

| Brand | Honeywell |

| Product Type | Universal Input/Output Module |

| Channel Count | Up to 32 configurable channels |

| Input Types | Analog, Digital, Pulse |

| Output Types | Analog, Digital |

| Signal Resolution | 16-bit (analog) |

| Operating Temperature | -40 to +70 °C |

| Mounting | Standard panel mounting |

| Protection | Electronic short-circuit protection |

| Communication Support | HART 7 protocol |

| Safe State Configuration | Per channel configurable |

| Redundancy Options | Available (CC-TUIO41 redundant) |

Related Modules or Compatible Units

CC-TUIO31 – Non-redundant version of the universal I/O module, optimized for standard reliability needs.

CC-TUIO41 – Redundant universal I/O module variant offering enhanced system availability.

FS-TSDO-0824 – Digital output connection module designed to complement the CC-PUIO31.

CC-PCNT01 – Core controller module within the Honeywell Experion Series C platform supporting control and communication.

CC-PFB801 – Fieldbus interface module compatible with Series C controls enabling network communications.

Installation Notes and Maintenance Best Practices

Before installation, ensure the control panel or cabinet space accommodates the Honeywell CC-PUIO31 module and that environmental conditions such as temperature and humidity comply with the specified operating range. Proper grounding and shielding of signal wiring are essential to minimize electromagnetic interference, especially in industrial environments with heavy electrical noise. Adequate clearance around the module facilitates heat dissipation and prevents thermal stress, supporting reliability over time.

Regular maintenance involves periodic visual inspection for dust accumulation, corrosion, or loose connections and monitoring system diagnostics for potential communication or signal anomalies. Field wiring should be checked for integrity, especially in hazardous or high-vibration zones. Firmware updates recommended by Honeywell should be applied to maintain operational efficiency and compatibility with evolving system requirements.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626