Description

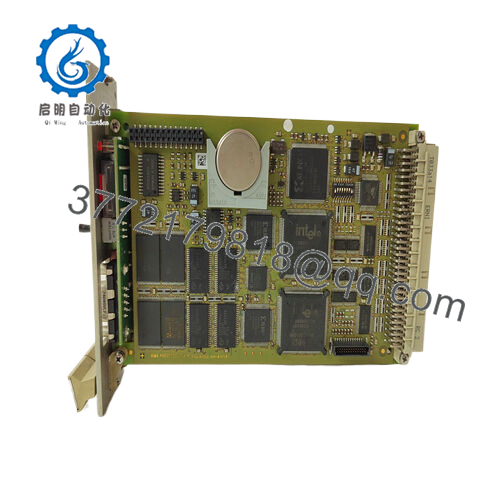

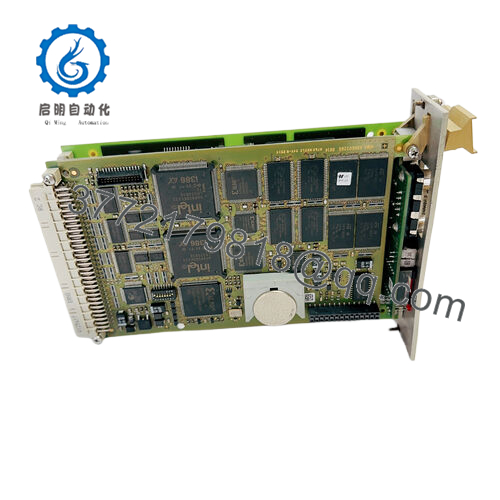

Product Model: HIMA F8650X 984865065

- Brand: HIMA

- Series: HIMA F-Series (HIQuadX Safety Systems)

- Product Type: CPU / Central Processing Module

- Key Features:

- SIL3-certified fail-safe processor for safety-critical automation

- Redundancy support for high availability applications

- Optimized for emergency shutdown, fire & gas, and turbine protection systems

- Integrated diagnostics and communication capabilities

- F8650X 984865065

- F8650X 984865065

Industrial Context and Market Need

In modern process industries — from oil refineries to nuclear power plants — operational safety depends on reliable decision-making inside the safety instrumented system (SIS). A minor fault in the control logic can escalate into catastrophic events. The central processor is therefore the brain of the safety system, ensuring inputs are evaluated, logic executed, and outputs commanded with uncompromised integrity.

The HIMA F8650X 984865065 CPU module plays exactly this role. As part of the HIQuadX safety platform, it provides the computing intelligence behind emergency shutdowns, fire & gas systems, burner management systems, and turbine safety. Its redundant architecture and SIL3 certification make it one of the most trusted safety CPUs in high-risk industries.

Role of the HIMA F8650X in Safety Systems

The F8650X is the central processor unit (CPU) responsible for:

- Executing the safety logic programmed by engineers using SILworX software

- Processing digital and analog inputs from modules such as the F3237 digital input card

- Sending safe control outputs via modules like the F8621A digital output card

- Monitoring system health, communication, and redundancy status

- Managing diagnostics to detect failures at both the module and loop level

Essentially, without the F8650X, the entire HIQuadX safety controller would lack the intelligence to take preventive or corrective actions during process upsets or emergencies.

Technical Features and Benefits

The HIMA F8650X 984865065 comes with an array of advanced technical features that benefit both operators and engineers:

Key Features

- High-Performance CPU: Ensures deterministic execution of safety logic with minimal cycle times.

- Fail-Safe Design: Automatically transitions to a safe state in case of processor fault.

- Redundancy Ready: Supports dual CPU configurations to eliminate single points of failure.

- Integrated Communication: Interfaces seamlessly with field I/O modules and system buses.

- Advanced Diagnostics: Self-monitoring with detailed fault logs for predictive maintenance.

- Hot-Swappable: CPU module can be replaced without shutting down the entire rack.

- Certification: Fully compliant with IEC 61508 SIL3 and IEC 61511 safety standards.

Operator Advantages

- Uninterrupted Plant Operation: Redundant CPU capability ensures availability even during module failure.

- Compliance Assurance: Meets global safety requirements for regulated industries.

- Ease of Maintenance: Hot-swap support and predictive diagnostics cut downtime.

- Scalable Control: Capable of supporting small safety loops or large, multi-node architectures.

Technical Specifications

| Specification | Details |

|---|---|

| Model | HIMA F8650X 984865065 |

| Type | Central Processing Unit (CPU) |

| System | HIMA HIQuadX Safety System |

| Safety Integrity | SIL3 (IEC 61508 certified) |

| Processor Functions | Executes safety logic, diagnostics, redundancy management |

| Redundancy | Dual CPU option for high availability |

| Diagnostics | Built-in self-tests, fault monitoring, error logs |

| Mounting | Rack-mounted, hot-swappable |

| Compliance | IEC 61508, IEC 61511, EN 50156 |

| Applications | ESD, Fire & Gas, BMS, Turbine Safety, Power Plant Safety |

Applications Across Industries

The HIMA F8650X CPU is applied in critical safety domains where high-integrity control is mandatory:

- Oil & Gas: Executes shutdown sequences to protect personnel and assets during process deviations.

- Chemical Plants: Controls interlocks and safeguards reactors and pipelines.

- Power Generation: Deployed in turbine protection systems, auxiliary boiler shutdowns, and emergency interlocks.

- Refining & Petrochemicals: Central processor for fire and gas detection systems.

- Pharmaceutical Manufacturing: Ensures compliance with international safety standards while maintaining uptime.

- Offshore Platforms: Engineered for harsh marine environments, delivering continuous safety supervision.

Installation and Maintenance Insights

Installation Best Practices:

- Install the F8650X in a HIMA HIQuadX rack with proper grounding.

- Configure redundancy when plant safety requires high availability.

- Validate logic execution cycles through SILworX engineering tools.

- Perform commissioning checks to confirm integration with input/output modules.

Maintenance Recommendations:

- Review diagnostic logs regularly for early signs of degradation.

- Conduct periodic proof testing to maintain SIL3 compliance.

- Keep firmware aligned with the latest HIMA-certified versions.

- Use hot-swap capability for CPU replacement without halting plant operation.

Related HIMA Modules

To function effectively, the F8650X CPU works with complementary modules:

- HIMA F3237 – Digital input module for acquiring fail-safe signals

- HIMA F8621A – Digital output module for control actions

- HIMA F7553 – Safety logic processor card (alternative CPU module)

- HIMA F3330 – Power supply unit for reliable system operation

- HIMA F7113 – Digital input variant for specific monitoring applications

- HIMA F6705 – Communication processor for interfacing with plant DCS systems

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626