Description

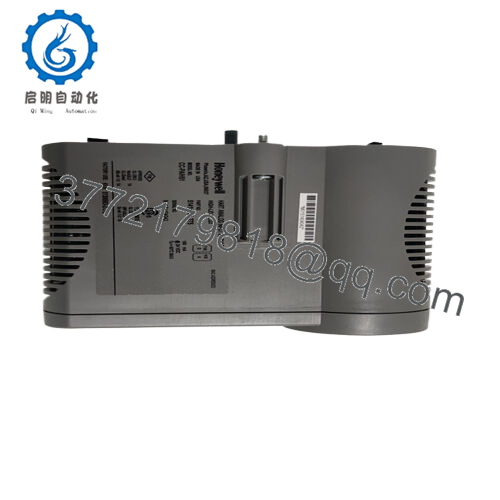

The Honeywell CC-PAIH51 serves as a vital linchpin between field sensors and the overarching control system. It is expertly crafted to convert a vast array of raw analog signals from various sensors, including those measuring pressure, temperature, flow, and level, into digital data that can be effortlessly processed by high-level controllers. This module is optimized for seamless integration with Honeywell’s flagship Experion PKS and TPS systems. Leveraging the industry-standard ControlNet backplane, it enables smooth and uninterrupted communication within the complex automation infrastructure. One of the standout features of the Honeywell CC-PAIH51 is its cutting-edge signal conditioning technology. It is equipped with advanced algorithms and hardware filters that can effectively eliminate electrical noise, ensuring that the data transmitted to the control system is stable, accurate, and free from interference. This is of utmost importance in applications where precise process control is non-negotiable, such as in pharmaceutical manufacturing where strict quality control standards must be met. Additionally, the module supports redundant configurations, a critical feature for industries where downtime is unacceptable. In the event of a primary module failure, it can automatically switch to a backup module, ensuring continuous operation and minimizing the risk of costly production disruptions. The Honeywell CC-PAIH51also comes with an integrated diagnostic system that constantly monitors its own health and the quality of incoming signals. Through real-time alerts sent to the control system, maintenance teams can be proactively informed of any potential issues, allowing them to take preventive measures and address problems before they escalate into major failures. This combination of seamless integration, advanced signal processing, and intelligent diagnostics positions the Honeywell CC-PAIH51 as a cornerstone of reliable and high-performance industrial control systems.

CC-PAIH51

Technical specifications:

Model NumberCC-PAIH51

Brand Honeywell

TypeAdvanced Analog Input Module

Operating Temp Range-45°C to 75°C (-49°F to 167°F)

Mounting StyleRack-mounted (19-inch standard)

Interface/BusControlNet

ComplianceCE, RoHS, UL 508

Supported ProtocolsHART, Modbus RTU (via gateway)

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

CC-PAIH51

Main features and advantages:

CC-PAIH51

Application areas:

The Honeywell CC-PAIH51 truly shines in industries where the integrity of analog signals is of paramount importance for safety and efficiency. In power generation plants, it can simultaneously monitor a large number of critical parameters such as steam pressure, turbine temperature, and generator load, providing the precise data required to optimize power generation, prevent equipment overheating, and ensure grid stability. In chemical processing facilities, it can handle sensor inputs from highly corrosive environments, accurately measuring reactor pressure, chemical composition, and flow rates – measurements that directly impact batch quality, production efficiency, and worker safety. In semiconductor manufacturing, where high precision is crucial for fabricating intricate chips, the Honeywell CC-PAIH51 can manage the complex analog signals involved in processes like lithography, etching, and wafer handling. Across all these applications, the module’s ability to handle high-density analog inputs while maintaining peak performance over extended periods of operation is invaluable, especially in scenarios where continuous uptime is essential to avoid costly shutdowns or non-compliant production runs.

CC-PAIH51

Related products:

CC-PAIH51

Installation and maintenance:

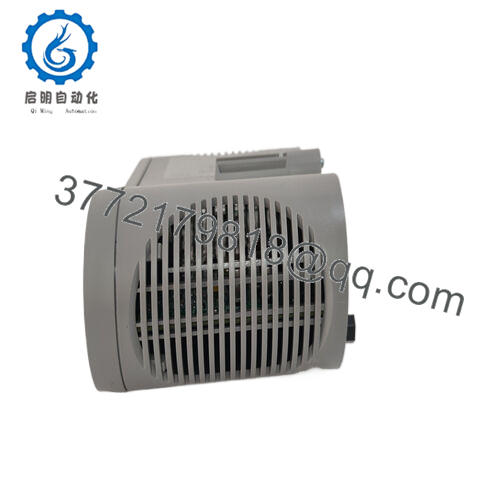

Before installing the Honeywell CC-PAIH51, it is essential to conduct a thorough compatibility check. Verify that the firmware of the target control rack is fully compatible with the module’s version. Refer to Honeywell’s official and regularly updated compatibility matrix for the most accurate and current requirements. Given the module’s high-performance capabilities, it is crucial to ensure that the mounting rack has sufficient cooling capacity. Due to its advanced processing and high-density design, the CC-PAIH51 may generate more heat than standard modules. It typically requires an ambient airflow of at least [X] m/s to maintain optimal operating temperatures, especially in high-heat industrial environments. Thoroughly inspect the ControlNet backplane connectors for any signs of damage, such as bent pins or corrosion. Poor contact in these connectors can lead to intermittent communication problems, which can disrupt the smooth operation of the entire system.

During installation, ensure that shielded wiring is used for analog inputs. This is a critical step in maximizing noise rejection, especially in environments with high electromagnetic interference.

For ongoing maintenance, it is recommended to establish a regular inspection schedule. Review the module’s status LEDs on a monthly basis. A steady green light indicates normal operation, while a flashing red light signals a fault that requires immediate attention. Conduct an annual calibration check to ensure that the input accuracy remains within the factory-specified limits. Although the module is equipped with advanced drift compensation features that help reduce the frequency of adjustments, regular calibration is still necessary to maintain peak performance. Additionally, regularly check the tightness of the input terminals to prevent connection loosening caused by vibration, which is particularly important in installations near heavy machinery or in environments with significant vibrations.

HONELYWELL Other product models:

HONELYWELL FC-QPP-0002

HONELYWELL 51301874-100

HONELYWELL 51196694-904

HONEWELL 80363969-150

HONEWELL FC-USI-0002

HONELYWELL CC-PUIO31

HONELYWELL CC-PUIO01

HONELYWELL CC-TUIO01

HONELYWELL CC-PWR401

HONELYWELL CC-PFB401

HONELYWELL FC-PSU-UNI2450U

HONELYWELL FC-TSRO-0824

HONELYWELL FC-RUSIO-3224

HONELYWELL FC-TSRO-08UNI

HONEWELL CC-PUI031

HONEWELL TP-DSOEP1-100

HONEWELL TP-OPADP1-200

HONELYWELL FC-IOCHAS-0001R

HONELYWELL FC-RUSIO-3224

HONEWELL NE-FWMB01

HONEWELL CC-PWRB01

HONELYWELL LG1093AA24

HONELYWELL CC-PUIO31

HONELYWELL FC-IO-0002

HONELYWELL FS-FEEDER-24R

HONEWELL 05704-A-0145

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626