Description

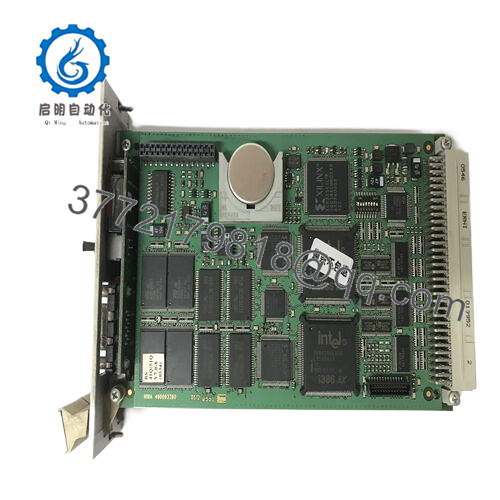

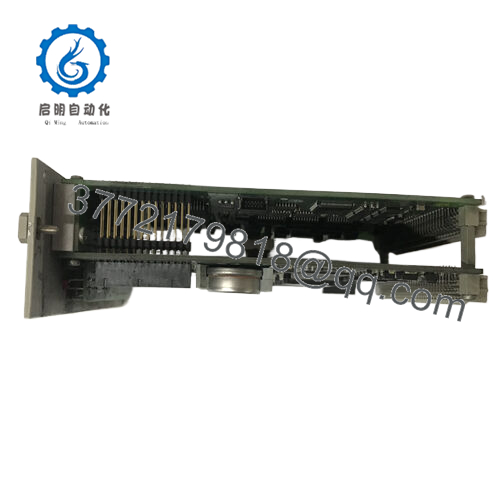

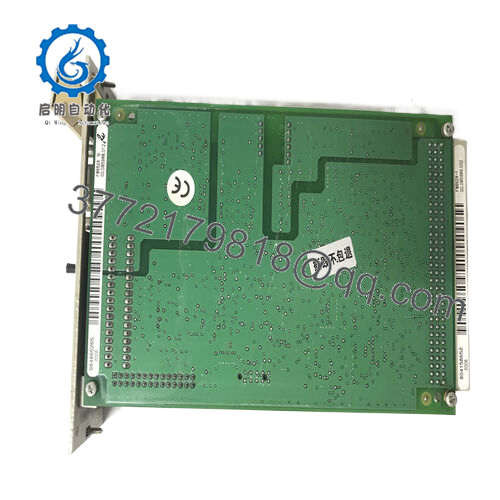

Model: HIMA F8652X 984865265

- Manufacturer: HIMA Paul Hildebrandt GmbH

- Series: HIMax / HIQuadX Safety Systems

- Product Type: Central Processing Unit (CPU) Module

- Safety Standard: IEC 61508 SIL3 certified

- Application: Emergency Shutdown (ESD), Fire & Gas (F&G), Turbine Protection, Burner Management, High-Integrity Process Control

1. Industry Background

Industrial operations in oil & gas, refining, power generation, and chemical plants face constant risks—ranging from toxic gas leaks to turbine overspeed conditions. To mitigate these hazards, facilities implement Safety Instrumented Systems (SIS) that can automatically bring the plant to a safe state.

At the center of these SIS platforms are safety-certified controllers capable of real-time monitoring, logic execution, and fail-safe decision making. The HIMA F8652X 984865265 is one of HIMA’s most advanced CPU modules, specifically engineered to deliver high availability, scalability, and compliance with SIL3 standards.

2. Role of the HIMA F8652X

The F8652X functions as the brain of the HIMax system, executing safety logic and coordinating input/output processing across the rack. It:

- Processes safety logic written in HIMA’s programming environment (ELOP II Factory).

- Communicates with digital and analog I/O modules (e.g., F7131, F3237, F8621A).

- Manages redundancy to achieve fault tolerance and zero downtime.

- Interfaces with supervisory systems (DCS, SCADA) through secure communication protocols.

In many installations, two or more F8652X modules are configured in redundant architectures. If one CPU fails, the backup takes over instantly—ensuring uninterrupted protection.

- F8652X 984865265

- F8652X 984865265

3. Technical Highlights

Performance Features

- High-Performance CPU Core: Handles complex safety applications with fast scan cycles.

- Redundancy Support: Designed for 1oo2 (one out of two) or 2oo3 (two out of three) voting architectures.

- SIL3 Certification: Fully compliant with IEC 61508 for use in critical safety applications.

- Hot-Swappable: CPU replacement possible without shutting down the entire system.

- Deterministic Processing: Guarantees predictable response times under all load conditions.

Reliability Features

- Fault Tolerant Operation: Detects and isolates hardware faults automatically.

- Online Diagnostics: Continuous monitoring of CPU health and communication status.

- Watchdog Functionality: Ensures automatic switch to safe state in case of system error.

- Rugged Construction: Industrial-grade design for extreme temperature, vibration, and EMC conditions.

4. Technical Specifications (Typical for HIMA F8652X)

| Specification | Detail |

|---|---|

| Model | F8652X 984865265 |

| Type | CPU Module / Safety Controller |

| System Platform | HIMax / HIQuadX |

| Safety Integrity | SIL3 (IEC 61508) |

| Processor | High-performance redundant-capable CPU |

| Redundancy | 1oo2 / 2oo3 supported |

| Hot-Swap | Yes |

| I/O Handling | Supports digital, analog, and specialty I/O modules |

| Communication | Ethernet, safe communication bus for HIMA I/O modules |

| Diagnostics | Full online diagnostics with fault localization |

| Typical Applications | ESD, F&G, BMS, turbine safety, high-integrity process protection |

5. Application Areas

The F8652X is found in some of the most demanding industrial safety environments:

- Oil & Gas Production & Refining

- Wellhead control

- Pipeline safety interlocks

- Refinery ESD systems

- Chemical & Petrochemical Plants

- Reactor emergency shutdown

- Overpressure protection systems

- Toxic gas monitoring

- Power Generation

- Turbine overspeed protection

- Boiler safety controls

- Generator trip systems

- Marine & Offshore

- FPSO safety systems

- Fire & gas shutdown logic

- Offshore drilling rig ESD

- Industrial Manufacturing

- Burner Management Systems (BMS)

- Safety interlocks for hazardous material processes

6. Benefits for Operators

- Reduced Risk: Provides compliance with global safety regulations.

- Maximum Uptime: Fault-tolerant architecture keeps processes online even during hardware issues.

- Scalability: Fits both small SIS applications and large multi-rack installations.

- Lifecycle Support: Long availability ensures decades of system service life.

- Maintenance-Friendly: Hot-swap and diagnostics reduce mean time to repair (MTTR).

7. Installation and Maintenance Best Practices

Installation Tips

- Mount in approved HIMA HIMax rack with proper grounding.

- Always configure redundancy before commissioning.

- Verify compatibility with power supply and I/O modules.

- Follow HIMA wiring and shielding guidelines to prevent noise interference.

Maintenance Guidelines

- Use HIMA diagnostic tools for regular health checks.

- Keep at least one spare F8652X in stock for critical plants.

- Update firmware periodically for cybersecurity and performance enhancements.

- Train operators on proper CPU replacement under hot-swap conditions.

8. Related Modules and System Integration

The F8652X CPU works in combination with:

- HIMA F7131 – Digital Input Module

- HIMA F3237 – High-Density Input Card

- HIMA F8621A – Digital Output Module

- HIMA X-SB01 – Terminal Base Module

- HIMA F7553 – Logic Controller

- HIMA F3330 – Power Supply Unit

Together, these components form a scalable HIMax architecture capable of handling thousands of I/O points across distributed racks.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626