Description

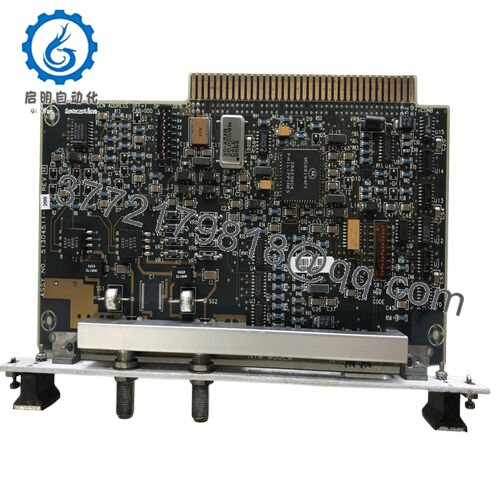

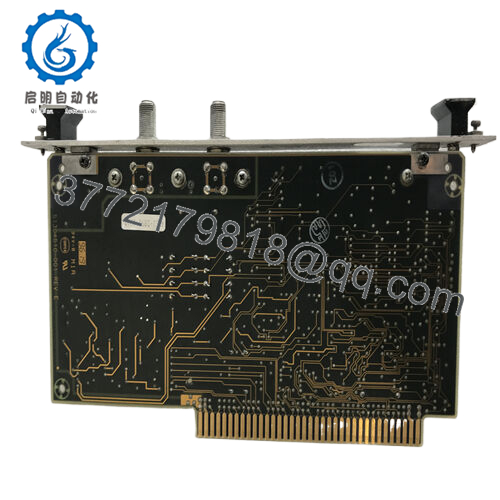

The Honeywell 51304511-200 operates as a high – performance analog input module within the automation architecture, serving as a vital link between field – level analog devices and the central control system. It accepts multiple analog input signals—such as temperature, pressure, and flow measurements—from sensors and transducers, conditions them to filter out noise and interference, and converts them into digital data compatible with the control system’s backplane. This module seamlessly integrates with Honeywell’s TDC 3000 and Experion PKS control platforms, leveraging the system’s backplane infrastructure to ensure fast and accurate data transmission.

51304511-200

A key feature of the Honeywell 51304511-200 is its high – resolution analog – to – digital conversion, which preserves the precision of raw sensor data, making it ideal for applications where minute changes in process variables must be detected. Additionally, it incorporates advanced isolation technology to protect against ground loops and voltage spikes, a common issue in industrial settings that can corrupt signal integrity.

51304511-200

Technical specifications:

Model Number 51304511-200

Brand Honeywell

Type Analog Input Module

Input Voltage 12 – 24V DC

Operating Temp Range- 10°C to 60°C

Mounting StyleBackplane – Mounted

Dimensions155mm x 95mm x 75mm

Weight400g

Interface/BusTDC 3000 Backplane

ComplianceCE, UL, RoHS

Supported ProtocolsCompatible with TDC 3000 system protocols

Typical Power Draw4.5W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

51304511-200

Main features and advantages:

Redundancy is a critical requirement in mission – critical industrial systems, and the Honeywell 51304511-200 is compatible with redundant backplane configurations. This ensures that in the event of a primary module failure, a backup unit can take over seamlessly, preventing data loss and maintaining uninterrupted operation. The module is equipped with built – in diagnostic tools that continuously monitor its performance, including input signal quality, conversion accuracy, and internal component health. These diagnostics provide real – time alerts through the control system interface, enabling engineers to address potential issues before they affect process stability. Its design is optimized for easy integration into existing control systems, with a form factor that fits standard backplane slots, reducing the complexity of upgrades or replacements.

Choosing the Honeywell 51304511-200 delivers tangible benefits in real – world industrial operations. Its high – precision analog – to – digital conversion ensures that process variables are measured with exceptional accuracy, leading to tighter control loops and improved product quality. In manufacturing environments, this translates to reduced waste and consistent output. The module’s robust noise filtering capabilities minimize the impact of electrical interference, ensuring that even weak analog signals from distant sensors are processed reliably—critical in large – scale facilities like chemical plants or refineries. Engineers will appreciate its long – term reliability, as the Honeywell 51304511-200 is engineered to withstand harsh industrial conditions, reducing maintenance cycles and lowering total ownership costs. Its seamless integration with Honeywell’s control platforms also reduces engineering overhead during system design and commissioning.

51304511-200

Application areas:

The Honeywell 51304511-200 finds widespread application across industries where precise analog signal processing is essential. In the oil and gas sector, it is used to monitor pressure and flow rates in pipelines, ensuring safe and efficient transportation of hydrocarbons. In power generation facilities, the module processes temperature and vibration data from turbines and generators, providing critical insights for preventive maintenance and operational efficiency. In pharmaceutical manufacturing, where strict process control is mandated, the Honeywell 51304511-200 ensures accurate monitoring of parameters like pH levels and temperature in bioreactors, supporting compliance with regulatory standards. Its ability to perform reliably in these demanding environments—whether exposed to high humidity, corrosive fumes, or electrical noise—makes it a trusted component in critical systems.

Related products:

HONELYWELL FC-QPP-0002

HONELYWELL 51301874-100

HONELYWELL 51196694-904

HONEWELL 80363969-150

HONEWELL FC-USI-0002

HONELYWELL CC-PUIO31

HONELYWELL CC-PUIO01

HONELYWELL CC-TUIO01

HONELYWELL CC-PWR401

HONELYWELL CC-PFB401

HONELYWELL FC-PSU-UNI2450U

HONELYWELL FC-TSRO-0824

HONELYWELL FC-RUSIO-3224

HONELYWELL FC-TSRO-08UNI

HONEWELL CC-PUI031

HONEWELL TP-DSOEP1-100

HONEWELL TP-OPADP1-200

HONELYWELL FC-IOCHAS-0001R

HONELYWELL FC-RUSIO-3224

HONEWELL NE-FWMB01

HONEWELL CC-PWRB01

HONELYWELL LG1093AA24

HONELYWELL CC-PUIO31

HONELYWELL FC-IO-0002

HONELYWELL FS-FEEDER-24R

HONEWELL 05704-A-0145

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626