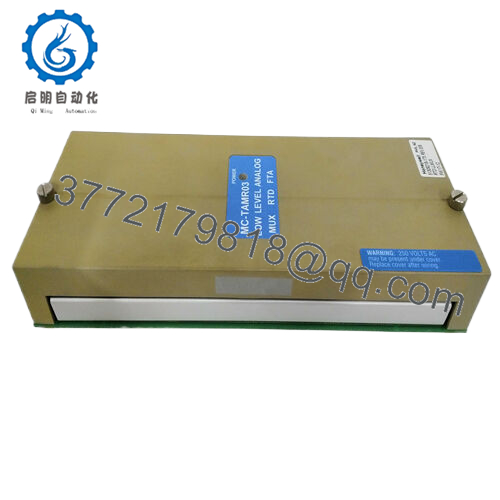

Description

The Honeywell 51309218-175 functions as a high – performance communication module in the industrial automation stack, acting as a vital link between various components of the control system. It is engineered to facilitate data exchange between different modules, controllers, and field devices, ensuring that information is transmitted accurately and in a timely manner. This module integrates smoothly with Honeywell’s Experion PKS and TDC 3000 control platforms, leveraging the system’s existing network infrastructure to enable efficient communication. One of its standout features is its support for multiple communication protocols, which allows it to interact with a wide range of devices, both new and legacy.

51309218-175

The Honeywell 51309218-175 also incorporates advanced error – correction mechanisms to minimize data loss and ensure the integrity of transmitted information, even in noisy industrial environments with high levels of electromagnetic interference.

51309218-175

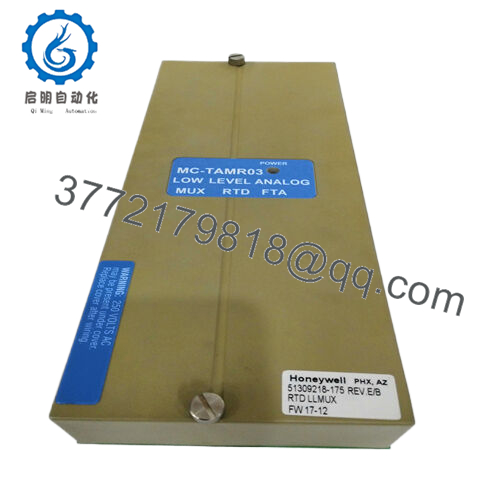

Technical specifications:

Model Number51309218-175

BrandHoneywell

TypeCommunication Interface Module

Input Voltage24V DC

Operating Temp Range- 10°C to 60°C

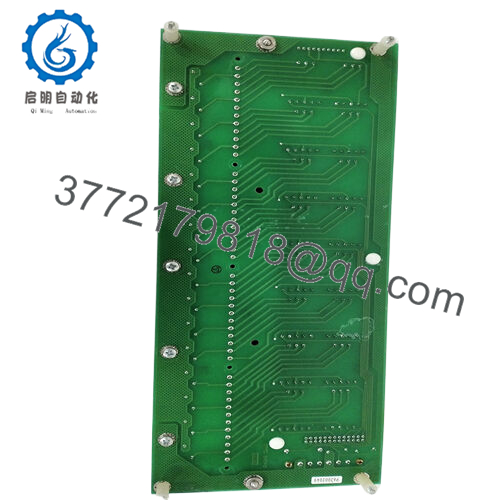

Mounting StyleBackplane – Mounted

Dimensions150mm x 100mm x 70mm

Weight400g

Interface/BusEthernet, Profibus DP

ComplianceCE, UL, RoHS

Supported ProtocolsModbus TCP/IP, Profinet, Ethernet/IP

Typical Power Draw6W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

51309218-175

Main features and advantages:

Redundancy is a crucial aspect in mission – critical industrial setups, and the Honeywell 51309218-175 is well – equipped to handle this need. It supports redundant communication paths, ensuring that if one path fails, data transmission can seamlessly switch to the backup path, preventing any disruption to the system. The module is equipped with comprehensive diagnostic features that continuously monitor its own performance, network connectivity, and data transmission status. These diagnostics provide real – time alerts through the control system interface, enabling engineers to quickly identify and resolve any communication issues before they escalate into major problems. Its design is optimized for easy installation and integration into existing control systems, reducing the complexity of system upgrades and expansions.

Opting for the Honeywell 51309218-175 brings a host of real – world benefits to industrial operations. Its robust design ensures long – term reliability, even in harsh industrial environments, reducing the need for frequent replacements and lowering maintenance costs. The module’s high – speed data transmission capabilities enable quick and efficient exchange of information, which is essential for real – time control applications where timely decisions are critical. This speed translates to improved process responsiveness, allowing the control system to adjust to changing conditions promptly. Additionally, the support for multiple protocols in the Honeywell 51309218-175eliminates the need for multiple communication modules, simplifying the system architecture and reducing engineering overhead during setup and configuration.

51309218-175

Application areas:

The Honeywell 51309218-175finds extensive application across various industrial sectors. In the oil and gas industry, it is used to facilitate communication between remote sensors in pipelines and the central control system, ensuring that operators have real – time data on pressure, flow, and temperature, which is vital for safe and efficient operations. In manufacturing facilities, the module enables seamless communication between robotic systems, conveyor belts, and the main control unit, optimizing production processes and maximizing throughput. In power generation plants, it plays a key role in connecting different subsystems, such as turbine controls and generator monitors, ensuring that all components work in harmony to maintain stable power output. The module’s ability to perform reliably in these diverse and demanding environments makes it a trusted choice for critical industrial systems.

Related products:

HONELYWELL Other product models:

HONELYWELL FC-QPP-0002

HONELYWELL 51301874-100

HONELYWELL 51196694-904

HONEWELL 80363969-150

HONEWELL FC-USI-0002

HONELYWELL CC-PUIO31

HONELYWELL CC-PUIO01

HONELYWELL CC-TUIO01

HONELYWELL CC-PWR401

HONELYWELL CC-PFB401

HONELYWELL FC-PSU-UNI2450U

HONELYWELL FC-TSRO-0824

HONELYWELL FC-RUSIO-3224

HONELYWELL FC-TSRO-08UNI

HONEWELL CC-PUI031

HONEWELL TP-DSOEP1-100

HONEWELL TP-OPADP1-200

HONELYWELL FC-IOCHAS-0001R

HONELYWELL FC-RUSIO-3224

HONEWELL NE-FWMB01

HONEWELL CC-PWRB01

HONELYWELL LG1093AA24

HONELYWELL CC-PUIO31

HONELYWELL FC-IO-0002

HONELYWELL FS-FEEDER-24R

HONEWELL 05704-A-0145

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626